3-3

CHAPTER 3 Installation

1-2 Installation base

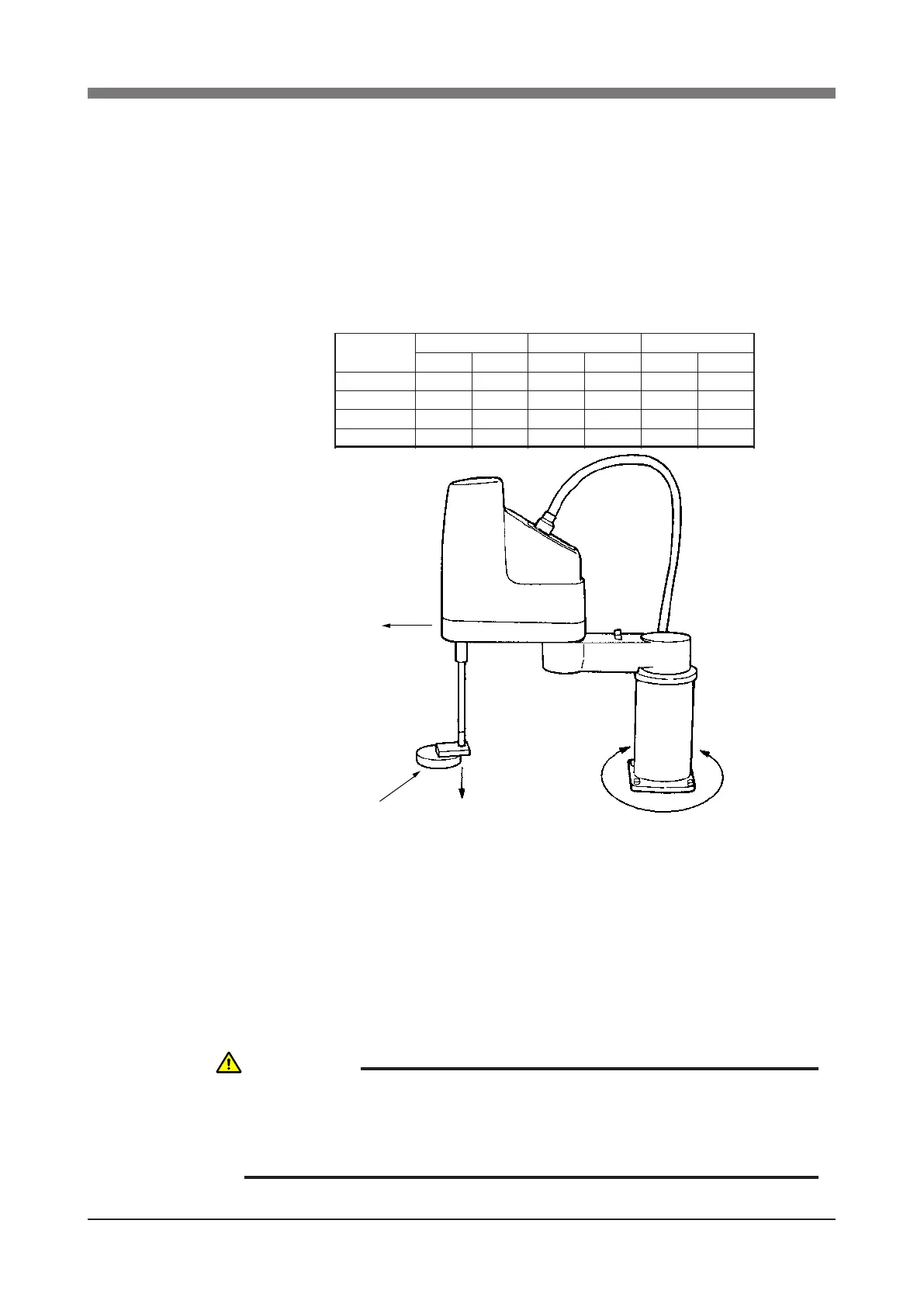

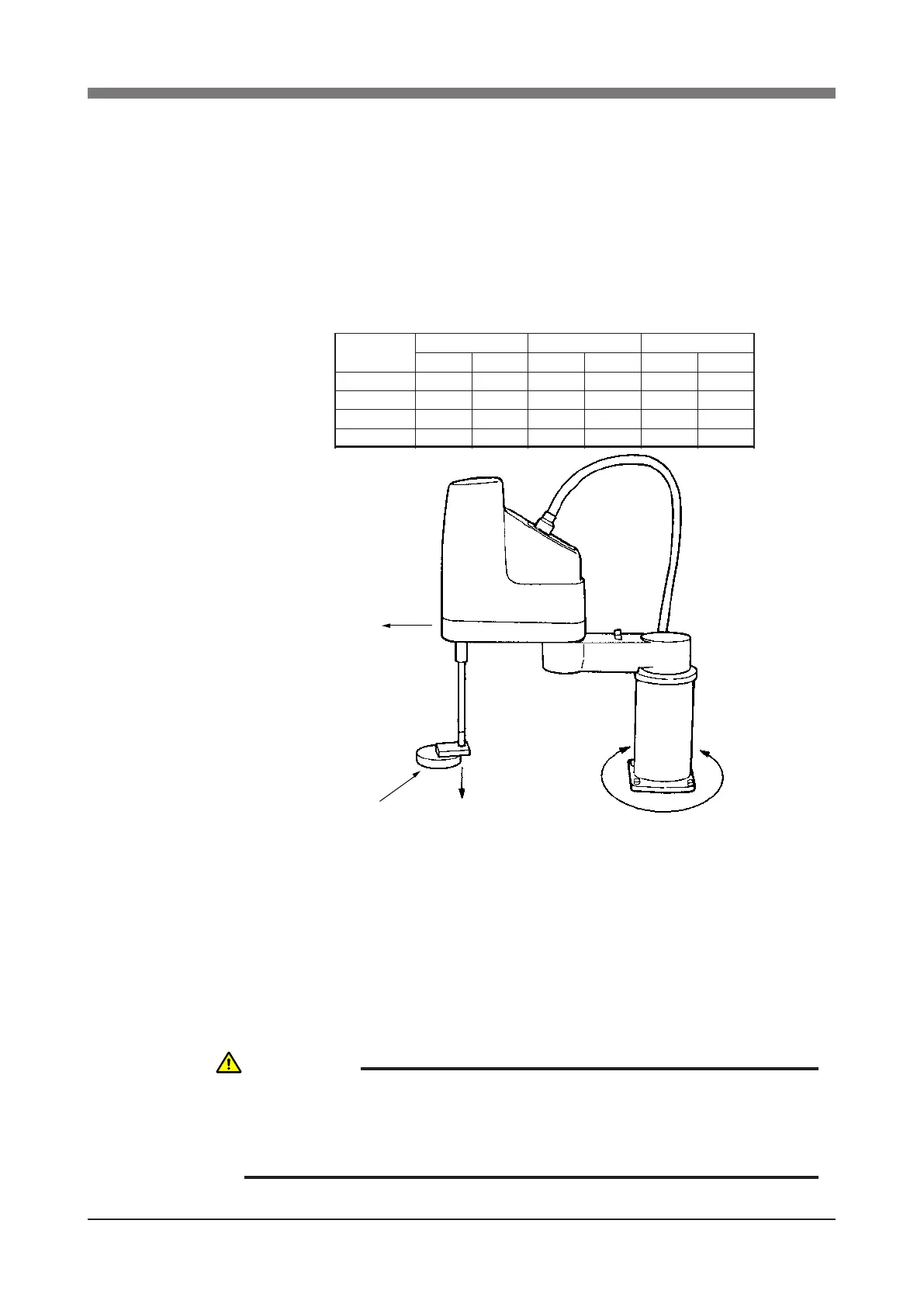

1) Prepare a sufciently rigid and stable installation base, taking account of

the robot weight including the end effector (gripper), workpiece and reac-

tion force while the robot is operating. The maximum reaction force (see

Fig. 3-1) applied to the X-axis and Z-axis of each robot during operation is

shown in the table below. These values are an instantaneous force applied

to the robot during operation and do not indicate the maximum load capac-

ity.

The maximum reaction force

Robot Model

R6YXH250

R6YXH350

R6YXH400

N kgf Nm kgfm N kgf

305 31 56 6 40 4

330 34 56 6 40 4

391 40 56 6 40 4

336

1029 105 108

F

X

max M

X

max F

Z

max

R6YXX1200

3293

11

Fig. 3-1 Maximum reaction force applied during operation

2) The parallelism of the installation base surface must be machined within a

precision of ±0.05mm/500mm. The robot base mount must be installed fac-

ing down and in a level position.

3) Tap holes into the surface of the installation base. For machining dimen-

sions and positions, refer to "1-2 External view and dimensions" in Chapter

7.

4) Securely x the installation base on the oor with anchor bolts.

WARNING

DO NOT PLACE THE ROBOT ON A MOVING INSTALLATION BASE.

EXCESSIVE LOADS WILL BE APPLIED TO THE ROBOT ARM BY

MOVEMENT OF THE INSTALLATION BASE, RESULTING IN DAMAGE

TO THE ROBOT.

Loading...

Loading...