Cylinder Bore Inspection: Inspect

the

cylinder

bores for scuffing, scratches, wear, and scoring. If

these conditions exist, they must be rebored and

honed for the next oversize piston.

When the appearance

of

cylinder bores is accept-

able and there are no scuff marks, check

the

bores

for

wear

or

out-of-roundness as follows:

1. Check cylinder bore for taper, out-of-round,

and wear with a cylinder bore gauge, tele-

scope gauge,

or

inside micrometer. These

measurements should be taken at four places:

the top and bottom

of

piston ring travel, and

parallel and perpendicular to the axis

of

the

crankshaft.

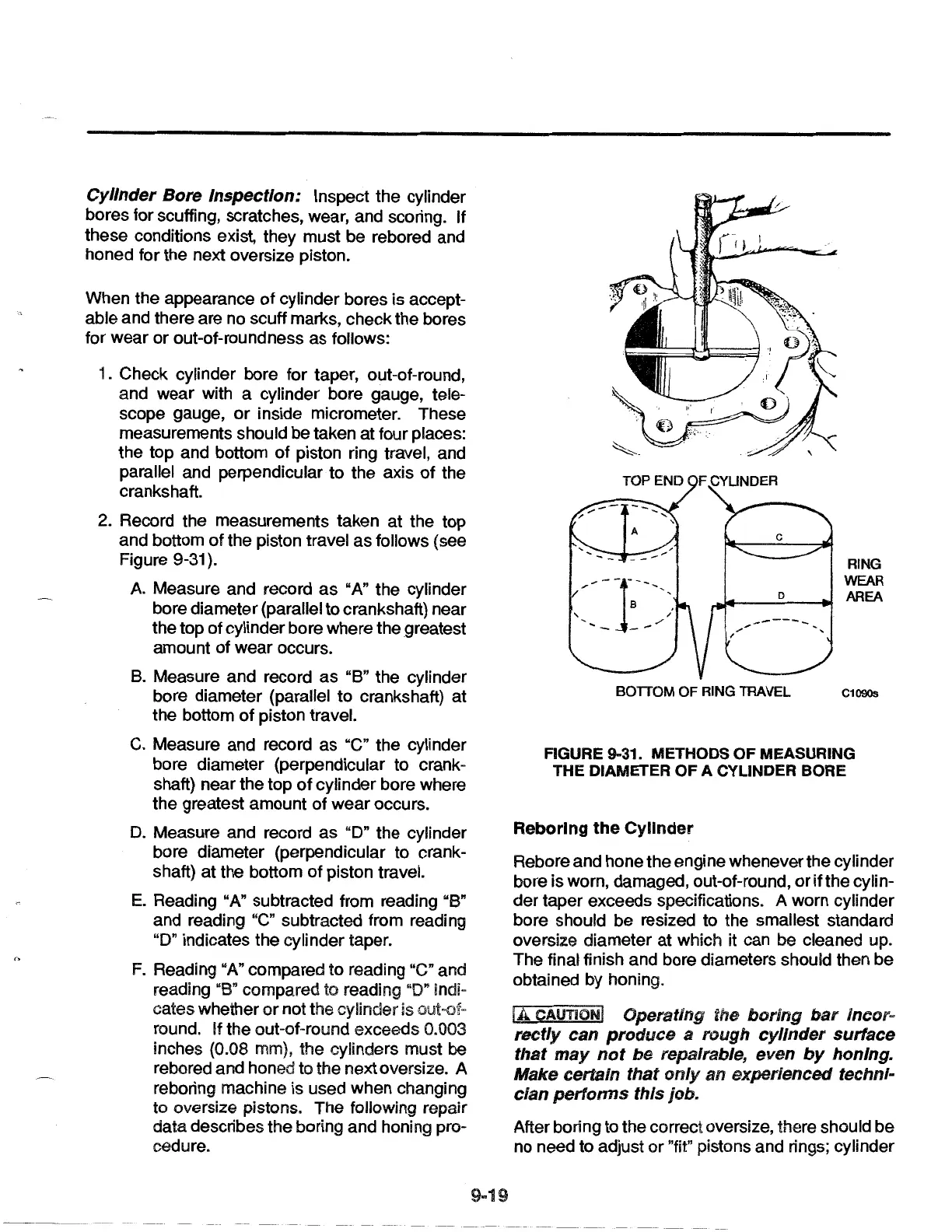

2. Record the measurements taken at the top

and bottom

of

the piston travel

as

follows (see

Figure 9-31

).

A Measure and record

as

"A" the cylinder

bore diameter (parallel to crankshaft) near

the top

of

cylinder bore where the greatest

amount

of

wear occurs.

B.

Measure and record

as

"8"

the cylinder

bore diameter (parallel to crankshaft}

at

the bottom

of

piston travel.

C. Measure and record as "C" the cylinder

bore diameter (perpendicular to crank-

shaft) near the top

of

cylinder bore where

the greatest amount

of

wear

occurs.

D.

Measure and record as "D" the cylinder

bore diameter (perpendicular to crank-

shaft}

at

the bottom

of

piston travel.

E.

Reading "A" subtracted from reading "B"

and reading "C" subtracted from reading

"D" indicates the cylinder taper.

F.

Reading "A" compared to reading "C" and

reading "8" compared to reading "D" indi-

cates whether

or

not the cylinder is out-of-

round. If the out-of-round exceeds 0.003

inches (0.08 mm), the cylinders must be

rebored and honed to the next oversize. A

reboring machine is used when changing

to oversize pistons. The following repair

data describes the boring and honing pro-

cedure.

,--]---~,

/ '

B '

' /

'

./

.....

_

--

D

------

BOTTOM

OF

RING TRAVEL

RING

WEAR

AREA

C1090s

FIGURE 9-31. METHODS OF MEASURING

THE DIAMETER OF A CYLINDER BORE

Reborlng

the

Cylinder

Rebore and hone the engine whenever the cylinder

bore is worn, damaged, out-of-round,

or

if

the cylin-

der

taper exceeds specifications. A worn cylinder

bore should be resized to the smallest standard

oversize diameter

at

which it can be cleaned up.

The final finish and bore diameters should then be

obtained by honing.

lA CAUTION! Operating the

boring

bar

incor~

rectly

can

produce

a rough

cylinder

surface

that

may

not

be

repairable, even

by

honing.

Make certain that

only

an experienced techni-

cian performs this job.

After boring to the correct oversize, there should be

no need to adjust or

"fit" pistons and rings; cylinder

Loading...

Loading...