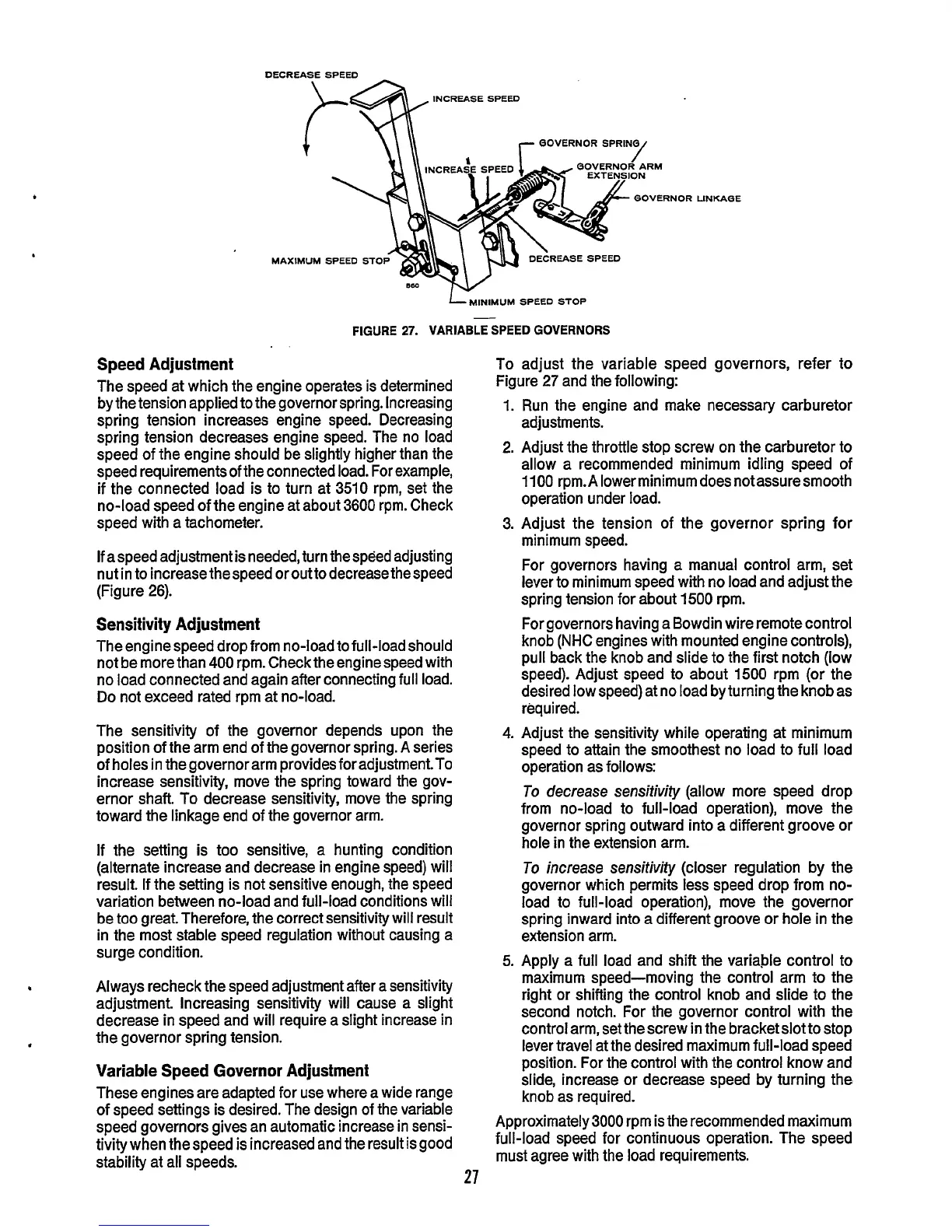

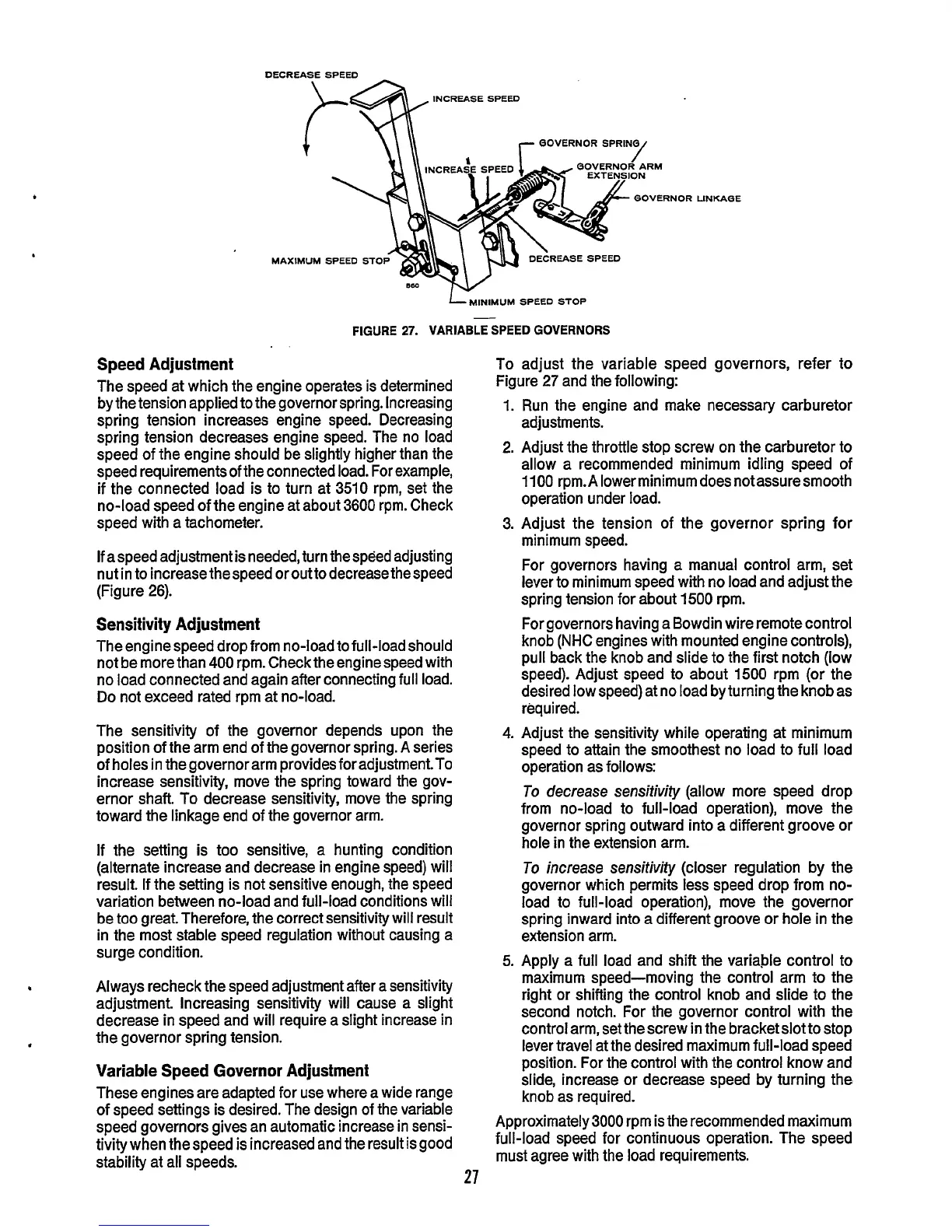

DECREASE SPEED

INCREASE SPEED

.

GOVERNO~

ARM

//

EXTENSION

t

MAXIMUM

DEGREASE

SPEED

SPEED STOP

$1

&GOVERNOR

L

MINIMUM SPEED

STOP

-

FIGURE

27.

VARIABLE

SPEED

GOVERNORS

Speed Adjustment

The speed at which the engine operates is determined

by the tension applied

to

the governor spring. Increasing

spring tension increases engine speed. Decreasing

spring tension decreases engine speed. The no load

speed of the engine should be slightly higher than the

speed requirements of the connected load. For example,

if the connected load is to turn at 3510 rpm, set the

no-load speed of the engine at about 3600 rpm. Check

speed with a tachometer.

If aspeed adjustment is needed, turn the speed adjusting

nut in to increasethespeed orouttodecreasethespeed

(Figure

26).

Sensitivity Adjustment

The engine speed drop from no-load

to full-load

should

not be more than

400

rpm. Check the engine speed with

no load connected and again after connecting full load.

Do not exceed rated rpm at no-load.

The sensitivity of the governor depends upon the

position of the arm end of the governor spring.

A

series

of holes in the governor arm provides foradjustment.To

increase sensitivity, move the spring toward the gov-

ernor shaft. To decrease sensitivity, move the spring

toward the linkage end of the governor arm.

If

the setting

is

too sensitive, a hunting condition

(alternate increase and decrease in engine speed) will

result. If the setting is not sensitive enough, the speed

variation between no-load and full-load conditions will

be too great Therefore, the correct sensitivity will result

in the most stable speed regulation without causing a

surge condition.

Always recheck the speed adjustment after a sensitivity

adjustment. Increasing sensitivity

will

cause a slight

decrease in speed and will require a slight increase in

the governor spring tension.

Variable Speed Governor Adjustment

These engines are adapted for use where a wide range

of speed settings is desired. The design of the variable

speed governors gives an automatic increase in sensi-

tivity when the speed is increased and the result is good

stability at all speeds.

27

I

JNKABE

To adjust the variable speed governors, refer to

Figure

27

and the following:

1.

2.

3.

4.

5.

Run the engine and make necessary carburetor

adjustments.

Adjust the throttle stop screw on the carburetor to

allow a recommended minimum idling speed of

1100 rpm.

A

lower minimum does not assure smooth

operation under load.

Adjust the tension of the governor spring for

minimum speed.

For governors having a manual control arm, set

lever to minimum speed with no load and adjust the

spring tension for about 1500 rpm.

For governors having a Bowdin wire remote control

knob

(NHC

engines with mounted engine controls),

pull back the knob and slide to the first notch (low

speed). Adjust speed to about

1500

rpm (or the

desired low speed) at no load by turning the knob as

required.

Adjust the sensitivity while operating at minimum

speed to attain the smoothest no load to full load

operation as follows:

To

decrease sensifivity (allow more speed drop

from no-load to full-load operation), move the

governor spring outward into a different groove or

hole in the extension arm.

To

increase sensitivity (closer regulation by the

governor which permits less speed drop from no-

load to full-load operation), move the governor

spring inward into a different groove or hole in the

extension arm.

Apply a full load and shift the variable control to

maximum speed-moving the control arm to the

right or shifting the control knob and slide to the

second notch. For the governor control with the

control arm, set the screw

in

the bracket slot to stop

lever travel at the desired maximum full-load speed

position. For the control with the control know and

slide, increase or decrease speed by turning the

knob as required.

Approximately3000 rpm is the recommended maximum

full-load speed for continuous operation. The speed

must agree with the load requirements.

Loading...

Loading...