Owner’s Manual for ONICON Insertion Turbine Flow Meters • September 27, 2001

11

When you are ready to refill the system, make sure that all lines are filled with

water before inserting the turbine into the stream. If the lines are not filled, air may

interrupt the flowing stream and damage the turbine assembly. A greater danger is

that if this is a hot water system, some water may flash into steam and exceed the

high temperature limit for the turbine and its mechanical assembly. This flash over

could exceed the pressure ratings of the meter and the assembly could fail allowing

steam and hot water to escape causing serious injury.

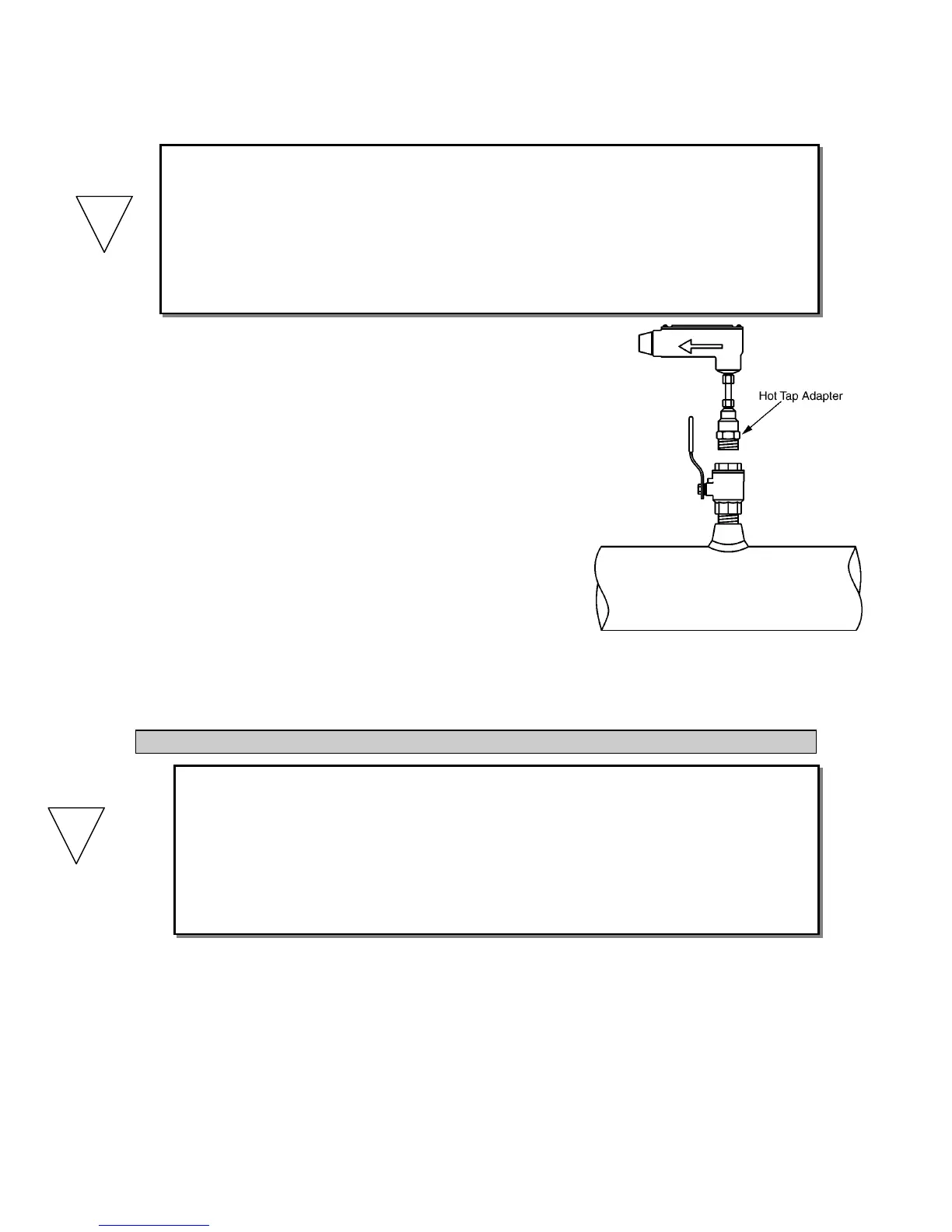

After fitting the necessary plumbing hardware, flush the

entire system so that it is free of flux, solder and slag. Prepare

to install the flow meter by loosening the clamping nut and

withdrawing the turbine assembly fully into the hot tap

adapter. Next, thread the adapter on to the ball valve using a

paste type thread sealant. Do not use Teflon tape because

torn strands of the tape may wind around the turbine,

slowing down or even stopping the turbine.

Check the installation for leaks by slightly opening the ball

valve under the hot tap adapter. An ‘O’ ring in the adapter

seals the meter stem against leakage. If there are any leaks

around the clamping nut or stem, DO NOT ATTEMPT TO

STOP THE LEAKAGE BY OVERTIGHTENING THE

CLAMPING NUT. Damage to this nut or the clamping ring

under the nut may prevent the assembly from properly holding the meter in the pipe. The

clamping nut is not part of the sealing mechanism. Any leaks in this area indicate that the ‘O’

ring is not sealing properly and you must contact the factory for assistance.

3.3 INSERTION OF THE METER

***CAUTION***

SYSTEM MAY BE UNDER HIGH PRESSURE. When adjusting the meter position or

removing it, be sure to hold the electronics enclosure firmly by hand before

SLOWLY loosening the positioning clamping nut. Failure to do this will allow the

pressure to suddenly and rapidly force the meter from the pipe causing serious

injury. The meter could also be damaged or break apart causing a break in the water

seal with the resultant loss of large amounts of water. The hand effort required to

hold the meter will be 0.11 times the pipe pressure.

Begin by calculating the effort that will be required to hold the meter. Establish adequate

footing for this task, taking extra caution when working from a ladder or platform. Use the

following formula:

E=0.11xP Where: E = effort in pounds

P = system pressure in pounds per square inch

Example: In a 300 PSI system, 33 pounds of effort is required to insert the meter into the pipe.

!

!

Loading...

Loading...