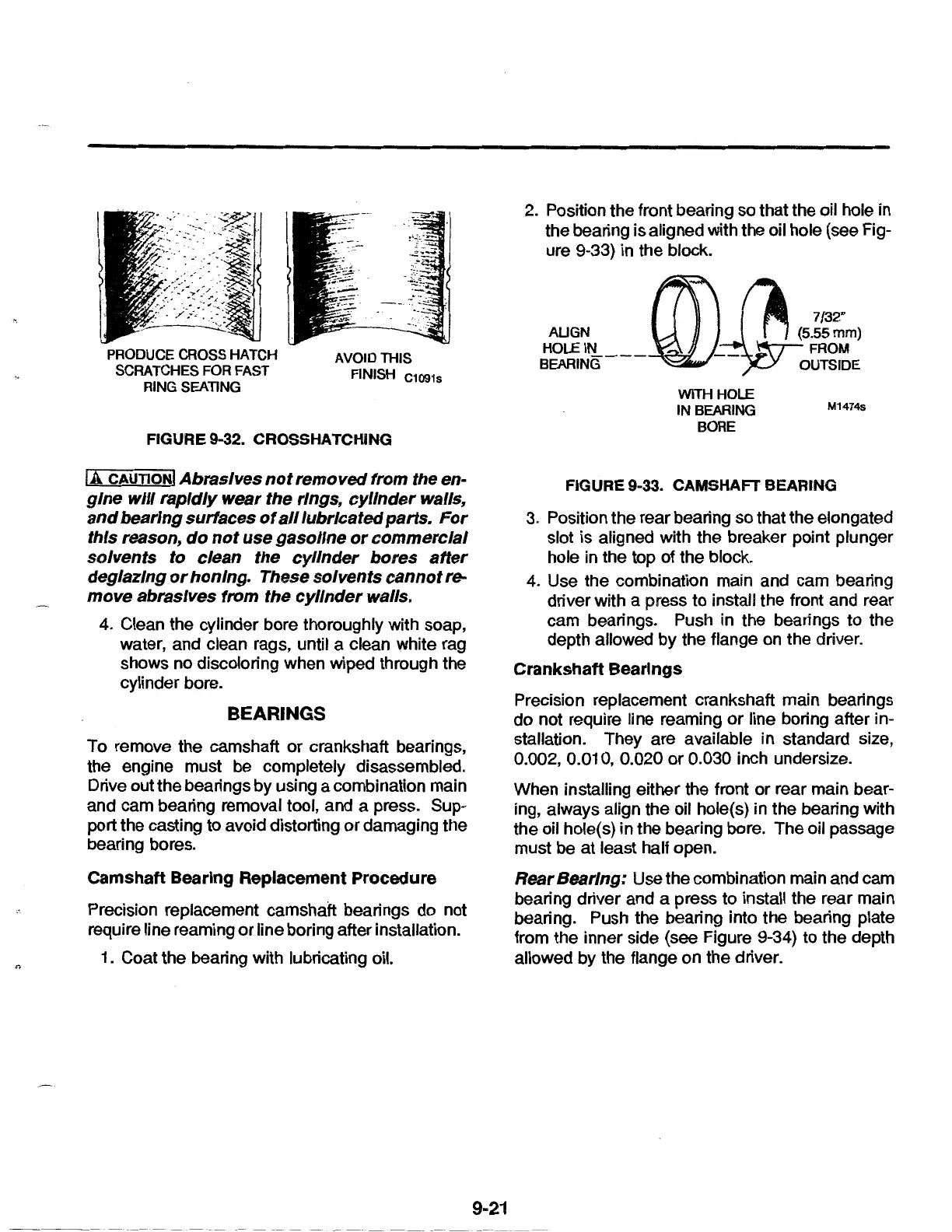

PRODUCE CROSS HATCH

SCRATCHES FOR FAST

RING SEATING

AVOID THIS

ANISH

C1091s

FIGURE 9-32. CROSSHATCHING

lA CAUTION! Abrasives

not

removed from the en-

gine

will

rapidly

wear the rings,

cylinder

walls,

and

bearing surfaces

of

all

lubricated parts.

For

this reason,

do

not

use

gasoline

or

commercial

solvents to clean the

cylinder

bores

after

deglazlng

or

honing. These solvents

cannot

re-

move

abrasives from the

cylinder

walls.

4. Clean the cylinder bore thoroughly with soap,

water, and clean rags, until a clean white rag

shows no discoloring when wiped through the

cylinder bore.

BEARINGS

To remove the camshaft or crankshaft bearings,

the engine must be completely disassembled.

Drive out the bearings by using a combination main

and cam bearing removal tool, and a press. Sup-

port the casting to avoid distorting

or

damaging the

bearing bores.

Camshaft

Bearing Replacement

Procedure

Precision replacement camshaft bearings do not

require line reaming

or

line boring after installation.

1 . Coat the bearing with lubricating oil.

9-21

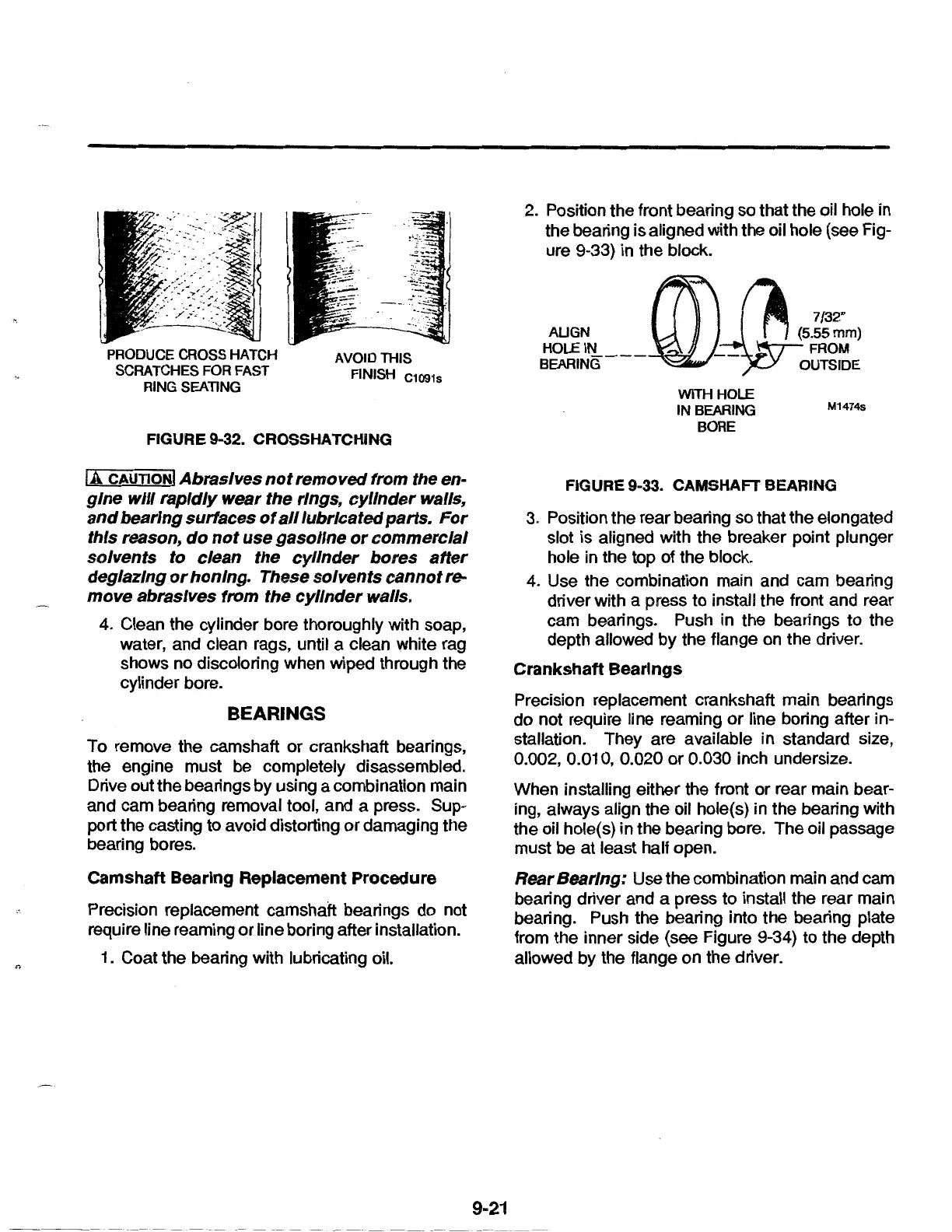

2. Position the front bearing so that the oil hole in

the bearing is aligned with the oil hole (see Fig-

ure 9-33} in the block.

AUGN

@

HOLE

If!.___

__

BEARING

WITH HOLE

IN BEARING

BORE

7/32"

(5.55

mm)

,____FROM

OUTSIDE

M1474s

FIGURE 9-33. CAMSHAFT BEARING

3.

Position the rear bearing so that the elongated

slot is aligned with the breaker point plunger

hole

in

the top of the block.

4.

Use the combination main and cam bearing

driver with a press to install the front and rear

cam bearings. Push in the bearings to the

depth allowed by the flange on the driver.

Crankshaft

Bearings

Precision replacement crankshaft main bearings

do not require line reaming or line boring after in-

stallation. They are available in standard size,

0.002,

0.01

0,

0.020

or

0.030 inch undersize.

When installing either the front or rear main bear-

ing, always align the oil hole(s) in the bearing with

the oil hole{s) in the bearing bore. The oil passage

must be at least half open.

Rear Bearing: Use the combination main and cam

bearing driver and a press to install the rear main

bearing. Push the bearing into the bearing plate

from the inner side (see Figure 9-34) to the depth

allowed by the flange on the driver.

Loading...

Loading...