Page 17

12.10.12 Issue 1

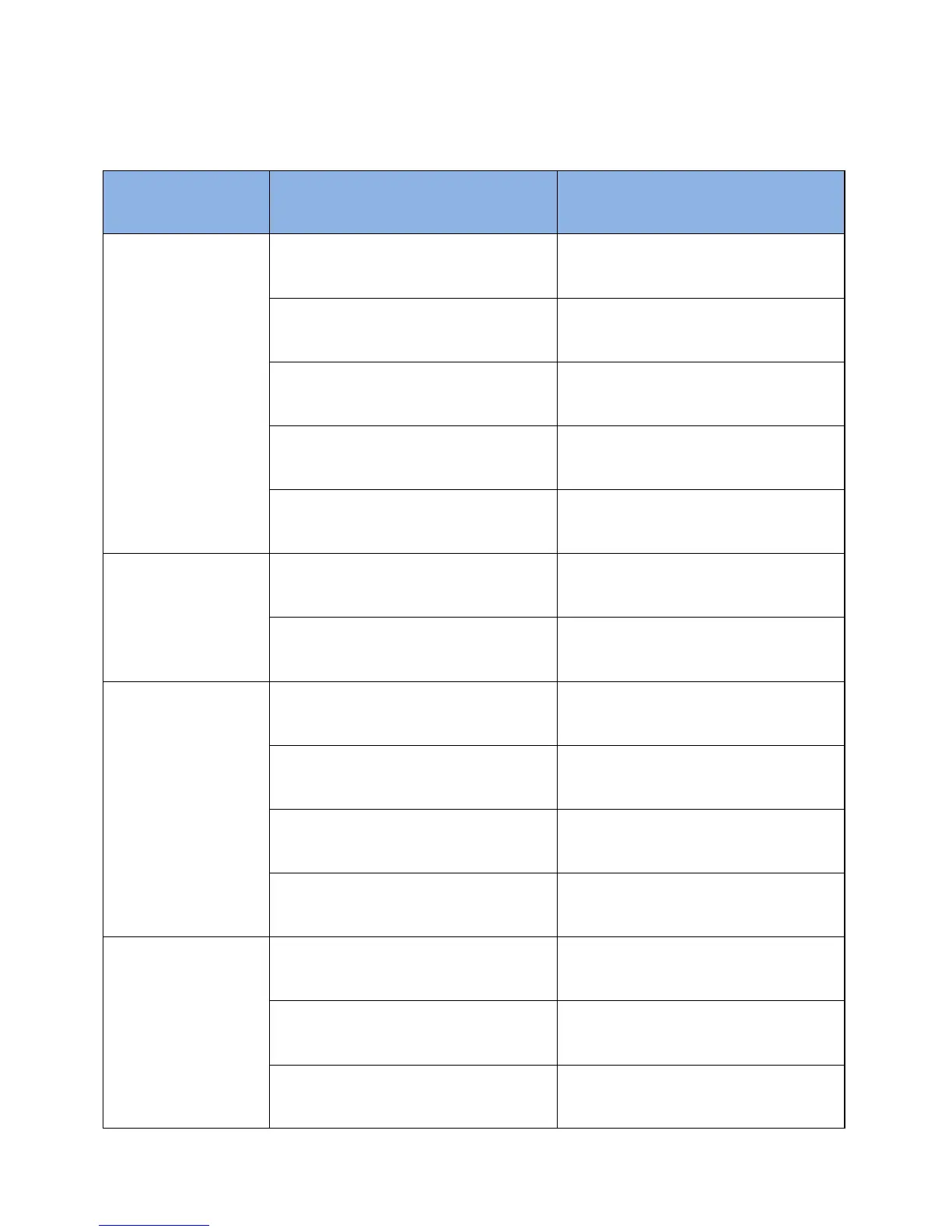

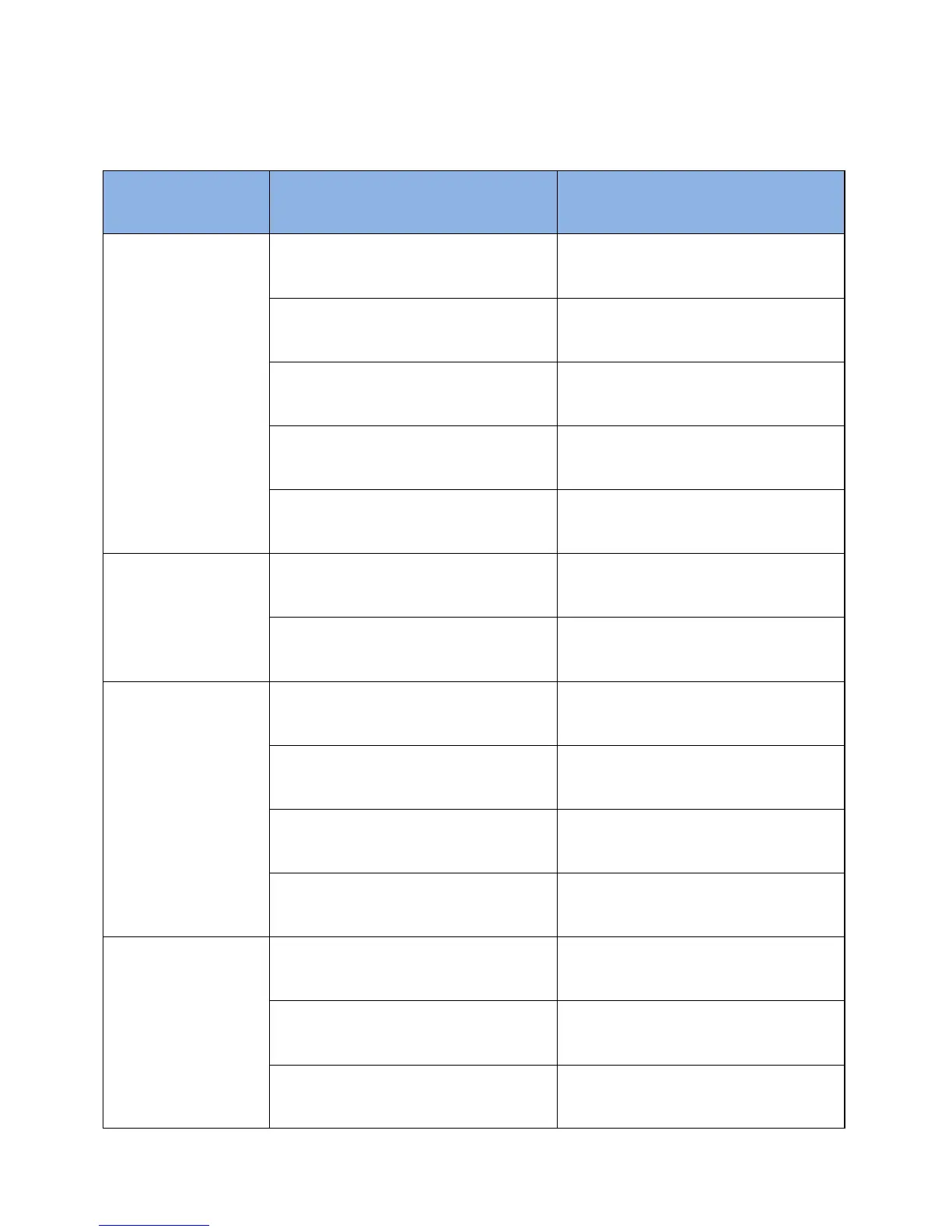

10.0 Troubleshooting

Problem Possible Cause

Solution

Ribbon Indexing insufficient

(Overlapping Prints)

Cardboard core does not fit the rewind spool cor-

rectly, or is missing.

Fit correct cardboard core, ensure that it is a good fit

on the hub.

Foil not attached to cardboard core correctly.

Use adhesive tape to attach the ribbon to the card-

board core and wind on a few turns.

Printer rods or printhead assembly are dirty.

Clean printer rods and printhead as described in

maintenance section.

Brake belt on feed spool is damaged, worn or dirty. Renew brake belt.

Tension arm spring tension on brake belt not set

correctly.

Adjust brake belt correctly, when functioning cor-

rectly the tension arm should be about 6mm from the

stop pin.

Ribbon Indexing Excessive

The Format design has a space before printing any

characters.

Change the format design so there is only 1mm from

the “X” datum to the first characters to be printed.

Ribbon may be sticking to substrate being printed,

and being pulled along.

Adjust the printhead position from the substrate,

possibly the clearance is insufficient and the foil is

being indexed along with the substrate. Service

Engineer may be required.

Ribbon Breaking or

Perforated

Printhead rods, rollers or printhead assembly are is

dirty.

Clean printer and printhead as described in mainte-

nance section.

Ribbon may be sticking to substrate being printed

and being pulled along.

Adjust the Printhead position from the substrate,

possibly the clearance is insufficient and the foil is

being indexed along with the substrate. Service

Engineer may be required.

Temperature “BURN” values may be set to high for

the substrate being printed.

Reduce “BURN” values of format to achieve accept-

able print quality.

Ribbon indexing problems, prints overlapping each

other, weakening the ribbon.

See above for overlapping prints.

Ribbon Tracking

Printer fixed rods, lower roller or printhead assembly

are dirty, through build up of wax/resin residue.

Clean fixed rods, lower roller and printhead as de-

scribed in maintenance section.

Ribbon may be sticking to substrate being printed,

and being pulled to one side.

Adjust the printhead position from the substrate,

possibly the clearance is insufficient and the foil is

being indexed along with the substrate. Service

Engineer may be required.

Printer may have been dropped, damaging the lower

roller or damaged tension arm.

Call for Service Engineer or send back to manufac-

turer for checking.

10.2 Ribbon Problems

Loading...

Loading...