3-33

CHAPTER 3 Installation

6-4 Attaching the end effector

The manipulator part to which an end effector is attached must have adequate

strength and rigidity, as well as gripping force to prevent positioning errors. Ta-

ble 3-1 shows the maximum load that can be applied to the end effector attach-

ment of each robot model. Recommended methods for attaching end effectors

are shown in Table 3-2 and Fig. 3-41. Refer to Fig. 3-39 for details on the end

effector attachment of each robot model.

When checking end effector operation, refer to "6 Trial Operation" in Chapter 1.

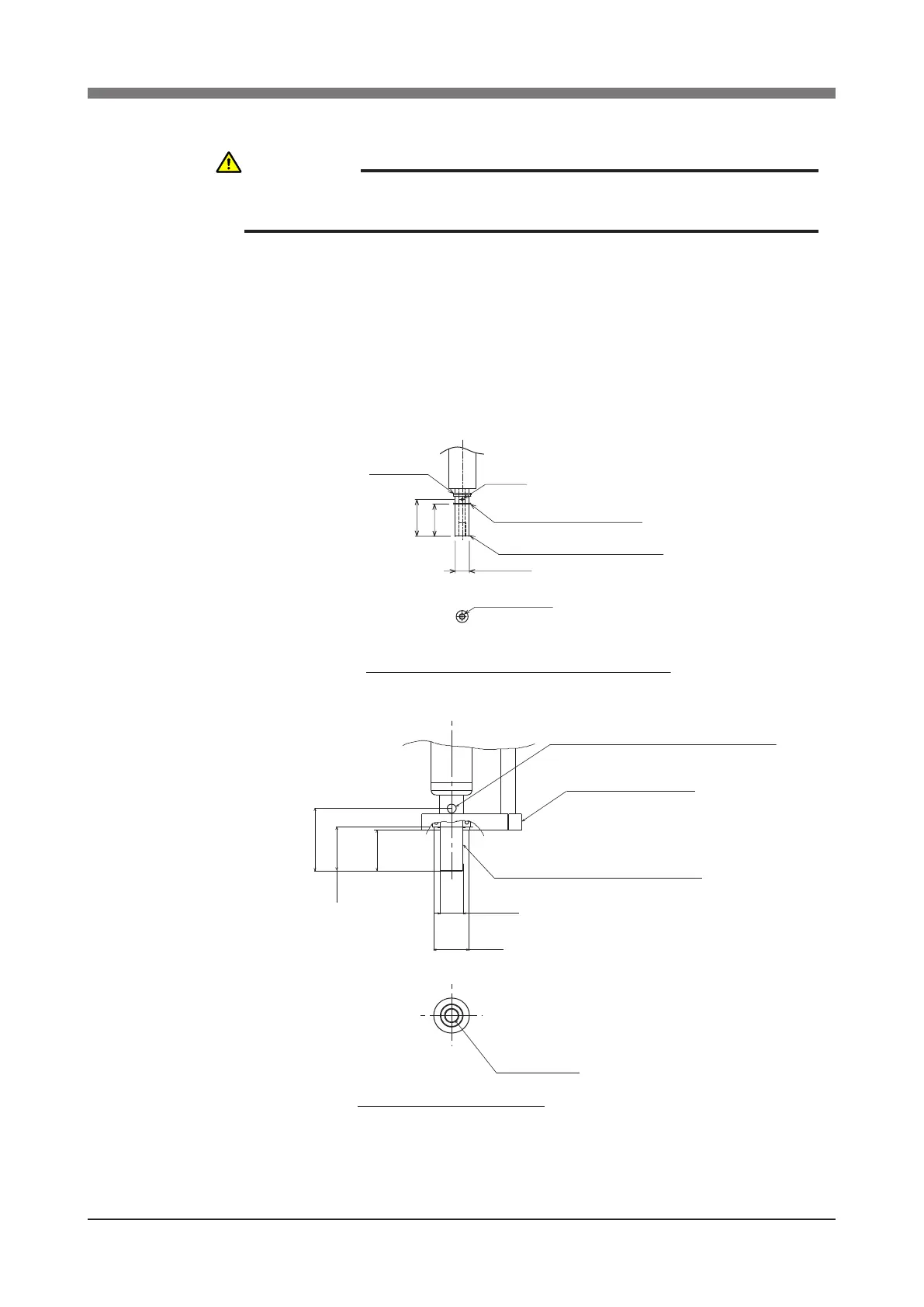

Fig. 3-39 (1)

M16´2 depth25

Support shaft clamp plate

25

-0.01

-0.02

39

69

45

47.8

R6YXX1200: Z-axis tip shape

∅10

+0.2

0

Spline shaft (hollow): hollow diameter ∅12

(Hole for attaching user tool or

R-axis rotation during direct teaching)

∅

∅

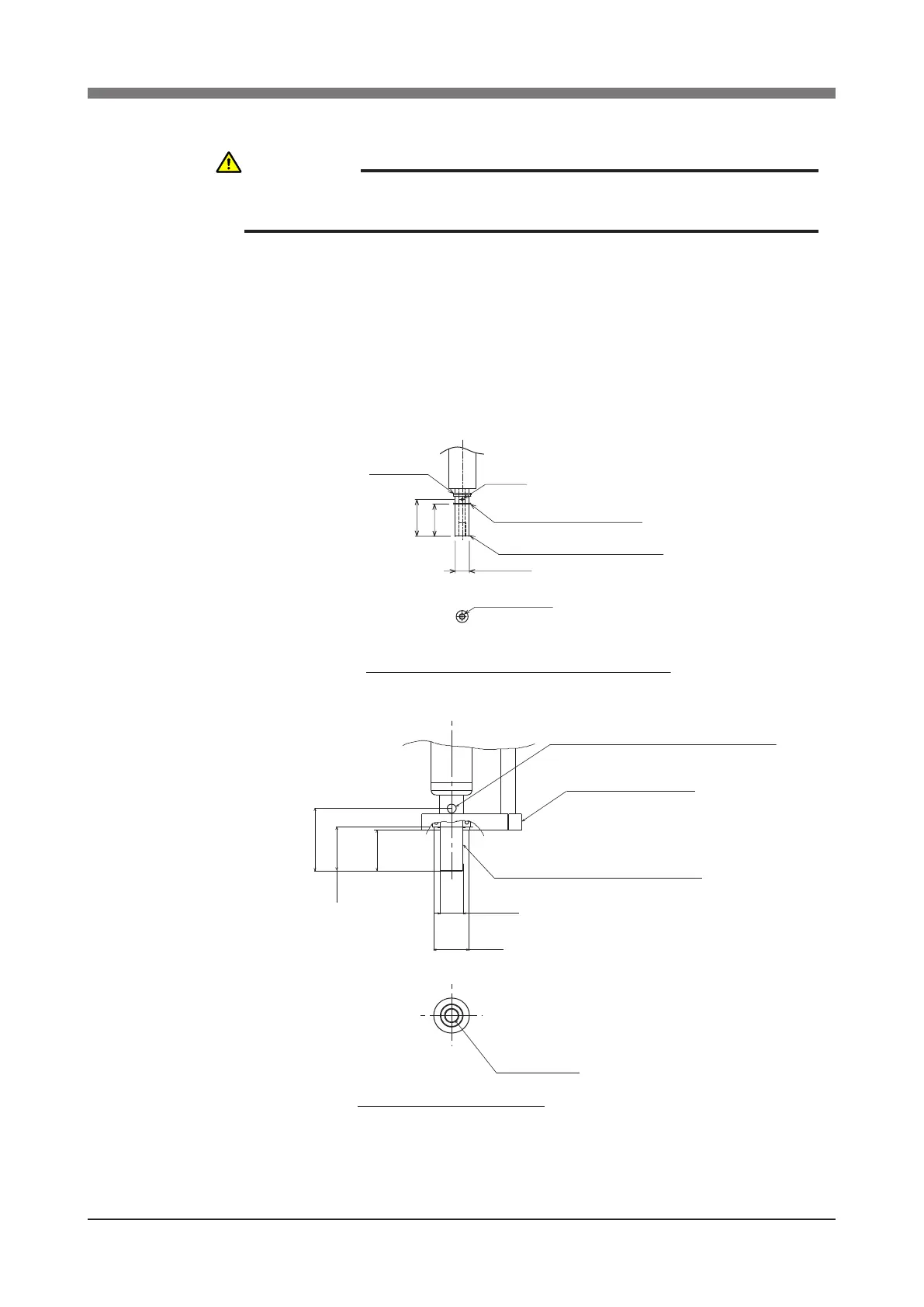

Fig. 3-39 (2)

R6YXH250, R6YXH350, R6YXH400: Z-axis tip shape

41

36

3

0

+0.2

16h7

-0.018

0

Z-axis mechanical

stopper

(Hole for attaching user tool or

R-axis rotation during direct teaching)

Retaining ring to set the user tool

(See cautions on page 3-55.)

Spline shaft (hollow): hollow diameter 7

M8×1.25, depth 15

∅

∅

∅

WARNING

BEFORE ATTACHING THE END EFFECTOR, BE SURE TO TURN OFF THE

CONTROLLER.

Loading...

Loading...