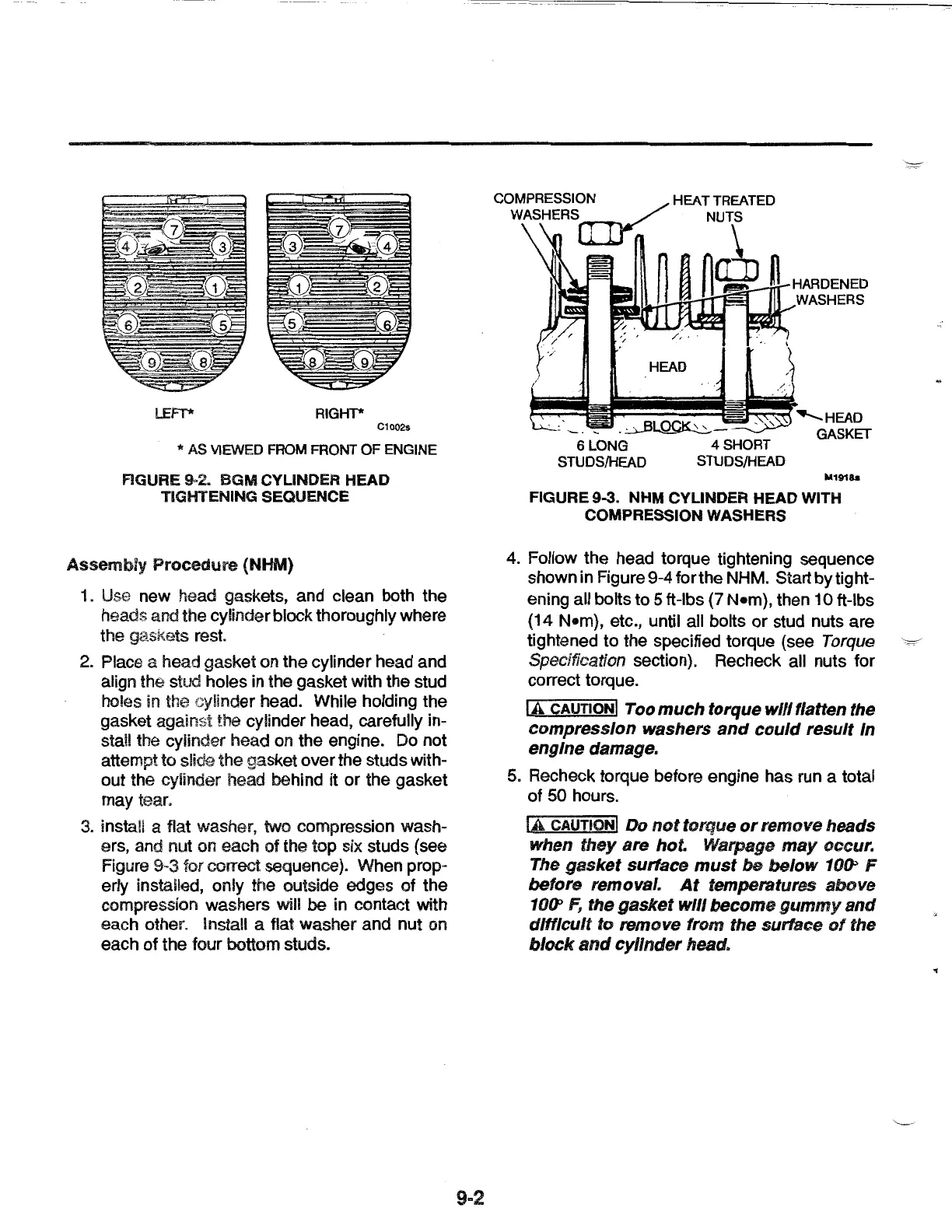

LEFT* RIGHT*

C1002s

*

AS

VIEWED

FROM

FRONT OF ENGINE

FIGURE

9~2.

BGM CYLINDER HEAD

TIGHTENING SEQUENCE

Assembly

Procedure (NHM)

1 . Use new head gaskets, and clean both the

heads and the cylinder block thoroughly where

the gaskets rest.

2.

Place a head gasket on the cylinder head and

align the stud holes in the gasket with the stud

holes in the cylinder head. While holding the

gasket against the cylinder head, carefully in-

stall the cylinder head on the engine. Do not

attempt

to

slide the gasket over the studs with-

out the cylinder head behind

it or the gasket

may tear.

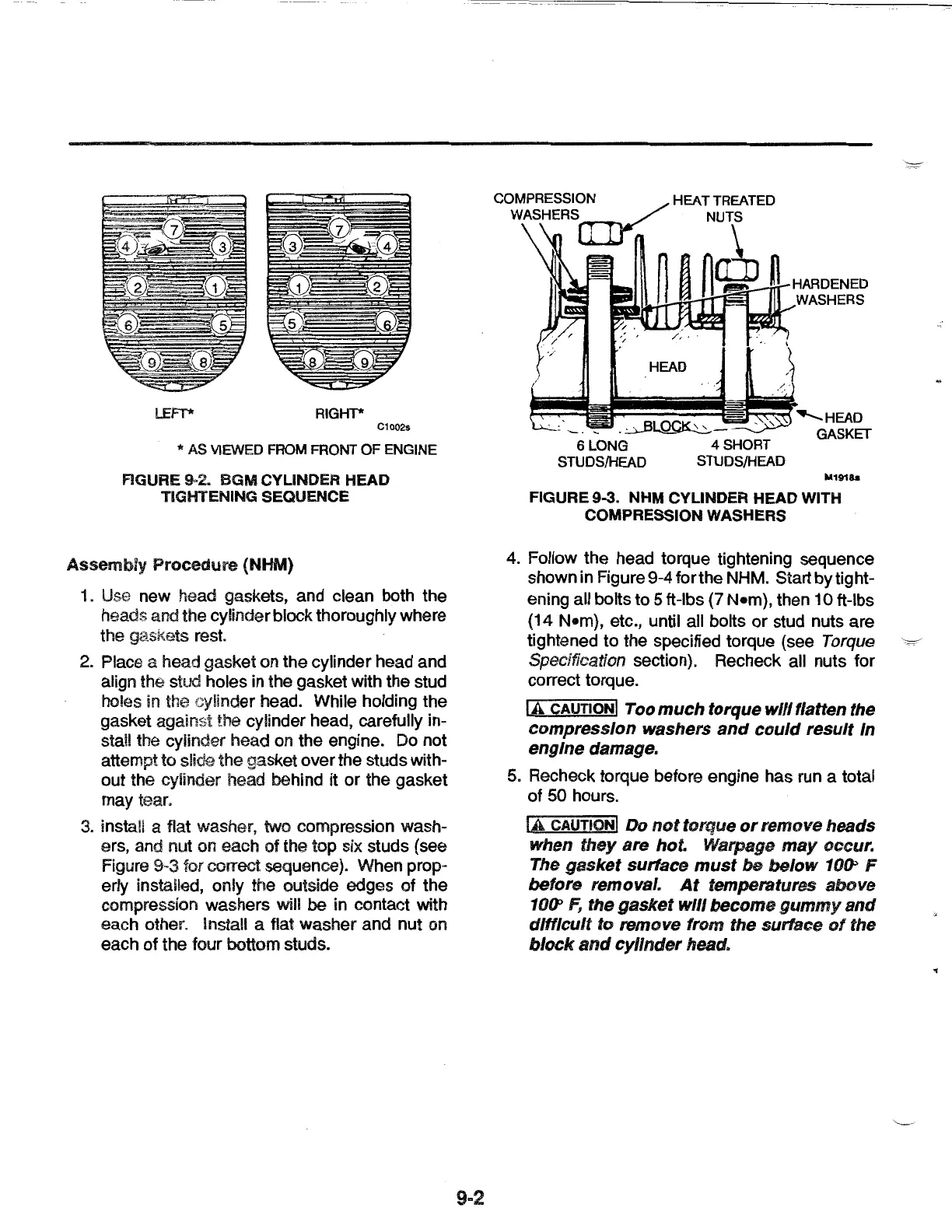

3. install a flat washer, two compression wash-

ers, and nut on each

of

the top six studs (see

Figure 9-3 for correct sequence). When prop-

erly installed, only the outside edges

of

the

compression washers will

be

in contact with

each other. Install a flat washer and nut on

each

of

the four bottom studs.

9-2

COMPRESS!~./

HEAT

TREATED

WASHERS

(llj

II NUTS

HEAD

-~~-

6 LONG 4 SHORT

STUDS/HEAD STUDS/HEAD

........._HEAD

GASKET

M191h

FIGURE 9-3. NHM CYLINDER HEAD WITH

COMPRESSION WASHERS

4. Follow the head torque tightening sequence

shown in Figure 9-4 for the NHM. Start

by

tight-

ening all bolts to

5 ft-lbs (7 N•m), then 10 ft-lbs

(14 N•m), etc., until all bolts

or

stud nuts are

tightened to the specified torque (see

Torque

·~

Specification section). Recheck all nuts for

correct torque.

lA CAUTION I

Too

much torque

will

flatten the

compression washers

and

could

result In

engine damage.

5. Recheck torque before engine has run a total

of

50 hours.

lA CAUTION! Do

not

torque

or

remove heads

when they are hot. Warpage

may

occur.

The gasket surface

must

be

below

10~

F

before removal.

At

temperatures above

10~

F,

the gasket

will

become

gummy

and

difficult

to remove from the surface

of

the

block

and

cylinder

head.

..

Loading...

Loading...