T-518-11-E

4

109

108

110

111

126

118 115

Terminal box

117

PG30 PG30EP

※

116

※

Gear Train Bearings

Brake Shoe

Spur Bevel Plain Ball

G2 G2 L3 L3 L3

Symbol Viscosity or Consistency Pour Point or Drop Point Example of Products by Trade Name

L3 36.4

cst

/30℃ − 37.5℃

Nisseki Launa 40

(Nippon Oil Co., Ltd.)

G2 300/25℃ 300℃ and above

Jun BG Grease

(Nihon Tokushu-koyu Co., Ltd.)

●

Lubricating Oil Specications and Examples of Products

■

LUBRICATION

Do not fail to use proper lubricants shown below, or equivalent, at disassembly and inspection.

L: Lubricating oil

G: Grease

●

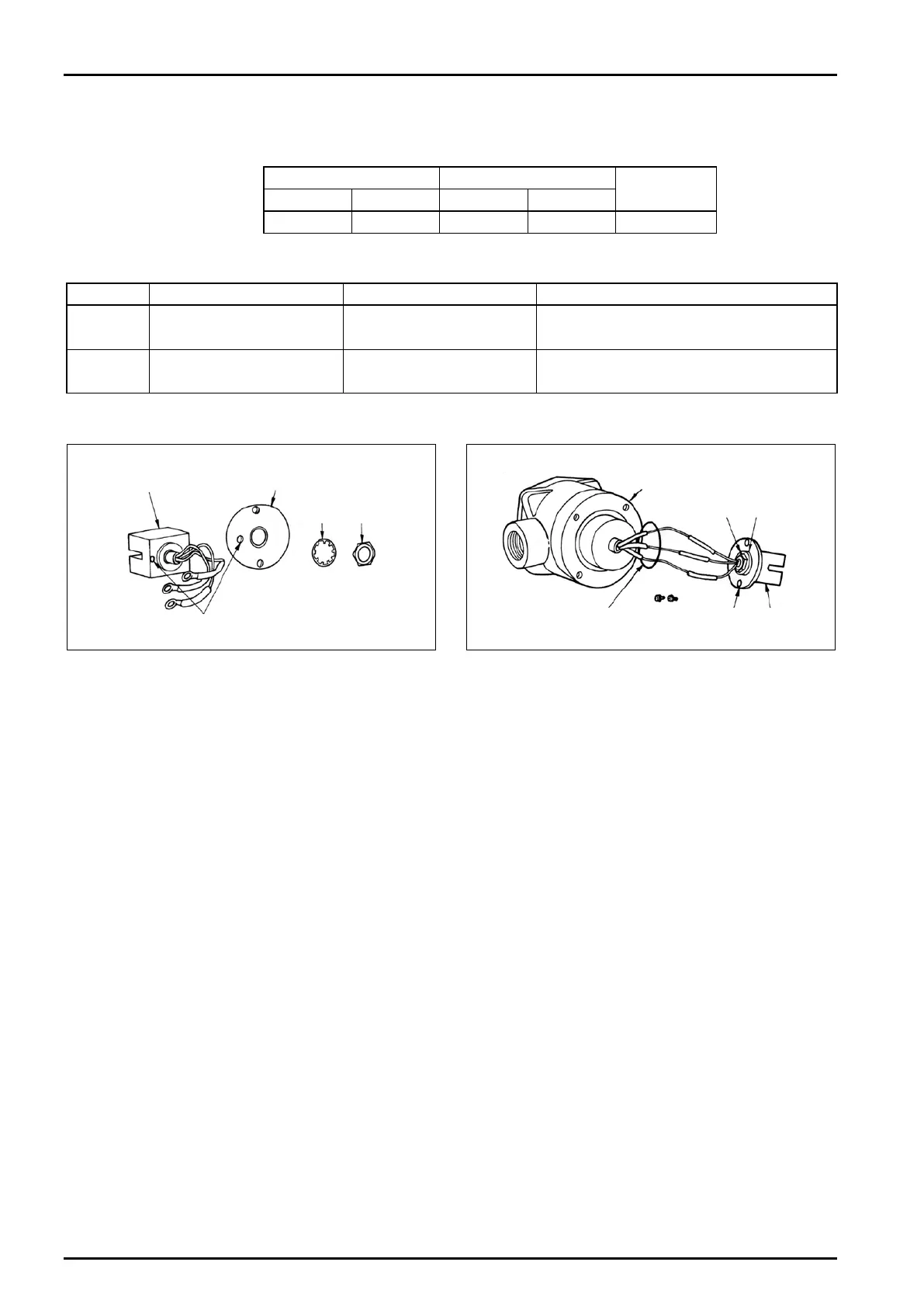

Noncontact Switch Unit Replacement

Fig. 9

Fig. 8

1. Disconnect wiring connections. Take off two

terminal fitting screws (106) and remove terminals

(104). The noncontact switch unit (108) can be

separated by taking off two additional screws (130).

2. Remove nut (110) and toothed washer (109)

holding the noncontact switch unit (108) to

mounting bracket (111), and remove the switch

unit. Install a new switch unit in alignment with

locating slot (marked ※ ). Ensure correct wiring

connections with due regard to color coded leads

(white, red and black).

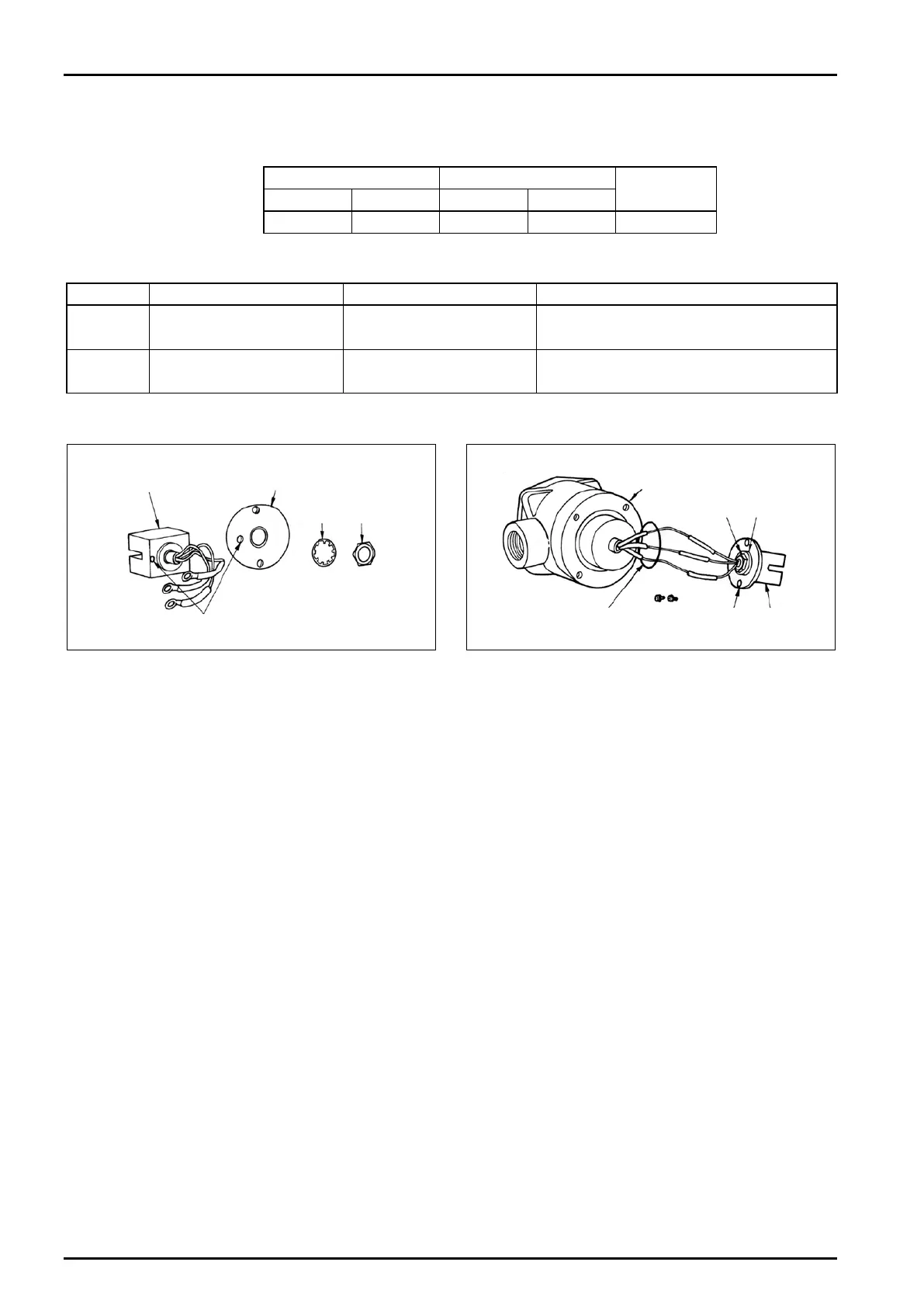

1. Take off four bolts (329) and remove the casing

of pressure-resistant gasket (301) from housing

(101). Then, take off two screws (126) securing the

noncontact switch unit (115) in place and remove

the switch unit.

2. Unsolder wire lead connections (marked ※ ), take

off nut (117) and toothed washer (116) holding the

noncontact switch unit (115) to mounting bracket

(118), and separate the switch unit.

Replace with a new noncontact switch unit in the

same manner as described for PG30 pulse generator

and solder wire leads to their connections.

Loading...

Loading...