4

WHEN GOVERNOR

IS

PROPERLY

ASSEMBLED

THE

DIMENSION

SHOWN

ON

DRAWING

WILL

BE

AS

INDICATED

CENTER

PIN

,

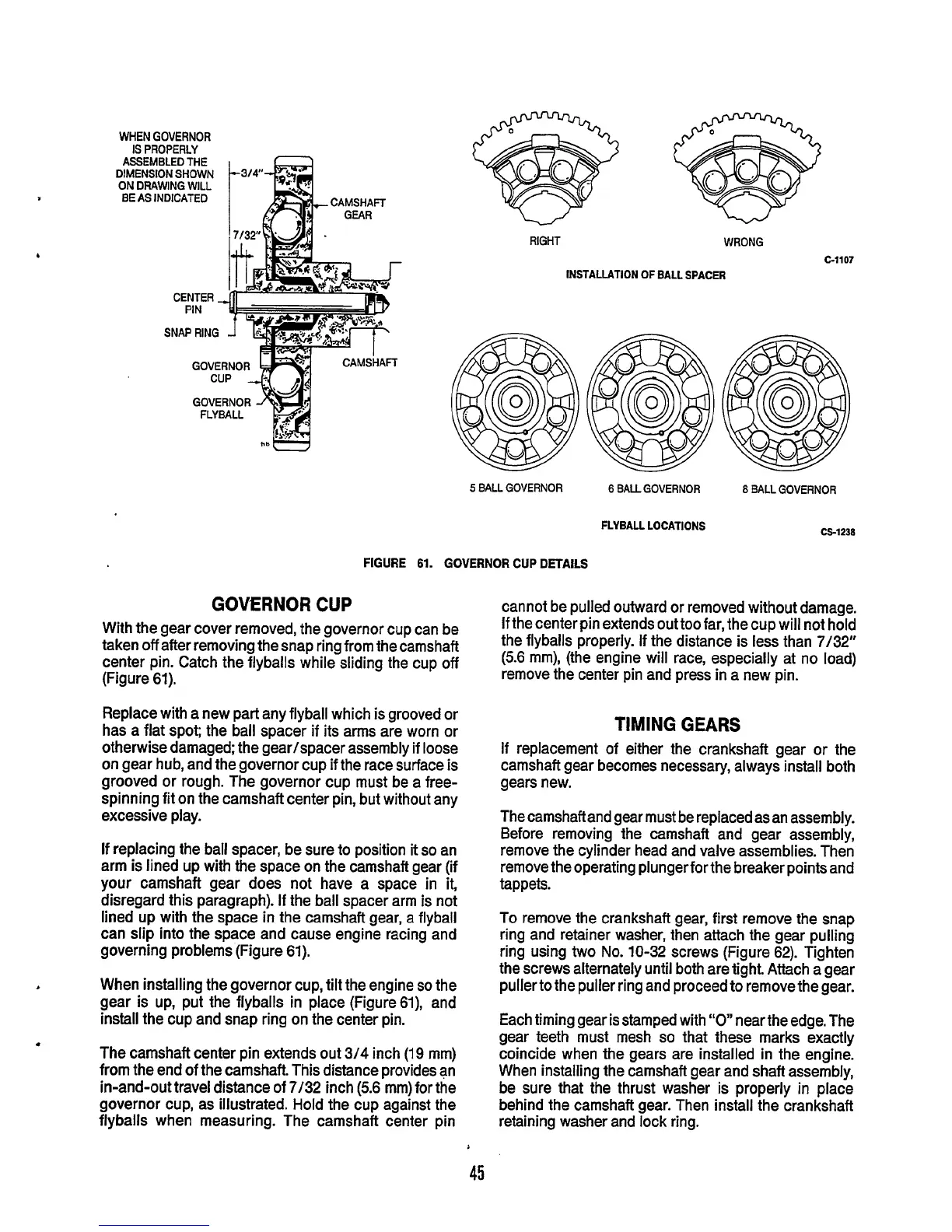

RIGHT

WRONG

INSTALLATION

OF

BALL

SPACER

G1107

5

BALL

GOVERNOR

6

BALL

GOVERNOR

8

BALL

GOVERNOR

SI238

FLYBALL LOCATIONS

FIGURE

61.

GOVERNOR

CUP

DETAILS

GOVERNOR

CUP

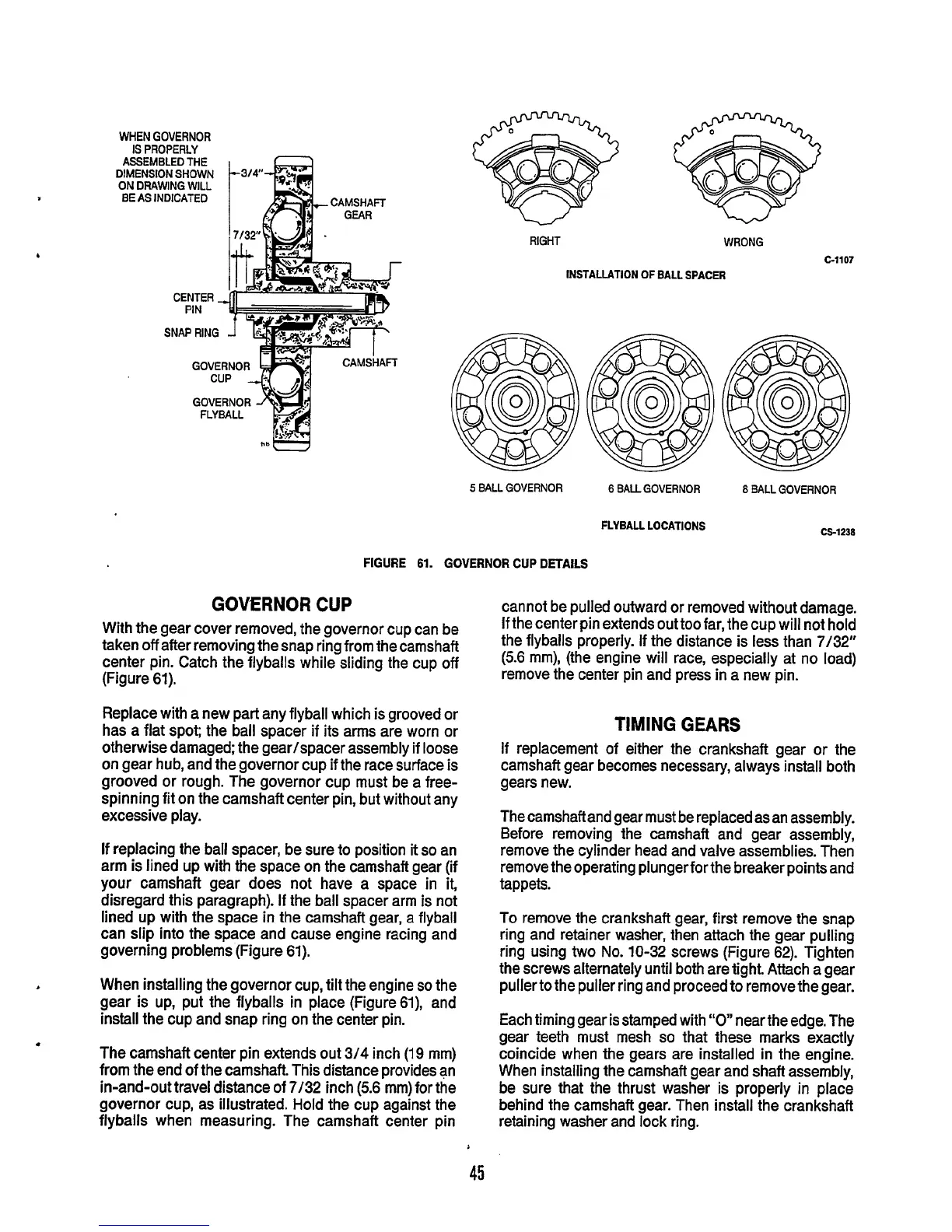

With the gear cover removed, the governor cup can be

taken

off

after removing the snap ring from the camshaft

center pin. Catch the flyballs while sliding the cup

off

(Figure 61).

Replace with a new part any flyball which is grooved or

has a flat spot; the ball spacer if its arms are worn or

otherwise damaged; the gearispacer assembly if loose

on gear hub, and the governor cup if the race surface is

grooved or rough. The governor cup must be

a

free-

spinning fit on the camshaft center pin, but without any

excessive play.

If replacing the ball spacer, be sure to position

it

so

an

arm

is

lined up with the space on the camshaft gear (if

your camshaft gear does not have a space in it,

disregard this paragraph). If the ball spacer arm is not

lined up with the space in the camshaft gear,

a

flyball

can slip into the space and cause engine racing and

governing problems (Figure

61).

When installing the governor cup, tilt the engine

so

the

gear is up, put the flyballs in place (Figure61), and

install the cup and snap ring on the center pin.

The camshaft center pin extends out

3/4

inch

(19

mm)

from the end of the camshaft. This distance provides an

in-and-out travel distance of 7/32 inch

(5.6

mm) for the

governor cup, as illustrated. Hold the cup against the

flyballs when measuring. The camshaft center pin

cannot be pulled outward or removed without damage.

If the center pin extends out too far, the cup will not hold

the flyballs properly. If the distance is less than 7/32“

(5.6 mrn), (the engine will race, especially at no load)

remove the center pin and press in a new pin.

TIMING

GEARS

If replacement of either the crankshaft gear or the

camshaft gear becomes necessary, always install both

gears new.

The camshaft and gear must be replaced as an assembly.

Before removing the camshaft and gear assembly,

remove the cylinder head and valve assemblies. Then

remove the operating plunger for the breaker points and

tappets.

To

remove the crankshaft gear, first remove the snap

ring and retainer washer, then attach the gear pulling

ring using

two

No.

10-32 screws (Figure 62). Tighten

the screws alternately until both are tight. Attach a gear

puller to the puller ring and proceed to remove the gear.

Each timing gear is stamped with

“0

near the edge. The

gear teeth must mesh

so

that these marks exactly

coincide when the gears are installed in the engine.

When installing the camshaft gear and shaft assembly,

be sure that the thrust washer

is

properly in place

behind the camshaft gear. Then install the crankshaft

retaining washer and lock ring.

45

Loading...

Loading...