Page 16

12.10.12 Issue 1

10.0 Troubleshooting

10.1 Print Quality Problems

Print Pads

Factory supplied print pads are 45-50° shore hardness rubber bonded to an aluminium backing sheet

and ground flat. Pads will become uneven with use and this will affect print quality as will any

imperfections.

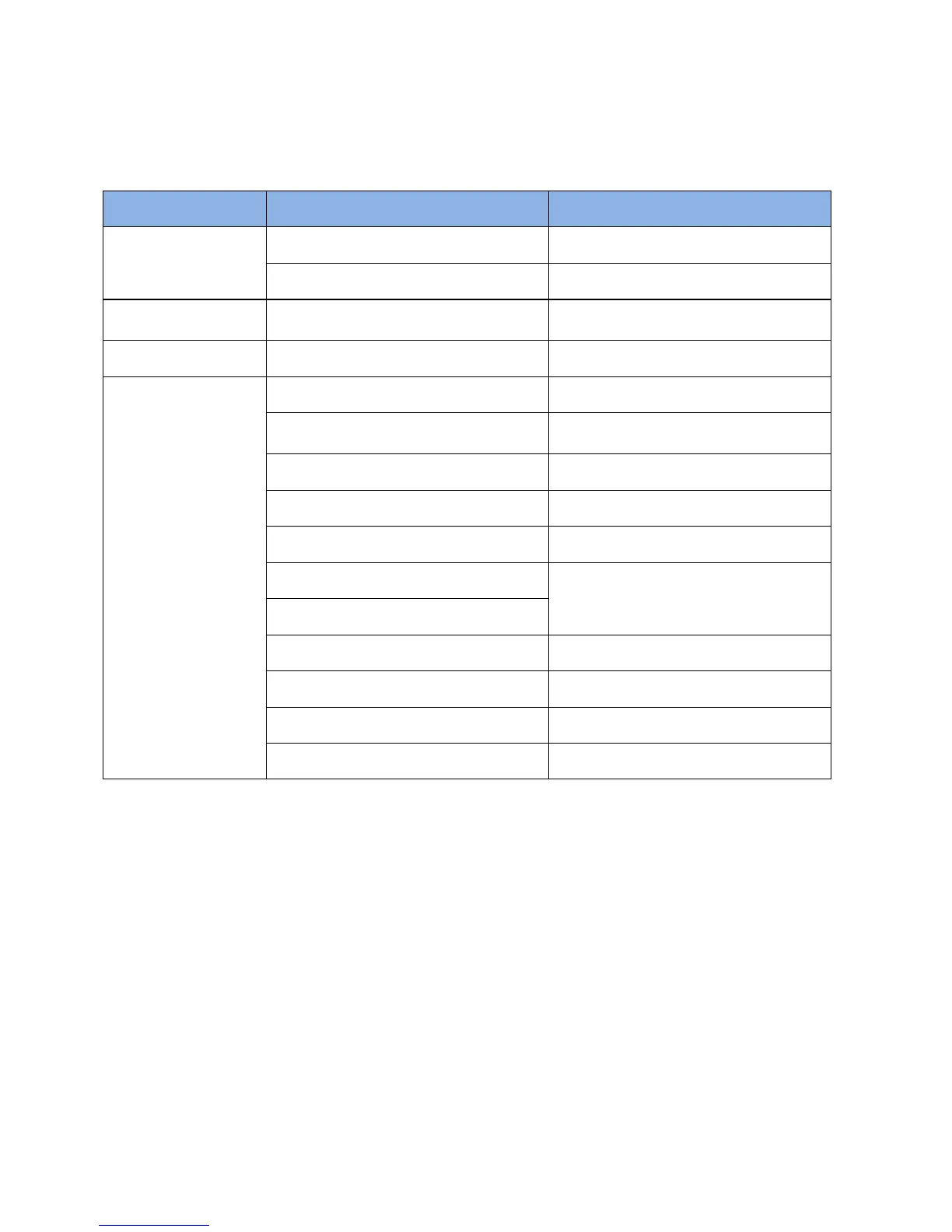

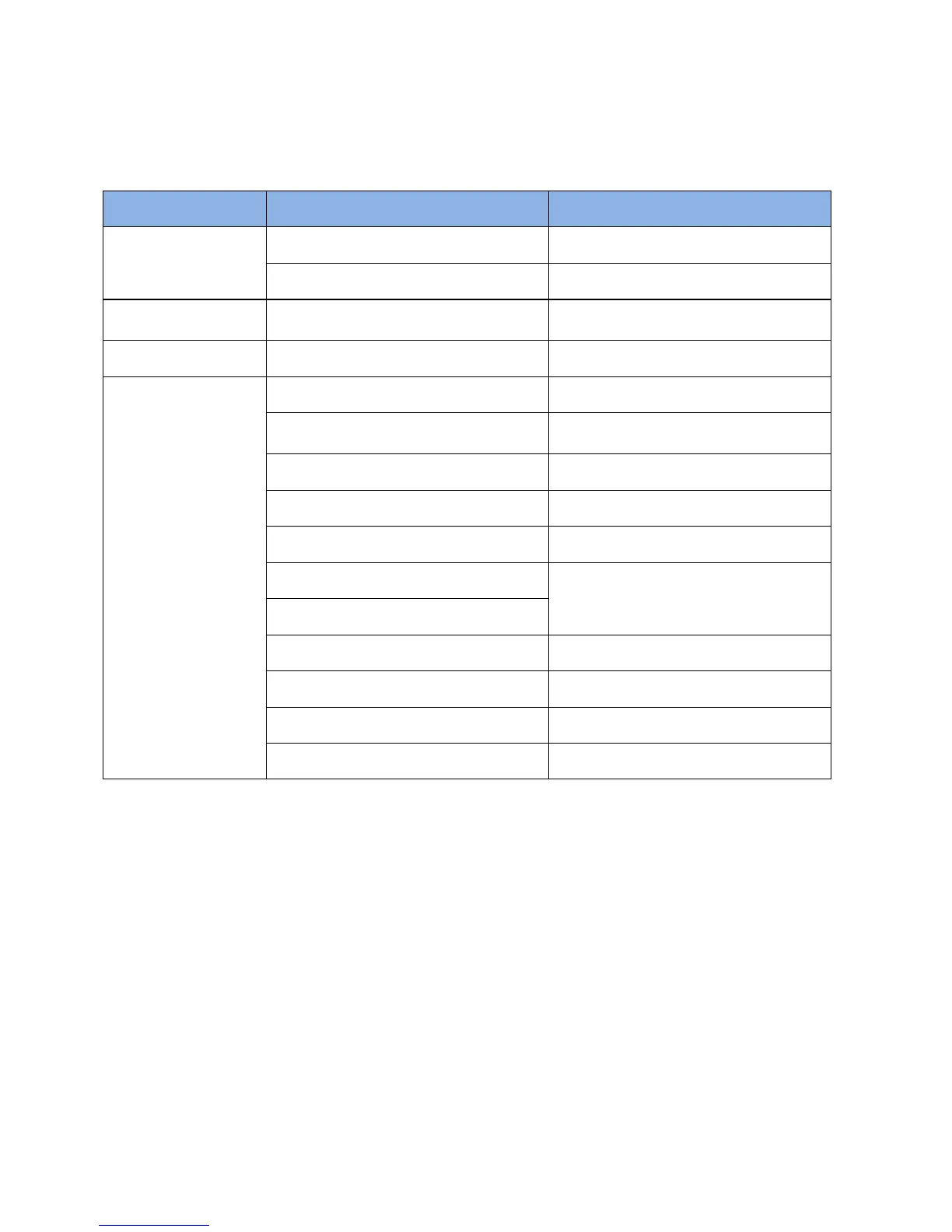

Problem Possible Cause Solution

Lines and or streaks

Incorrect ribbon tension Adjust ribbon brake on magazine

Printhead angle (roll & pitch)

Adjust printhead to be level with print pad and to its

correct angle

Print quality gradually

lightens

Loss of vertical position / profile not correct for ap-

plication.

Recalibrate printer by removing and replacing the

magazine

No print output although

printhead scans

Check printhead resistance code (see software

manual)

Check printhead resistance code. Generate new

code for same resistance

Print not consistent over

printed area?

Ribbon not compatible with substrate. Try alternative ribbon for purpose.

Temperature burn, settings too low.

Increase burn. (Low printing temperatures can give

the effect of the edges of characters appearing faint

or ragged)

Damaged or dirty print base.

Clean and check for any imperfections. Replace if

necessary. (see note below)

Printer not correctly mounted in frame. Check and adjust if necessary

Printer frame not manufactured to correct dimen-

sions, clearance under printer excessive.

See Standard Frame measurements drawings at

the end of this manual.

Printhead dirty.

Clean the printhead and test print on plain fax pa-

per to confirm the condition of the printhead.

Printhead pixels burnt out.

Ribbon indexing not enough. See previous page.

Ribbon tracking on printer, causing creasing. See previous page.

Ribbon perforated or broken. See previous page.

Ribbon ink coating inconsistent. Return ribbon to supplier for testing

Loading...

Loading...