The safety screen used to cover

1

vents must be IN-inch

(6.35

mm)

mesh,

or

larger,

to

permit sufficient air flow and must

be commensurate

with

safefy standards for hazard-

ous

moving parts to avoid personal contact. Provide a

short canvas section between the engine air outlet

and the external duct or opening to absorb vibration.

If operation

in

cold weatheris likely, installing a shut-

ter

in

the air outlet is advisable. Cold weather can

cause overcooling if air flow is

not

regulafed.

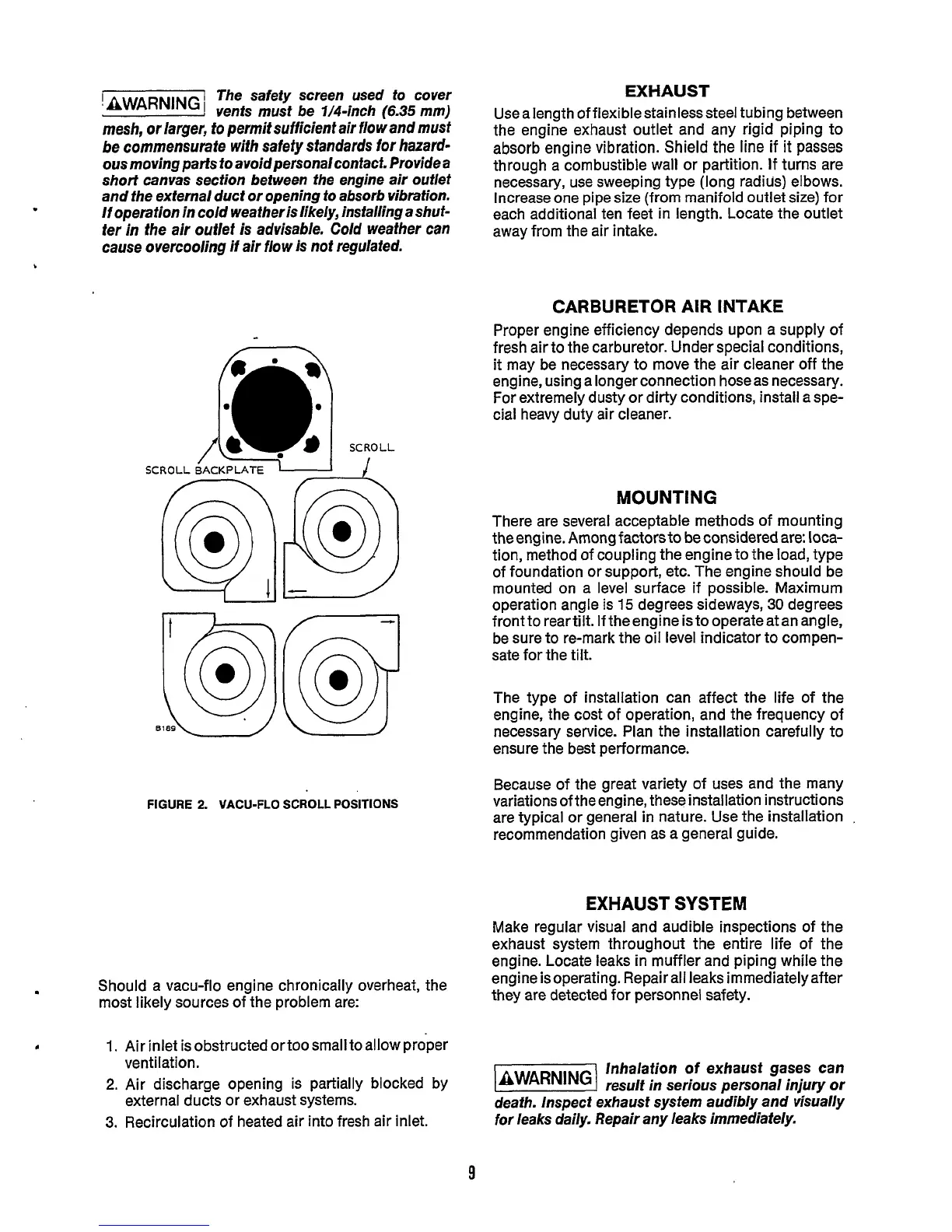

SCROLL

BACKPLATE

mi@

FIGURE

2.

VACU-FLO

SCROLL

POSITIONS

EXHAUST

Usea length

offlexiblestainlesssteel

tubing between

the engine exhaust outlet and any rigid piping to

absorb engine vibration. Shield the

line

if

it

passes

through a combustible wall or partition. If turns are

necessary, use sweeping type (long radius) elbows.

Increase one pipe size (from manifold outlet size) for

each additional ten feet in length. Locate the outlet

away from the air intake.

CARBURETOR

AIR

INTAKE

Proper engine efficiency depends upon a supply of

fresh air to the carburetor. Under special conditions,

it may be necessary to move the air cleaner off the

engine, using a longer connection hoseas necessary.

For extremely dusty or dirty conditions, install a spe-

cial heavy duty air cleaner.

MOUNTING

There are several acceptable methods of mounting

the engine. Among factors to be considered are: loca-

tion, method of coupling the engine to the load, type

of foundation or support, etc. The engine should be

mounted on a level surface if possible. Maximum

operation angle is

15

degrees sideways,

30

degrees

frontto reartilt. Iftheengineistooperateatanangle,

be sure to re-mark the oil level indicator to compen-

sate for the tilt.

The type of installation can affect the life of the

engine, the cost of operation, and the frequency of

necessary service. Plan the installation carefully to

ensure the best performance.

Because

of

the great variety of uses and the many

variations of the engine, these installation instructions

are typical

or

general in nature. Use the installation

recommendation given as a general guide.

EXHAUST

SYSTEM

Make regular visual and audible inspections of the

exhaust system throughout the entire life of the

engine. Locate leaks in muffler and piping while the

engine is operating. Repair all leaks immediately after

they are detected for personnel safety.

Should a vacu-flo engine chronically overheat, the

most likely sources of the problem are:

1,

Air inlet is obstructed or too small to allow proper

2.

Air discharge opening is partially blocked by

3.

Recirculation of heated air into fresh air inlet.

Inhalation

of

exhaust

gases

can

7)

result in serious persona/ jnjuv

or

death. Inspect exhaust system audibly and visually

for leaks daily. Repair any leaks immediately.

ventilation.

external ducts or exhaust systems.

9

Loading...

Loading...