MAINTENANCE (cont.)

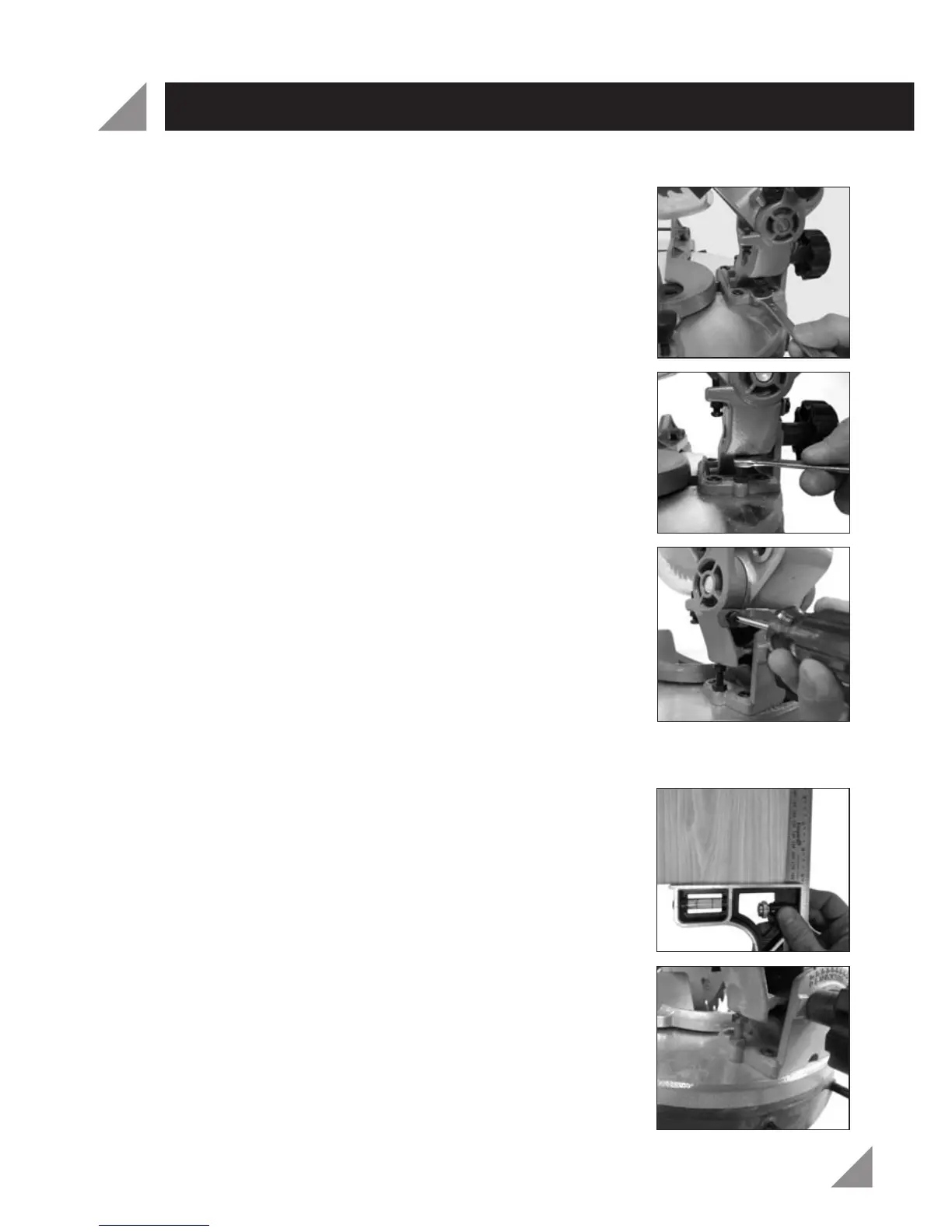

If the blade (10) angles away from the set square, adjust as follows.

12. Loosen the bevel lock knob (13) by turning in an

anti-clockwise direction.

13. Use a 10mm spanner (not supplied) to loosen the

0° bevel adjustment nut (Fig. 33).

14. To bring the blade into alignment with the set square

adjust the 0° bevel adjustment screw (16) using a

10mm spanner (not supplied) (Fig. 34).

Turning the 10mm spanner in a clockwise direction will

increase the bevel angle (move it above 0°). Turning

the 10mm spanner in an anti-clockwise direction will

decrease the bevel angle (move it below 0°).

15. Once the blade is aligned with the set square use a

Phillips Head screwdriver (not included) to loosen the

bevel angle indicator (12) (Fig. 35).

16. Using a Phillips Head screwdriver (not included),

loosen the bevel angle indicator (12) by turning in an

anti-clockwise direction (Fig. 35).

17. Adjust the position of the bevel angle indicator (12) so

that it accurately indicates 0° on the bevel scale (14).

18. Re-tighten the bevel lock knob (13) and the 0° bevel

adjustment lock nut (16).

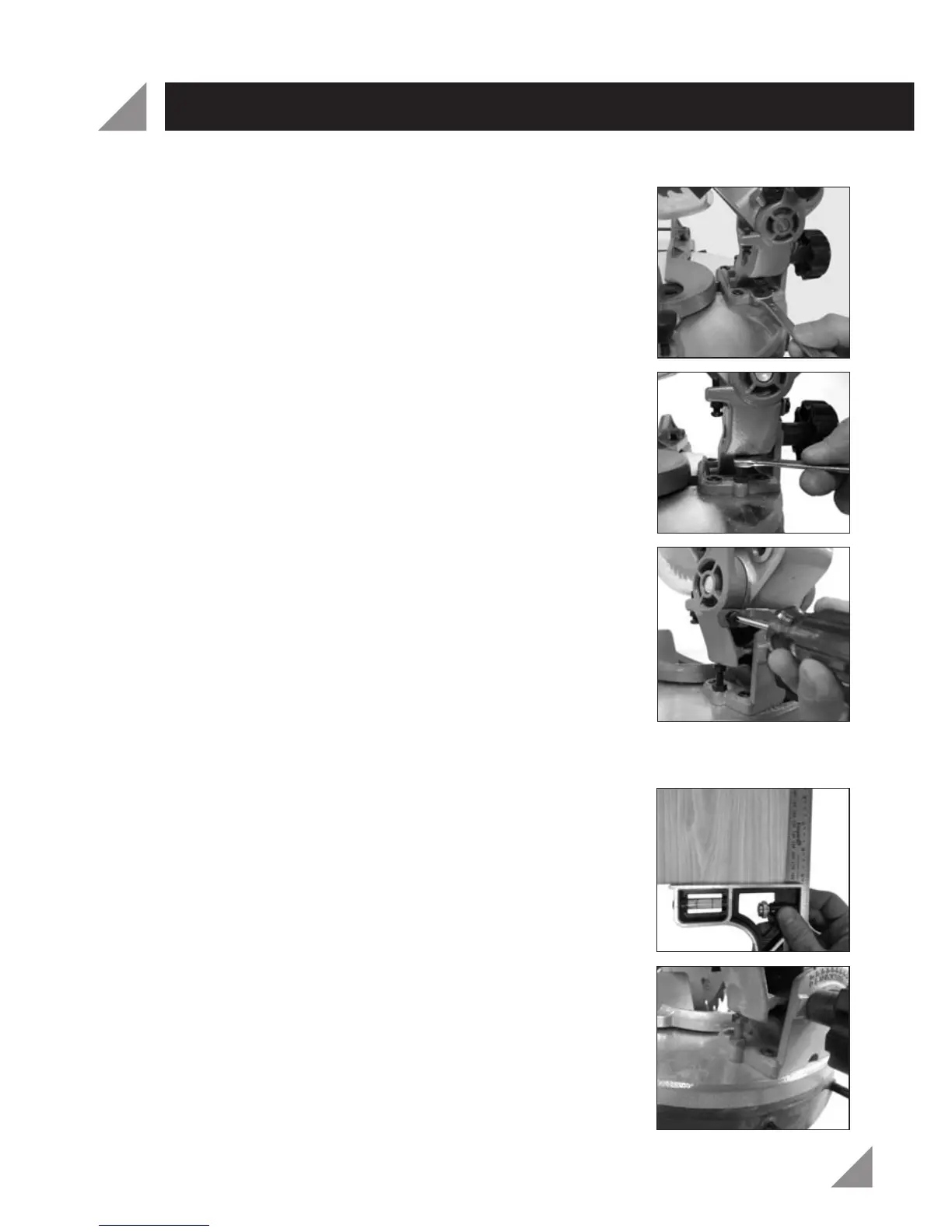

19. Using a scrap piece of wood, perform a straight cut at 0°.

20. Use a set square (not included), to check that the cut is

accurate (Fig. 36).

21. If the cut is not square, repeat steps 1-20 to set the

rotating mitre table (23) square with the blade (10).

NOTE: Using a 45° square the above procedure can also

be used to check the angle of the blade (10) to the

rotating mitre table (23) at a 45° bevel angle. The 45°

bevel adjustment screw (15) is located on the opposite

side to the 0° screw (Fig. 37).

Fig.

33

Fig. 34

Fig. 35

Fig. 36

Fig. 37

18

Loading...

Loading...