9

S-176-9-E

Rotors

Pulse Generator

6. DISASSEMBLY AND INSPECTION

◎

While recommended servicing intervals vary according to the given operating conditions, the

g

eneral rule to follow is to perform periodic disassembly and inspection once a year.

◎

Refer to the exploded views on pages 12 to 14.

6.1 Meter Body Disassembly and Inspection

Complaint - Fluid will not run.

The most likely cause is that scales become jammed in the oval rotors, making them immovable

and blocking the uid ow.

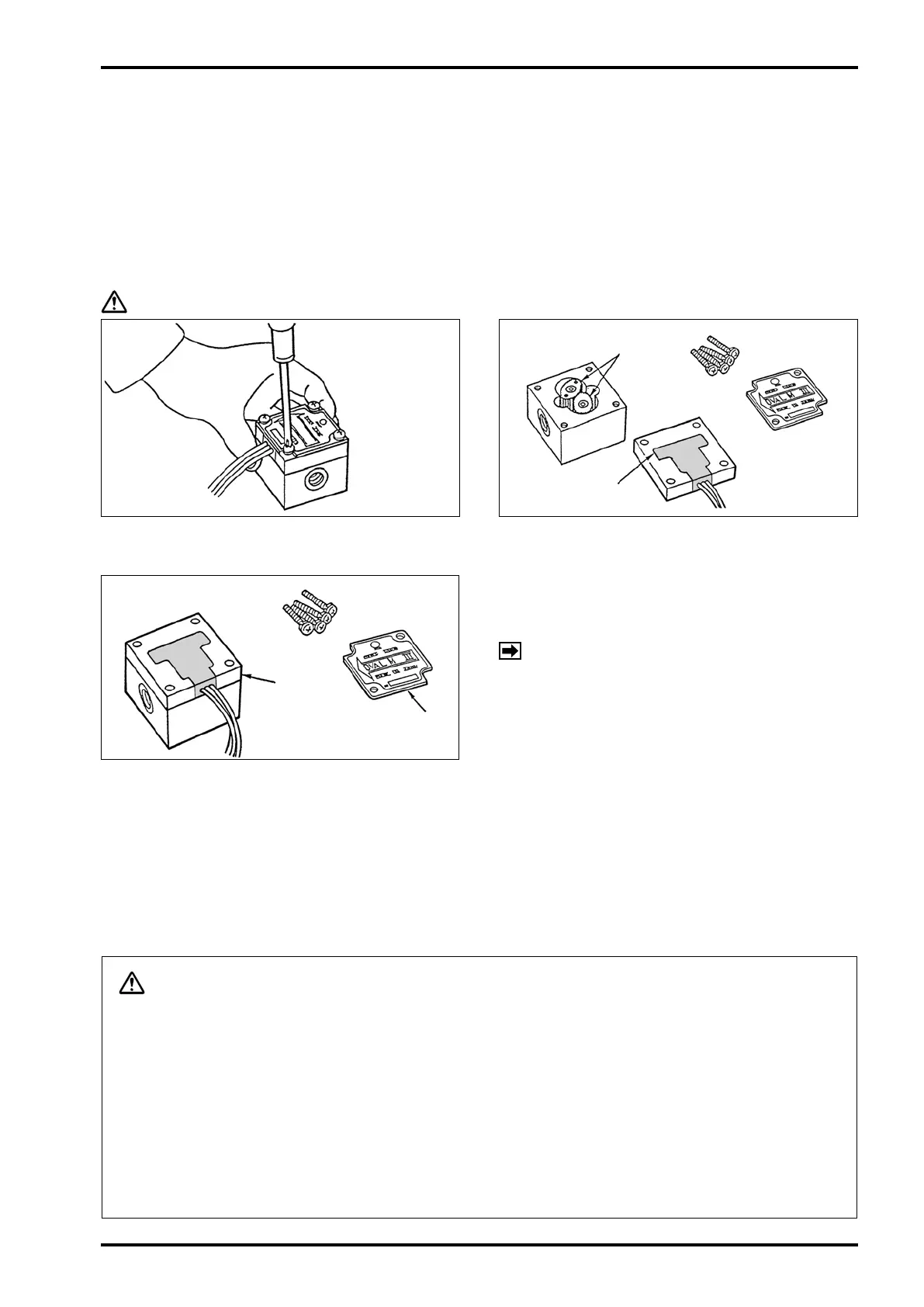

CA

UTION: Be sure to turn off power before you start servicing.

①

Take off all four pan head with cross point

screwdriver.

②

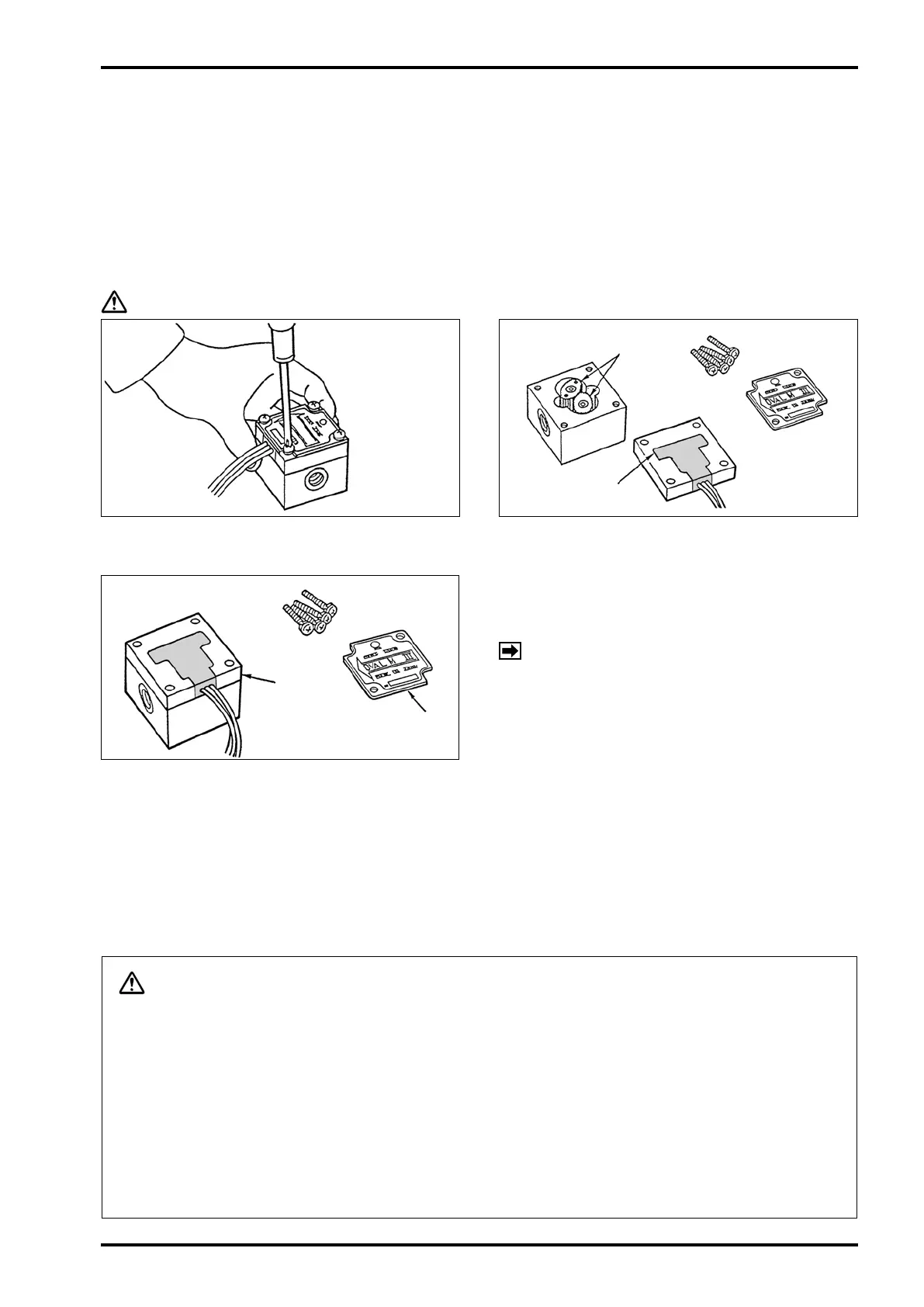

With pan head screws taken off, the front cover

and pulse generator are now separable from

the meter body. Be careful not to drop the meter

body.

Pan Head Screws

Nameplate

Front

Cover

③

With the front cover removed, the measuring

chamber and oval rotors are accessible.

④

Remove the oval rotors from the measuring

c

hamber and inspect individual component

parts for condition.

NOTE:The rotor shafts should be drawn out

axially.

(a) Are oval rotors jammed by foreign solids?

(b) Are rotors, shafts and other components

worn?

(c) Are the inner walls of measuring chamber

and front cover damaged?

(d) Are signal generating magnets rusted?

Upon completion of these inspections, wash

clean the oval rotors, rotor shafts, measuring

chamber and front cover thoroughly with fresh

water or cleaning oil.

CA

UTION

1. Deep scoring, high spots caused by impressions, or other irregularities, should be

reconditioned to be smooth and flat with oilstone.

2. FLOW MATE (OVAL M-

Ⅲ

) is a precision instrument. Disassembly and inspection should

be conducted indoors as a general rule. If it is desired to make disassembly and

inspection without removing the meter from the tubing assembly, reduce internal pressure

in the tubing assembly completely to zero, shut off valves upstream and downstream of

the meter completely, drain the tubing assembly and then place a suitable liquid receptacle

immediately below the meter. Use extra care to keep out dirt, sand or other contaminants from

disassembled component parts.

Loading...

Loading...