7

Regulations on robot safety

Thoroughly read the regulations below before use.

WARNING

If the moving workpiece poses a risk to personnel or if

human ngers could be caught in the nger attachment,

install safety measures such as a protective cover, etc.

If the circuit pressure drops due to power failure or

air source trouble, the gripping power may

decrease and the workpiece may fall. Provide

position locking measures, etc., so that personnel

are not injured or machines damaged.

CAUTION

Working environment

At cutting, casting, or welding plants, there is a risk of foreign

matter, such as cutting uid, chips, powder and dust,

entering the equipment. Use covers and such to prevent this

as much as possible.

Do not use the equipment under the following environments.

Exposed to coolant (because the sliding section is

abraded by abrasive or polishing debris in the liquid)

When the atmosphere contains organic solvents,

chemicals, acids, alkalis, kerosene, etc.

Exposed to water

When gripping long or large workpieces, stable

gripping requires a grip on the center of gravity.

Stability is a must when using larger or multiple

workpieces as well.

◎

: Excellent,

〇

: Acceptable,

△

: Conditional,

×

: Unusable

Select a model with sufcient power to grip the

workpiece weight.

Select a model with sufcient opening/closing width

for the workpiece size.

If directly inserting the workpiece into the jig with

the gripper, consider relief during design. The

gripper may be damaged.

◎

W

L

○

W

L

△

W

L

×

W

L

Pneumatic components

Safety Precautions

Be sure to read this section before use.

Refer to Pneumatic Cylinders (CB-030SA) for general information of the cylinder and cylinder

switches.

Product-specic cautions: Grippers for collaborative robots

ISO 10218, JIS B 8433 (Robots and robotic devices)

ISO/TS 15066 (Robots and robotic devices)

Design/selection

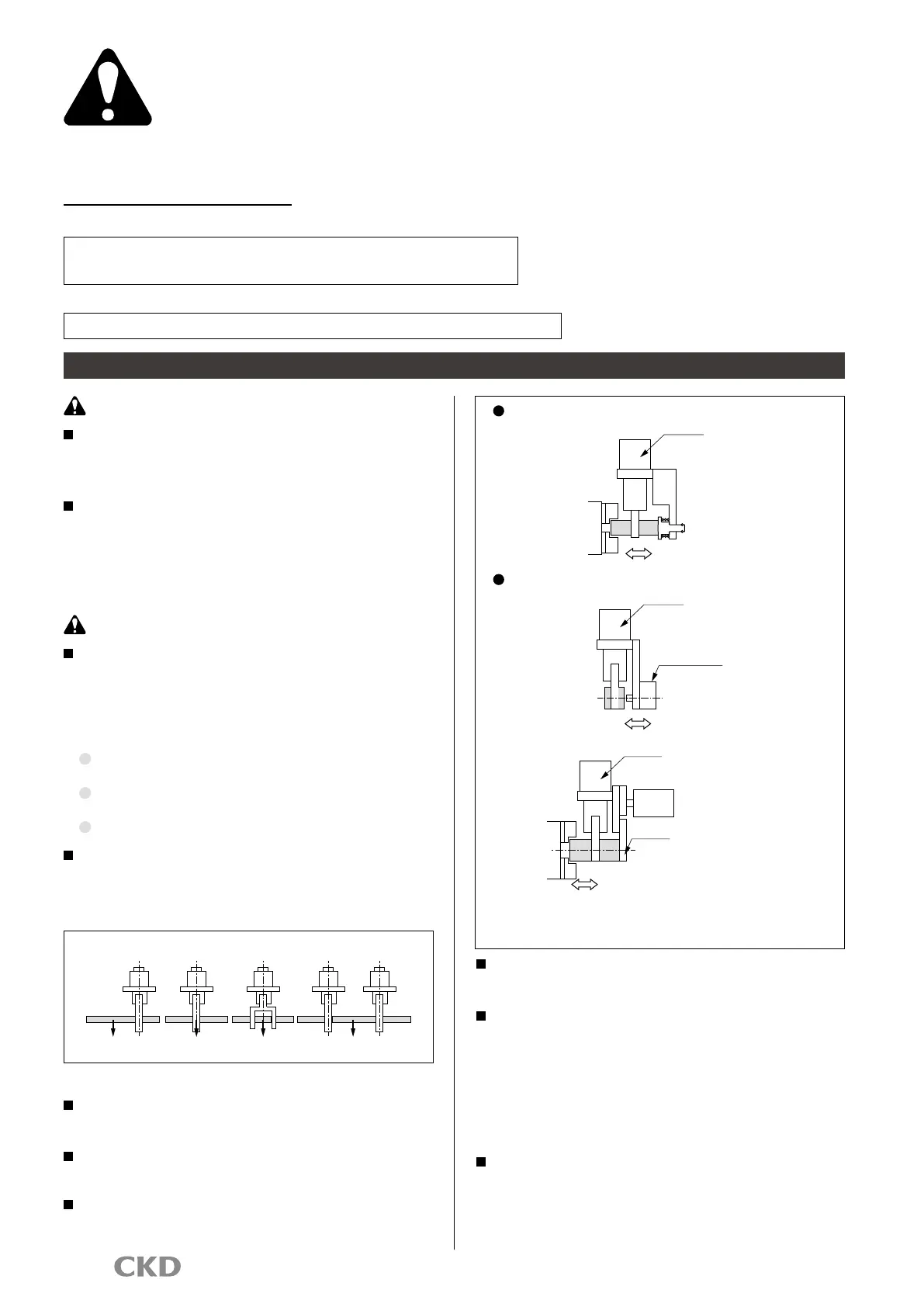

If the attachment is not rigid enough, the resulting sag

could cause the nger to twist or adversely affect operation.

Adjust the gripper open/close speed with the speed

controller.

When used at high speed, backlash may occur sooner.

In addition, the workpiece may vibrate due to

shocks in opening/closing, which may lead to

erroneous gripping, erroneous insertion of

workpieces and poor repeatability.

Condensation (water drops) may occur in the piping

in certain conditions if an actuator with small bore

size/short stroke is operated at high frequency.

Take measures against condensation with a quick

exhaust valve, etc.

Gripper

Gripper

Push cylinder

Gripper

Mini slide

mechanism

Stopper

When using push cylinder

Push-in jig with ejector

Note) Since the workpiece slides over the top of the attachment, it may

signicantly shorten the service life of the gripper. The shape of the

attachment should be sufciently considered.

Loading...

Loading...