VALVE SYSTEM

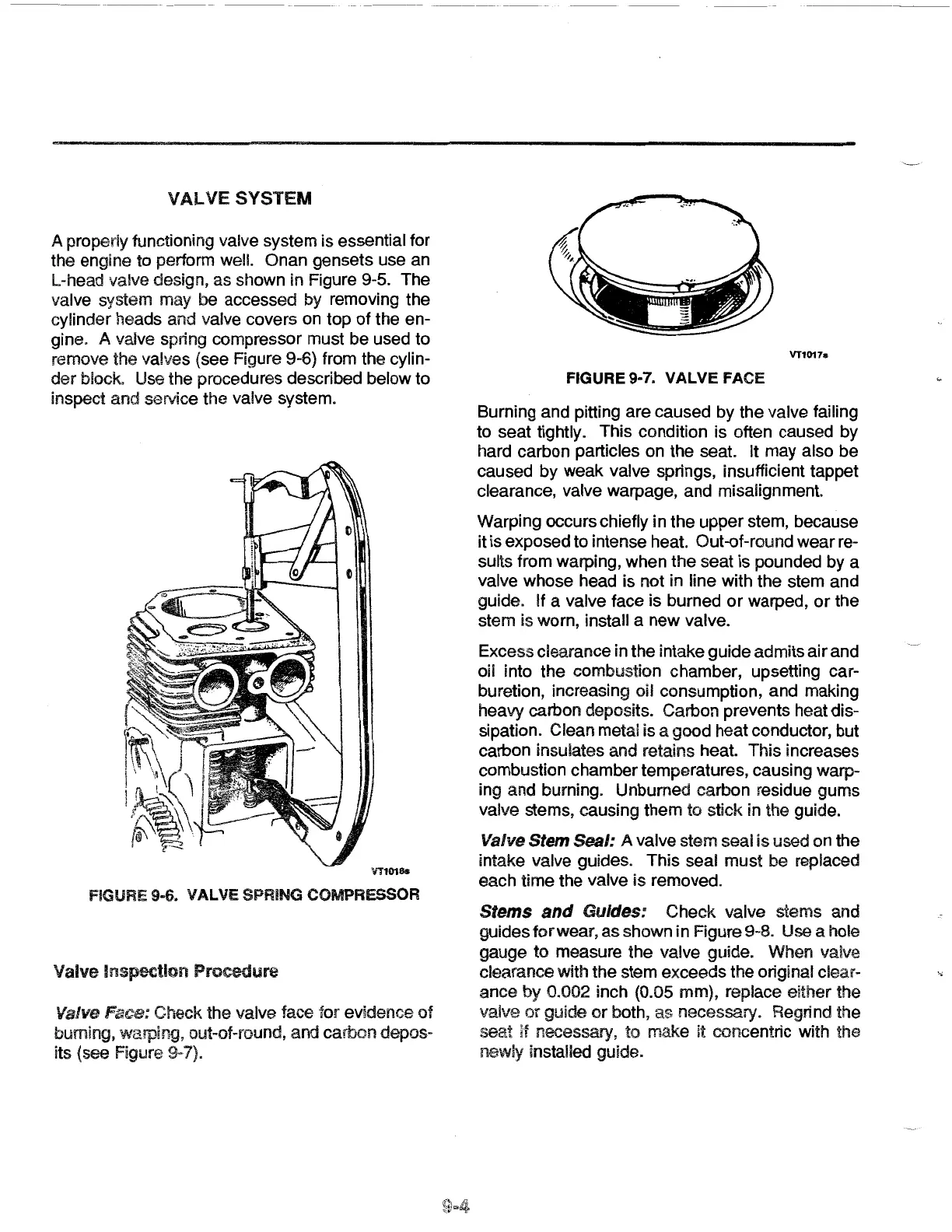

A properly functioning valve system is essential for

the engine to perform well. Onan gensets use an

L-head valve design,

as

shown in Figure 9-5. The

valve system may be accessed by removing the

cylinder heads and valve covers on top

of

the en-

gine.

A valve spring compressor must

be

used to

remove the va!ves (see Figure 9-6) from the cylin-

der

block. Use the procedures described below to

inspect

and service the valve system.

FIGURE 9-6.

VALVE

SPRING COMPRESSOR

Valve Inspection Procedure

Valve Face: Check the valve face for evidence

of

burning, warping, out-of-round, and carbon depos-

its {see Figure 9-7).

VT1017s

FIGURE 9-7.

VALVE

FACE

Burning and pitting are caused by the valve failing

to seat tightly. This condition is often caused by

hard carbon particles

on

the seat. It may also

be

caused by

weak

valve springs, insufficient tappet

clearance, valve warpage,

and

misalignment.

Warping occurs chiefly

in

the

upper

stem, because

it is exposed

to

intense heat. Out-of-round

wear

re-

sults from warping,

when

the

seat is pounded by a

valve whose head is not in line with the stem and

guide. If a valve face is burned

or

warped,

or

the

stem

is worn, install a

new

valve.

Excess clearance in the intake guide admits

air

and

oil into

the

combustion chamber, upsetting car-

buretion, increasing oil consumption, and making

heavy carbon deposits. Carbon prevents heat dis-

sipation. Clean metal is

a

good

heat conductor, but

carbon insulates and retains heat. This increases

combustion chamber temperatures, causing warp-

ing

and

burning. Unburned carbon residue gums

valve stems, causing them

to stick in the guide.

Valve Stem Seal: A valve stem seal

is

used on the

intake valve guides.

This

seal

must

be replaced

each time

the

valve

is

removed.

Stems

and

Guides:

Check

valve stems and

guides

for

wear,

as

shown

in

Figure 9-8. Use a hole

gauge

to

measure

the

valve guide. When valve

clearance with

the

stem exceeds

the

original clear-

ance

by 0.002 inch (0.05 mm), replace either the

valve

or

guide

or

both,

as

necessary. Regrind the

seat

if

necessary,

to

make

it concentric with the

newly installed guide.

Loading...

Loading...