Reassembly:

1.

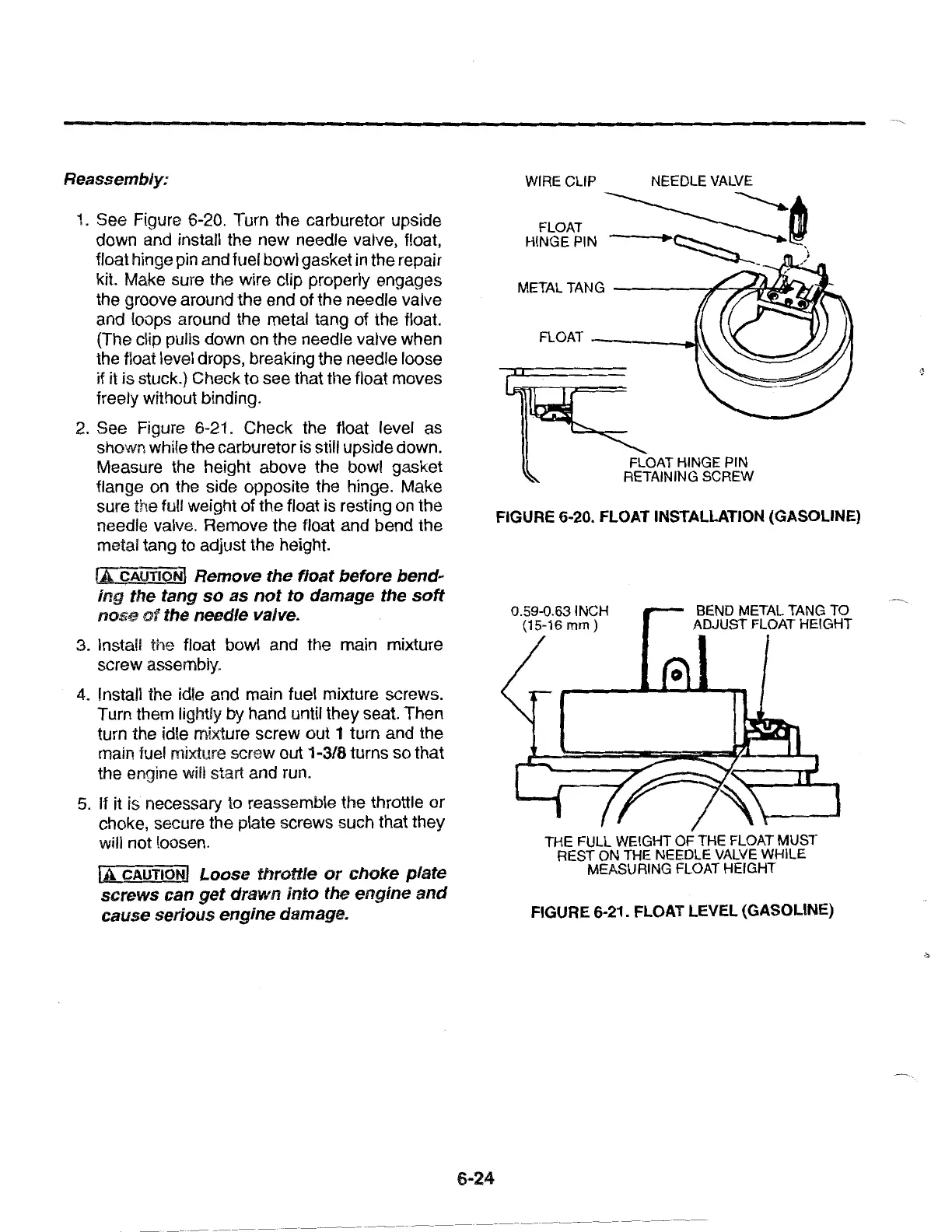

See Figure 6-20. Turn the carburetor upside

down and install the new needle valve, float,

float hinge pin and fuel bowl gasket in the repair

kit. Make sure the wire clip properly engages

the groove around the end of the needle valve

and loops around the metal tang

of

the float.

(The clip pulls down on the needle valve when

the float level drops, breaking the needle loose

if

it is stuck.) Check to see that the float moves

freely without binding.

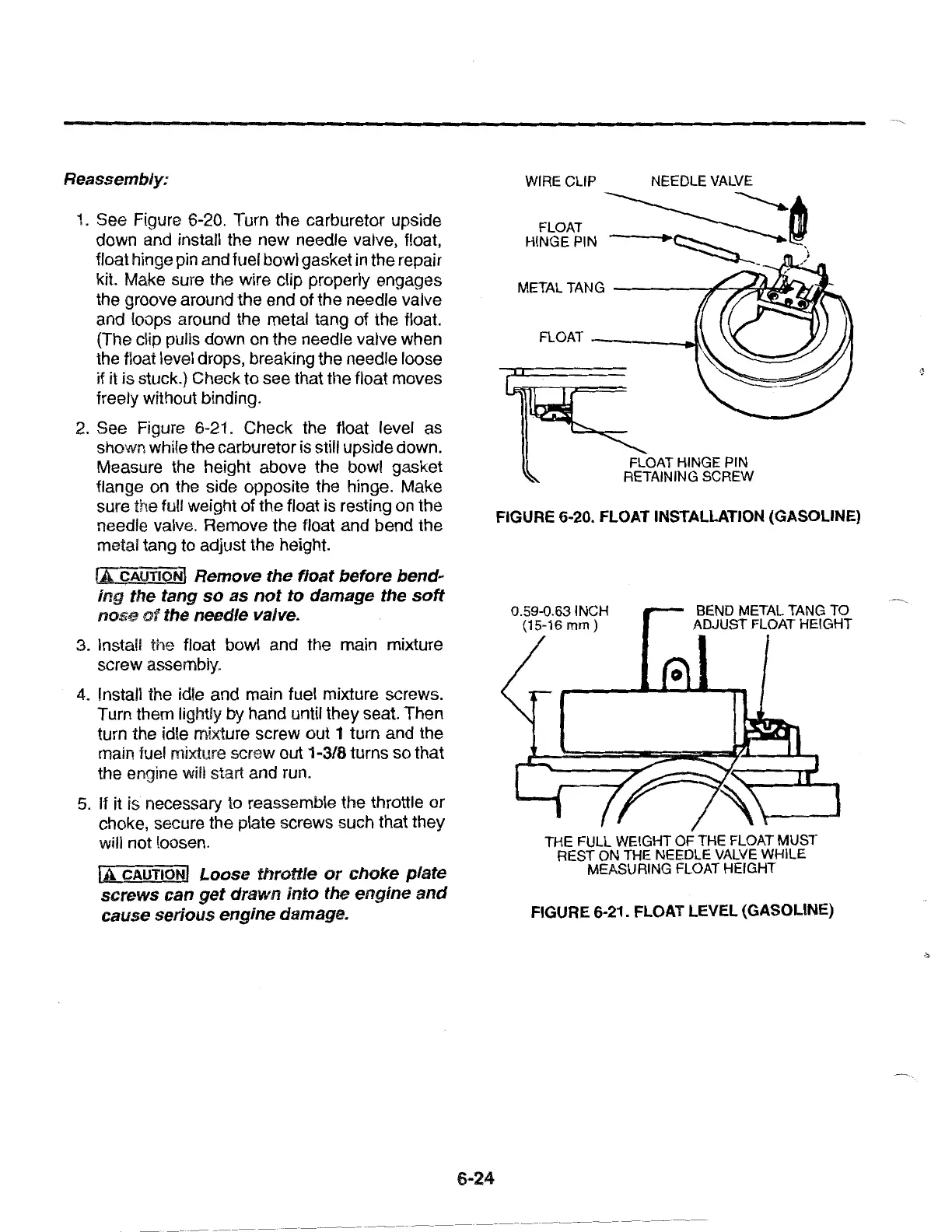

2. See Figure 6-21. Check the float level as

shown while the carburetor is still upside down.

Measure the height above the bowl gasket

flange on the side opposite the hinge. Make

sure the full weight of the float is resting on the

needle valve. Remove the float and bend the

metal tang

to

adjust the height.

lA CAUTION! Remove the float before bend-

ing

the tang

so

as

not

to

damage the

soft

nose

of

the needle valve.

3.

Install the float bowl and the main mixture

screw assembly.

4. Install the idle and main fuel mixture screws.

Turn them lightly by hand until they seat. Then

tum

the idle mixture screw out 1 turn and the

main fuel mixture screw out 1-3/8 turns so that

the engine will start and run.

5. If it is necessary

to

reassemble the throttle

or

choke, secure the plate screws such that they

will not loosen.

lA CAUTION! Loose

throttle

or

choke

plate

screws

can

get

drawn

into

the engine

and

cause serious engine damage.

6-24

WIRE CLIP

FLOAT

HINGE PIN

NEEDLE VALVE

-·~---~

FLOAT HINGE PIN

RETAINING SCREW

FIGURE 6-20. FLOAT INSTALLATION (GASOLINE)

0.59-0.63 INCH

(15-16

mm)

BEND METAL TANG TO

ADJUST FLOAT HEIGHT

THE FULL WEIGHT

OF

THE FLOAT MUST

REST ON THE NEEDLE VALVE WHILE

MEASURING FLOAT HEIGHT

FIGURE 6-21. FLOAT LEVEL (GASOLINE)

-------

-~-

----

----

--

---

------------

Loading...

Loading...