Serie

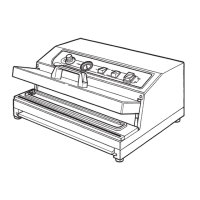

VGP25N / VGP60N

Operating and service manual

Manuale d’uso e manutenzione

Mode d’emploi ed entretien

Manual de uso y mantenimento

Bedienungs- und Wartungsanleitung

Manual Code 1500160 - Rev. 08 - 04/2017

Sede legale e amministrativa:

ORVED S.p.A. con SOCIO UNICO

Via dell’Artigianato, 30 - 30024 MUSILE DI PIAVE (VE) ITALY -

Tel.: ++39 0421 54387 / Telefax: ++39 0421 333100

MACHINE FOR HEAT SEALING TRAYS IN MODIFIED ATMOSPHERE

TERMOSIGILLATRICE DI VASCHETTE IN ATMOSFERA MODIFICATA

THERMOSOUDEUSE DE BARQUETTES EN ATMOSPHÈRE MODIFIÉE

TERMOSOLDADORA DE CUBETAS EN ATMÓSFERA MODIFICADA

SCHALENSIEGELMASCHINE IN MODIFIZIERTER ATMOSPHÄRE

E-mail: orved@orved.it - Web site: www.orved.it