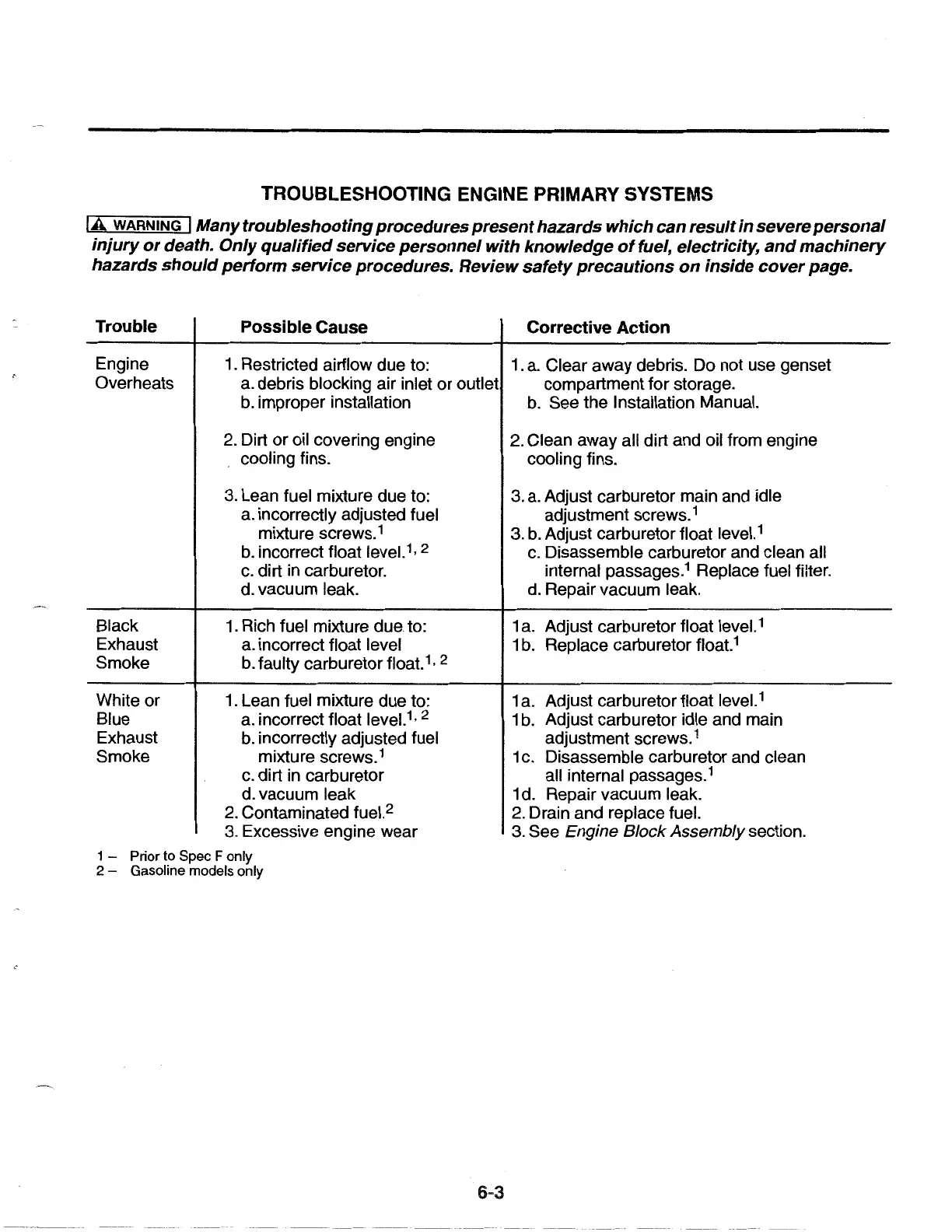

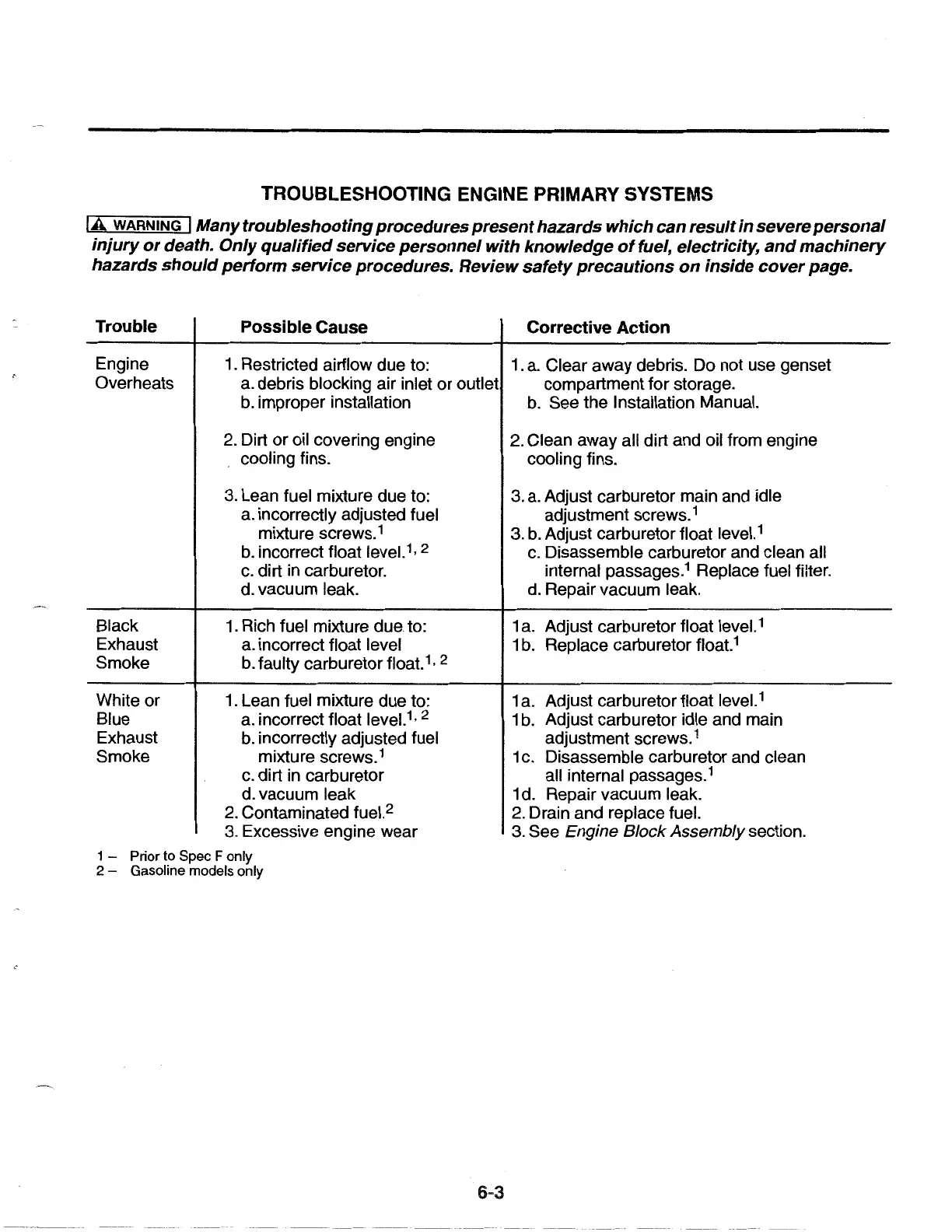

TROUBLESHOOTING ENGINE PRIMARY SYSTEMS

I

.A

WARNING I Many troubleshooting procedures

present

hazards which can

result

in

severe

personal

injury

or

death.

Only

qualified

service

personnel

with

knowledge

of

fuel, electricity,

and

machinery

hazards

should

perform

service procedures. Review

safety

precautions

on

inside

cover

page.

Trouble

Possible Cause

1.

Restricted airflow due to:

Engine

Overheats

a.

debris blocking air inlet

or

outlet

Black

Exhaust

Smoke

White or

Blue

Exhaust

Smoke

b.

improper installation

2. Dirt or oil covering engine

cooling fins.

3.

Lean fuel mixture due to:

a.

incorrectly adjusted fuel

mixture screws.1

b.

incorrect float level.

1.

2

c.

dirt in carburetor.

d. vacuum leak.

1.

Rich fuel mixture

due.

to:

a.

incorrect float level

b.

faulty carburetor float.1 · 2

1. Lean fuel mixture due to:

a.

incorrect float level. 1 • 2

b.

incorrectly adjusted fuel

mixture screws.1

c.

dirt

in

carburetor

d. vacuum leak

2. Contaminated fuel.2

3.

Excessive engine wear

1 - Prior to Spec F only

2 - Gasoline models only

6-3

Corrective Action

1.

a.

Clear away debris. Do not use genset

compartment for storage.

b.

See the Installation Manual.

2. Clean away all dirt and oil from engine

cooling fins.

3.

a.

Adjust carburetor main and idle

adjustment screws. 1

3.

b.

Adjust carburetor float level.

1

c.

Disassemble carburetor and clean all

internal passages.

1

Replace fuel filter.

d.

Repair vacuum leak.

1

a.

Adjust carburetor float level.

1

1

b.

Replace carburetor float.

1

1

a.

Adjust carburetor float level.

1

1

b.

Adjust carburetor idle and main

adjustment screws.1

1

c.

Disassemble carburetor and clean

all internal passages.

1

1 d. Repair vacuum leak.

2. Drain and replace fuel.

3.

See Engine Block Assembly section.

Loading...

Loading...