CONNECTING

THE

LOAD

The dimensions of various power takeoff shafts are as

follows:

~~

SHAFT

STD

DIAMETER LENGTH

KEY SIZE

1-711 6 3-1/16 318

(36.51

mml

(77.78

mml

(9.5

mm)

Rockford

Clutch

Gear

Reduction

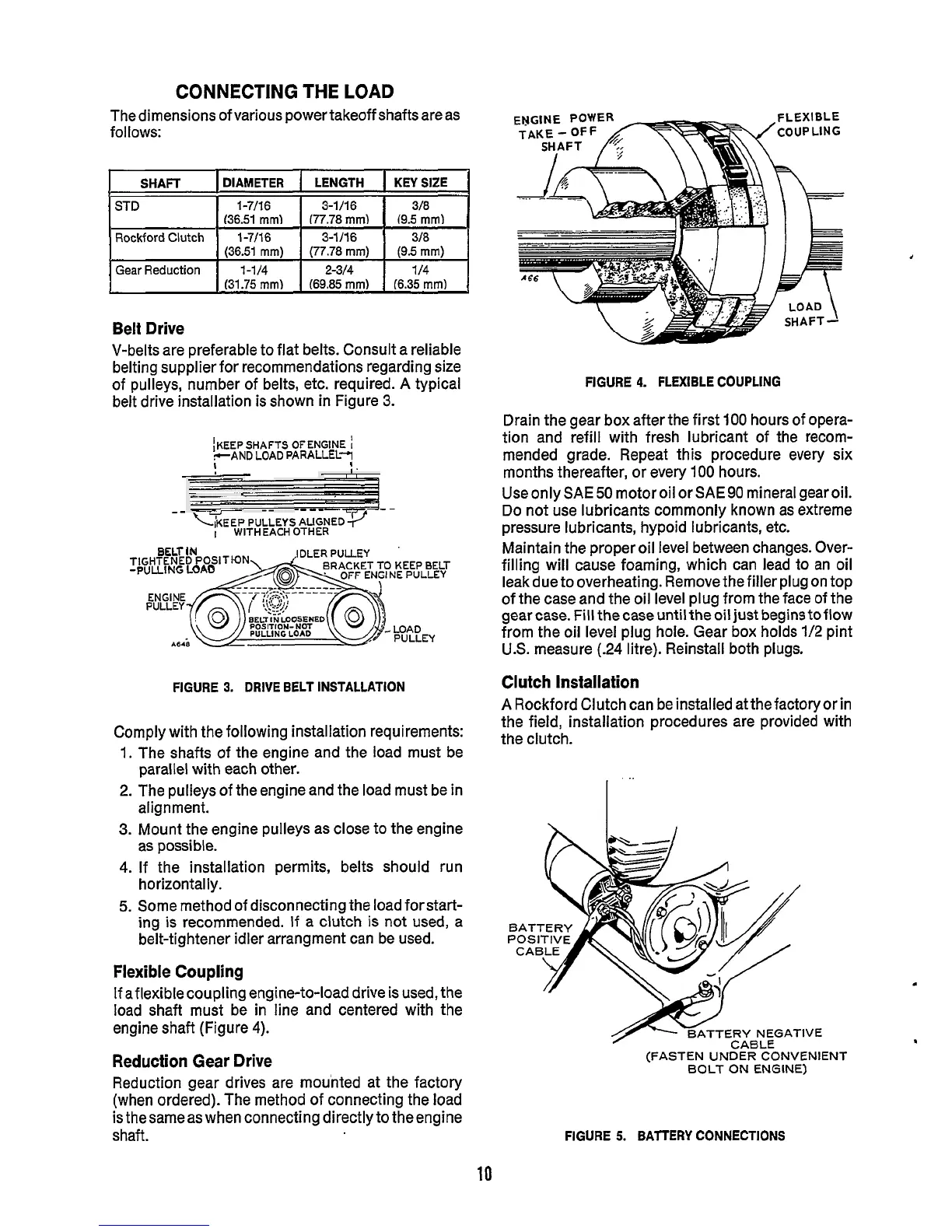

Belt Drive

V-belts are preferable to flat belts. Consult a reliable

belting supplier for recommendations regarding size

of pulleys, number

of

belts, etc. required.

A

typical

belt drive installation

is

shown in Figure

3.

1-7/16 3-1/16 318

(36.51

mm)

(77.78

mm)

(9.5

mm)

1-114 2-314

1

I4

(31.75

mm)

(69.85

mm)

(6.35

mm)

~KEEPSHAFTS

OFENGINE

I

?AND LOAD PARALLEL?

I

I

I

.

..

---

_-

BELT

IN

-PULLING LOAD

FIGURE

3.

DRIVE BELT INSTALLATION

Comply with the following installation requirements:

1.

2.

3.

4.

5.

The shafts of the engine and the load must be

parallel with each other.

The pulleys

of

the engine and the load must be in

alignment.

Mount the engine pulleys as close

to

the engine

as possible.

If the installation permits, belts should run

horizontally.

Some method of disconnecting the load forstart-

ing is recommended. If a clutch

is

not used, a

belt-tightener idler arrangment can be used.

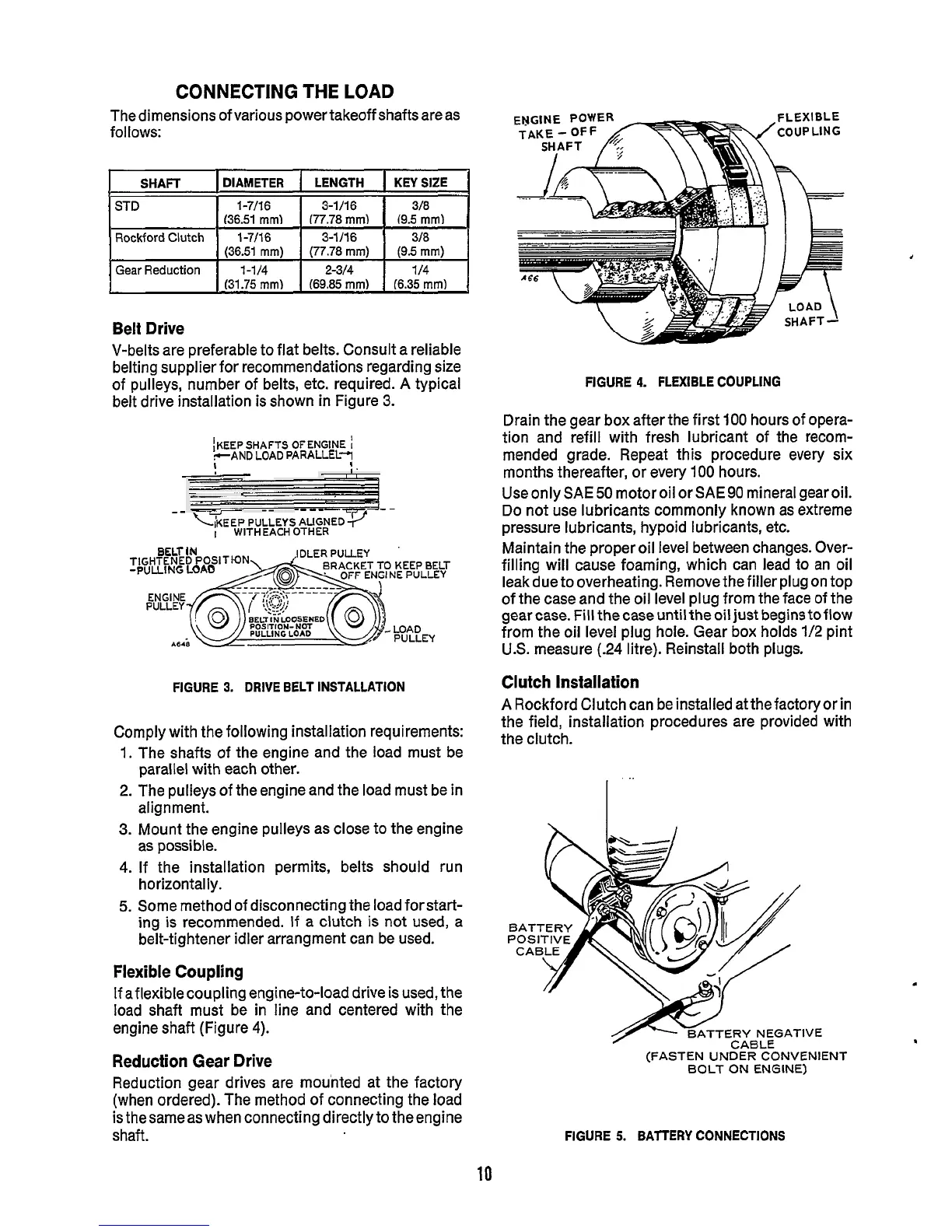

Flexible Coupling

If aflexiblecoupling engine-to-load drive is used, the

load shaft must be in line and centered with the

engine shaft (Figure

4).

Reduction Gear

Drive

Reduction gear drives are mounted at the factory

(when ordered). The method of connecting the load

is

thesameaswhen connecting directlyto theengine

shaft.

I

I

wf

SHAFT-

LOAD

\

FIGURE

4.

FLEXIBLE COUPLING

Drain the gear box after the first

100

hours of opera-

tion and refill with fresh lubricant of the recom-

mended grade. Repeat this procedure every six

months thereafter, or every

100

hours.

Use only

SAE

50

motor oil or

SAE

90

mineral gear oil.

Do not use lubricants commonly known as extreme

pressure lubricants, hypoid lubricants, etc.

Maintain the proper oil level between changes. Over-

filling will cause foaming, which can lead to an

oil

leak due to overheating. Remove the filler plug on top

of the case and the oil level plug from the face of the

gearcase. Fill thecaseuntiltheoil just beginstoflow

from the oil level plug hole. Gear box holds

1/2

pint

U.S.

measure

(.24

litre). Reinstall both plugs.

Clutch Installation

A

Rockford Clutch can be installed atthe factory or in

the field, installation procedures are provided with

the clutch.

(FASTEN

UNDER

CONVENIENT

BOLT

ON

ENGINE)

FIGURE

5.

BATTERY CONNECTIONS

,

10

Loading...

Loading...