Owner’s Manual for ONICON Insertion Turbine Flow Meters • September 27, 2001

5

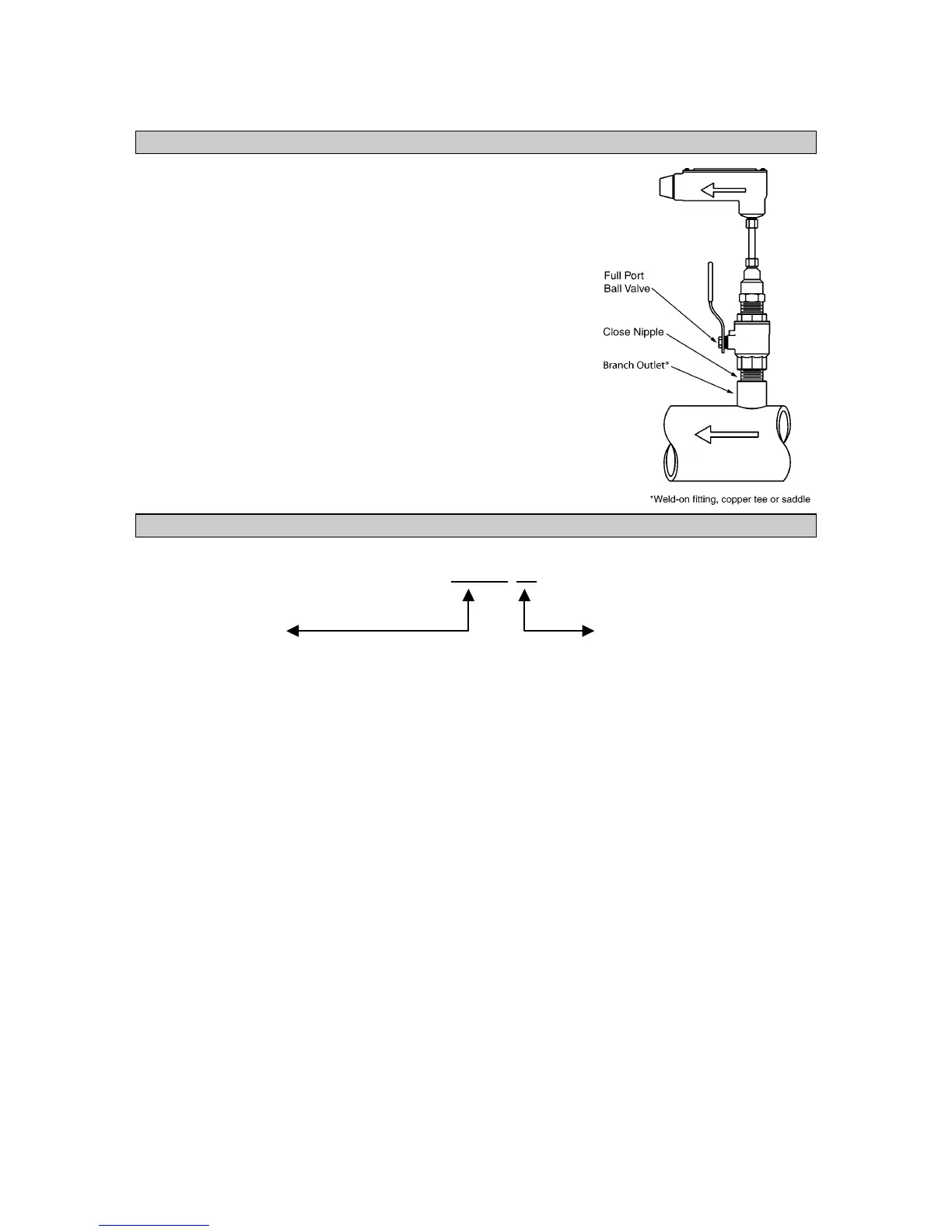

1.4 INSTALLATION HARDWARE

All ONICON insertion type meters can be installed and

removed via a 1” or larger full port ball valve without system

shutdown. The terms “Standard” and “Hot Tap” refer to the

installation method of the isolation valve kit only.

Standard Installation Hardware: For new construction or

scheduled shutdown. Once kit is installed, the flow meter can

be installed or removed without system shutdown.

Hot Tap Installation Hardware: For applications which

require the access hole in the pipe to be drilled through the

valve using a wet tap drilling machine, while the hydronic

system is pressurized and operating.

1.5 MODEL NUMBERING SYSTEM

F(B)-XX

YY

SERIES OUTPUT SIGNAL

F-11 Single Turbine, Insertion Type

F-12 Dual Turbine, Insertion Type

FB-12 Bi-Directional, Insertion Type

F-13 Inline Turbine Meter

Example: “F-1210” = Dual turbine, analog output

00 Frequency Output (15 V pulse)

For connection to Onicon display or BTU

meter only. Signal is too fast for most

building control systems (0-300 hz).

10 Analog Output (non-isolated)

Provides both 4-20 mA and 0-10 V

outputs. Most commonly used output

type. (3-wire connection)

11 Isolated Analog Output

Provides both 4-20 mA and 0-10 V

outputs. Signal ground is isolated from

power supply and pipe ground. (4-wire

connection)

20 Divided Output

(Solid state dry contact)

Provides an isolated binary/digital output.

Signal is divided to limit the maximum

frequency. For rate/totalization.

30 Scaled Output

(Solid state dry contact)

Provides an isolated binary/digital output

scaled to provide one pulse per desired

unit volume (i.e.: 1 pulse = 10 gal.).

Ideal for totalization applications.

Loading...

Loading...