Manuale d’istruzione

Operating and service manual

Mode d’emploi et d’entretien

Bedienungs- und Wartungshandbuch

Manual de uso y mantenimiento

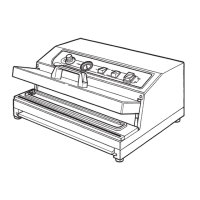

MULTIPLE 315VM P4-P8 / VM12 / VM16

VM18 / VM18 H / VM53 / VM53 H

VM1800 / VM19 / VM20 / VM30

VM20 TANDEM

CONFEZIONATRICI SOTTOVUOTO A CAMPANA

VACUUM CHAMBER PACKAGING MACHINES

CONDITIONNEUSES SOUS VIDE À CLOCHE

KAMMER - VAKUUM-VERPACKUNGSMASCHINEN

MÁQUINAS ENVASADORAS AL VACÍO DE CAMPANA

REV. 00

Ed. 10 - 2005

Cod.: 1500154

I

GB

F

D

E

ORVED Srl Soc. Unipersonale - Via dell'Artigianato, 30 - 30024 MUSILE DI PIAVE (VE) ITALY

Tel.: ++39 0421 54387 - 340340 / Telefax: ++39 0421 333100 - 332295

E-mail: orved@orved.it - orved.ve@tin.it - Internet: www.orved.it

AZIENDA CON

SISTEMA DI GESTIONE

PER LA QUALITÁ

CERTIFICATO DA DNV

=UNI EN ISO

9001:2000=

COMPANY WITH

QUALITY MANAGE-

MENT SYSTEM

CERTIFIED BY DNV

=UNI EN ISO

9001:2000=