Do you have a question about the Omron R6Y Series and is the answer not in the manual?

General safety guidelines and warning classifications for robot operation.

Crucial safety precautions for robot handling and operation.

Requirements and qualifications for personnel operating industrial robots.

Explanation of built-in safety features like overload and overheat detection.

Safety considerations for integrated automated systems involving robots.

Procedures for conducting a safe trial run after installation and adjustments.

Guidelines for performing tasks safely inside the robot's protective enclosure.

Procedures and precautions for operating the robot in automatic mode.

Details of the OMRON robot warranty terms and conditions.

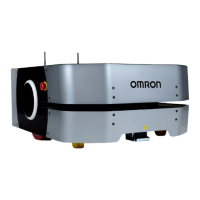

Description of the robot's mechanical structure and axis movements.

Overview of the YRC robot controller unit.

List of initialization numbers for different robot models.

Environmental requirements for safe and optimal robot installation.

Specifies the environmental conditions required for robot installation.

Guidelines for preparing a rigid and stable installation base for the robot.

Step-by-step guide for unpacking and installing the robot.

Procedures for safely unpacking the robot and its accessories.

Instructions for verifying the product configuration and condition after unpacking.

Safe procedures for moving the robot manipulator to the installation site.

Instructions for securely mounting the robot onto the installation base.

Procedures for grounding the robot and controller to prevent electrical shock.

Instructions for connecting robot cables to the controller.

Guidelines for connecting external wiring and air tubes.

Procedures and considerations for mounting end effectors onto the robot arm.

Limits on R-axis load inertia and acceleration coefficients for safe operation.

Formulas for calculating the moment of inertia of attached loads.

Practical example demonstrating moment of inertia calculation for a load.

Methods for attaching end effectors to the manipulator, including load limits.

Ensuring sufficient gripping force to prevent workpiece loss during operation.

How to adjust movement limits using X-axis mechanical stoppers on the R6YXX1200 model.

Procedure for changing X-axis mechanical stopper positions on the R6YXX1200.

Instructions for installing additional mechanical stoppers on X, Y, and Z axes for specific models.

Steps for installing additional mechanical stoppers to limit movement range.

Procedure for installing additional mechanical stoppers on X and Y axes.

Instructions for installing additional mechanical stoppers on the Z-axis.

Information on overrun amounts when the robot strikes mechanical stoppers.

Diagrams showing robot working envelopes and stopper positions.

Data on robot stopping characteristics during emergency stops.

Stopping time and distance graphs for XY axes of specific robot models.

Stopping time and distance graphs for XY axes of the R6YXX1200 model.

Introduction to the robot adjustment procedures.

Safety measures to be followed before attempting robot adjustments.

Procedures for setting and adjusting the robot's origin position.

Methods for performing absolute reset to detect the origin position.

Using proximity sensors for absolute reset on X, Y, and R axes.

Using visual marks for absolute reset on X, Y, and R axes.

Using mechanical stoppers for absolute reset on the Z-axis.

Explanation of machine reference value and its adjustment.

Detailed steps for performing absolute reset on robot axes.

Performing absolute reset using sensor method via PB or RS-232C.

Absolute reset procedures using marks for X, Y, and R axes.

Procedure for re-setting absolute encoder with servo on.

Procedure for re-setting absolute encoder with servo off.

Procedure for performing a new absolute reset with servo on.

Procedure for performing a new absolute reset with servo off.

Absolute reset procedure for the Z-axis using the stroke end method.

Steps for changing the origin position and adjusting the machine reference.

Adjusting machine reference using the sensor method for X, Y axes.

Adjusting X-axis machine reference for specific robot models.

Changing the origin position using the mark method.

Adjusting Z-axis machine reference using the stroke end method.

How to configure software limits to define the robot's working envelope.

Steps to set standard coordinate systems for optimized operations.

Instructions for applying identification stickers to robot components.

Procedures for safely removing robot covers for maintenance.

Guide for adjusting timing belt tension on Z and R axes.

Procedure for adjusting timing belt tension on specific robot models.

Procedure for adjusting timing belt tension on the R6YXX1200 model.

Introduction to periodic inspection items and procedures for OMRON X series robots.

Important precautions to observe during periodic robot inspections.

Daily checklist for robot inspection before and after operation.

Specific inspection tasks to be performed every six months.

Procedures and precautions for replacing harmonic drives on robot axes.

Guidelines for determining the harmonic drive replacement schedule.

General procedures and safety measures for harmonic drive replacement.

Harmonic drive replacement steps for specific robot models.

Harmonic drive replacement steps for the R6YXX1200 model.

Steps for replacing grease in RV speed reduction gears for specific models.

Guidance on the recommended period for replacing RV speed reduction gear grease.

Specifies the type of grease recommended for RV speed reduction gears.

Detailed procedures and precautions for replacing RV speed reduction gear grease.

Procedure for replacing grease in the X-axis speed reduction gear (specific models).

Procedure for replacing X-axis grease for models manufactured after Oct 2009.

Procedure for replacing grease in the Y-axis speed reduction gear (specific models).

Procedure for replacing Y-axis grease for models manufactured after Oct 2009.

Methods to improve robot cycle time through programming techniques.

Using arch motion programming to shorten cycle time.

Optimizing acceleration by adjusting the axis tip weight parameter.

Utilizing the tolerance parameter to increase speed for non-critical points.

Adjusting OUT effective position for faster chucking operations.

Detailed specifications of the robot manipulator, including dimensions and capabilities.

Core technical specifications for different robot models like arm length and payload.

Visual representations and detailed dimensions of robot models.

Diagrams illustrating the internal wiring connections of the robot.

Tables detailing wire signals, colors, and connections for robot cabling.