.

Apply a thin film of oil to the gasket. Spin element

down by hand until gasket just touches mounting pad

and then turn down an additonalV4-1/2 turn.

Do

not

overtighten.

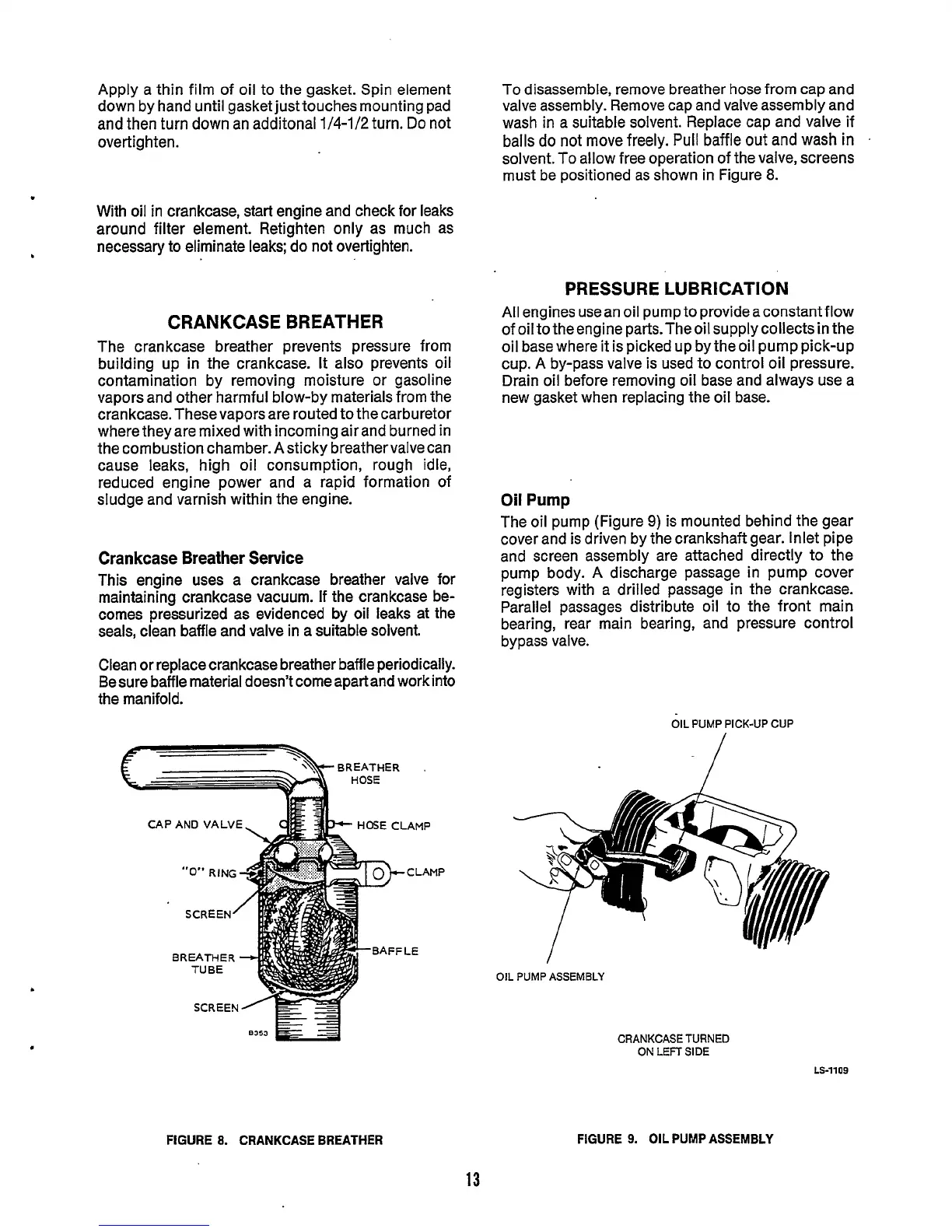

To

disassemble, remove breather hose from

cap

and

valve assembly. Remove cap and valve assembly and

wash in a suitable solvent. Replace cap and valve if

balls do not move freely.

Pull

baffle out and wash

in

solvent.

To

allow free operation of the valve, screens

must be positioned as shown in Figure

8.

With oil in crankcase, start engine and check for leaks

around filter element. Retighten only as much as

necessary to eliminate leaks; do not overtighten.

CRANKCASE BREATHER

The crankcase breather prevents pressure from

building up in the crankcase.

It

also prevents oil

contamination by removing moisture or gasoline

vapors and other harmful blow-by materials from the

crankcase. Thesevapors are routed to the carburetor

where they are mixed with incoming air and burned in

the combustion chamber. Asticky breathervalve can

cause leaks, high oil consumption, rough idle,

reduced engine power and a rapid formation of

sludge and varnish within the engine.

Crankcase Breather Service

This engine uses a crankcase breather valve for

maintaining crankcase vacuum. If the crankcase be-

comes pressurized as evidenced by oil leaks at the

seals, clean baffle and valve in a suitable solvent.

Clean or replace crankcase breather baff le periodically.

Besure baffle material doesn’t come apartand workinto

the manifold.

CAP

AND

VALVE

HOSE

CLAMP

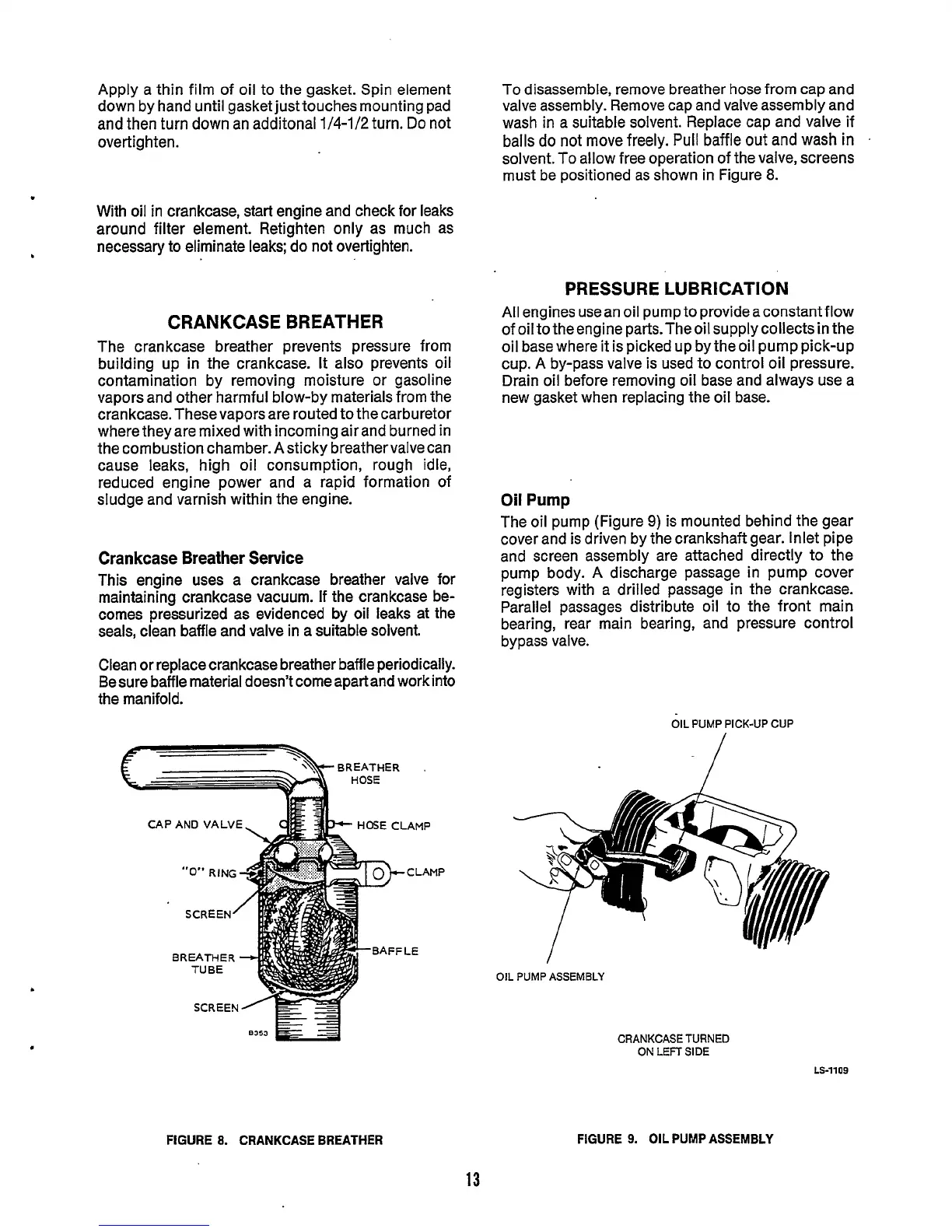

PRESSURE LUBRICATION

All engines usean oil pumpto provideaconstantflow

of oil to theengine parts.TheoiI supply collects in the

oil base where

it

is picked up by the oil pump pick-up

cup. A by-pass valve is used

to

control oil pressure.

Drain oil before removing oil base and always use a

new gasket when replacing the oil base.

Oil

Pump

The oil pump (Figure

9)

is mounted behind the gear

cover and

is

driven by the crankshaft gear. Inlet pipe

and screen assembly are attached directly to the

pump body. A discharge passage in pump cover

registers with a drilled passage in the crankcase.

Parallel passages distribute oil to the front main

bearing, rear main bearing, and pressure control

bypass valve.

OIL

PUMP

PICK-UP

CUP

OIL

PUMP

ASSEMBLY

CRANKCASETURNED

ON

LEFT

SIDE

FIGURE

8.

CRANKCASE BREATHER

FIGURE

9.

OIL

PUMP

ASSEMBLY

13

Loading...

Loading...