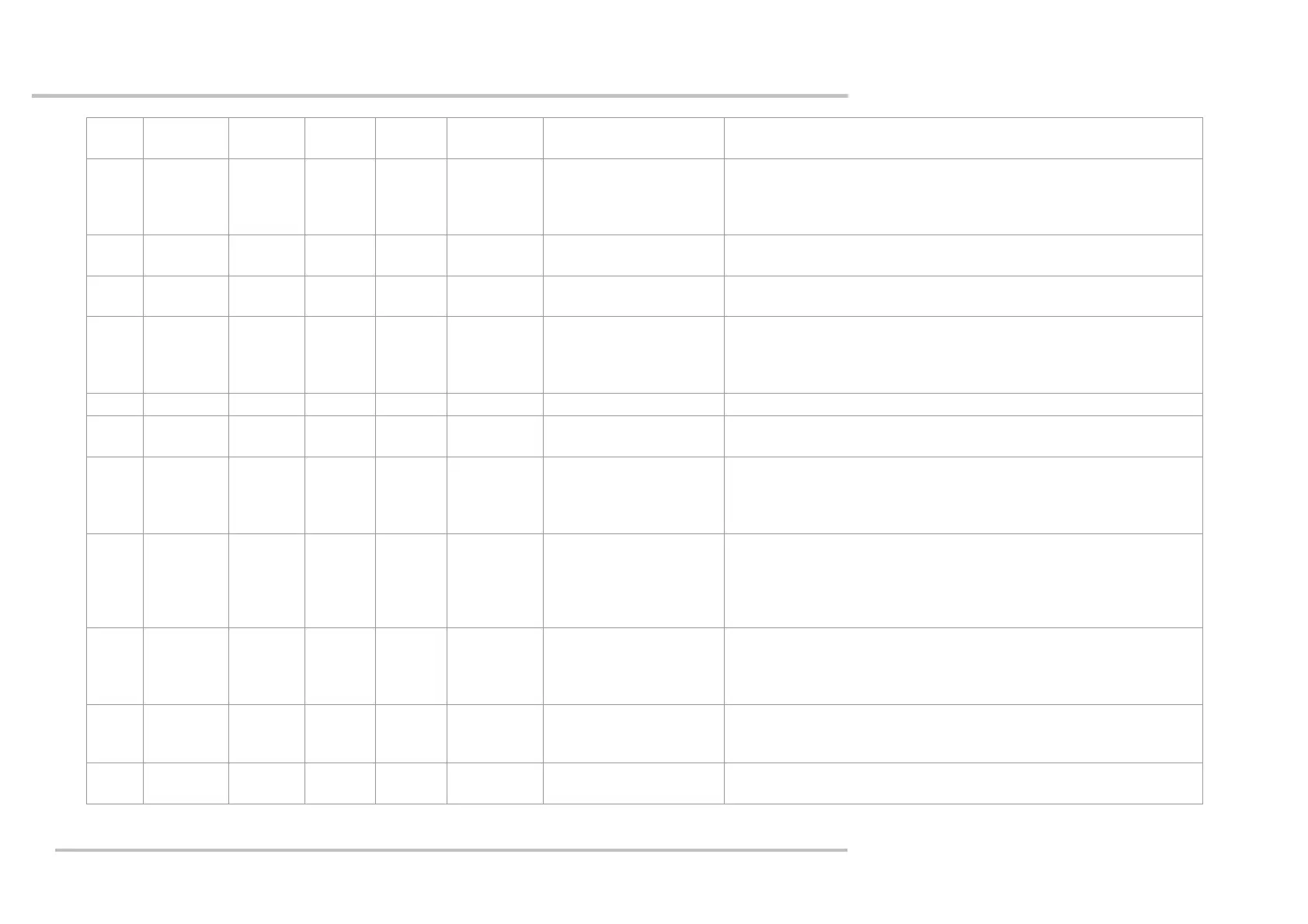

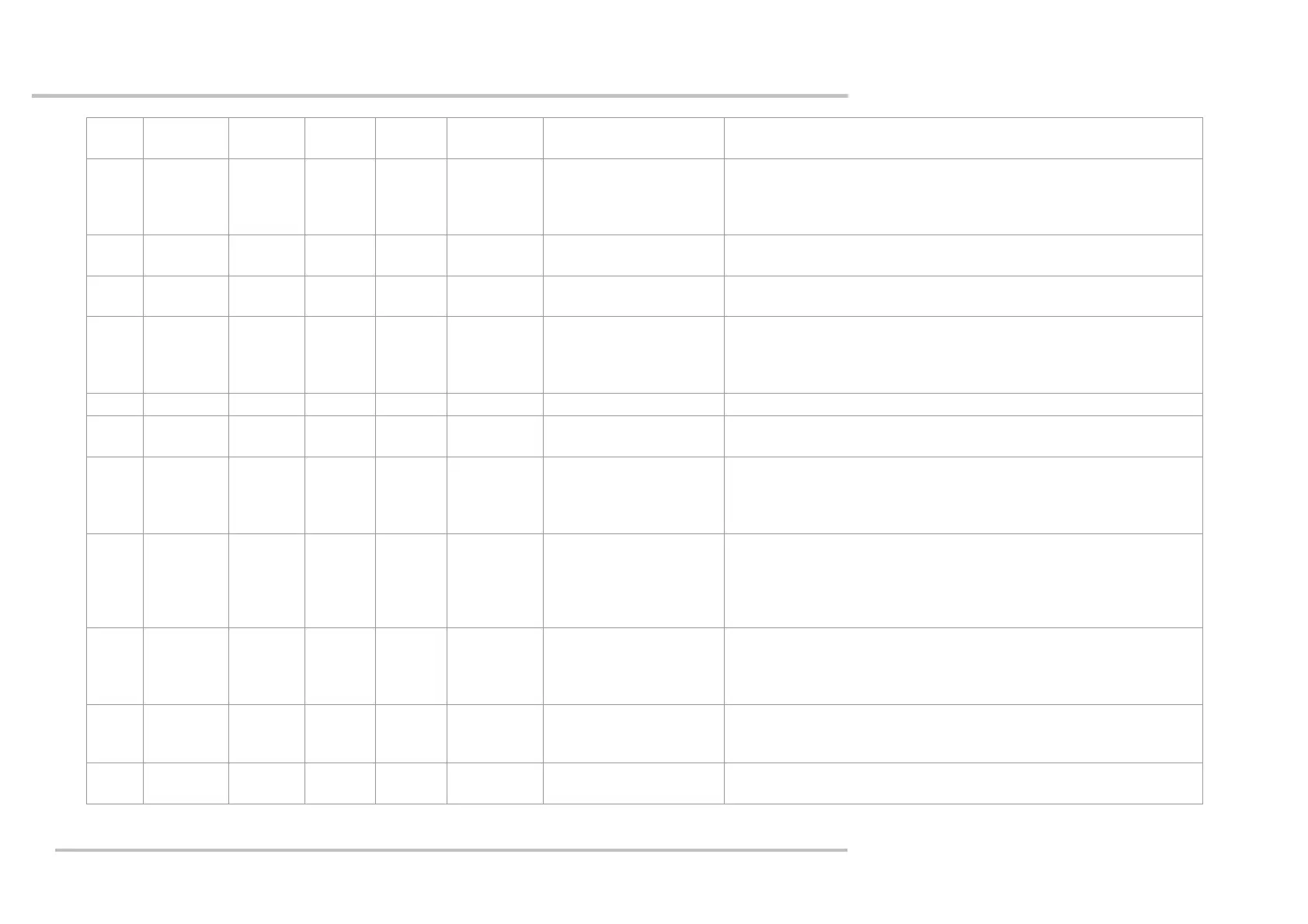

Code list TC161

14

Subject to change without notice

55

Code-

Nr.

Password

protected

Set

value

Limit

-

Limit

+

Unit Title Description

116 yes 50 0 Direction counter 5 In stream delivery mode, this is the maximum the belts move the

sheet forward as it arrives. The distance is calculated from the

calibrated value. Standard value is 50% of the calibrated sheet

length.

117 yes 50 0 200 in % of the

sheet length

Max. distance Maximum distance of the deflector before a reaction has to occur.

118 yes 259 0 mm Direction counter 6 In stream delivery mode, the start is triggered by photocells

B8/B9/B11. The transport belts start after this value has elapsed

119 no 0

1

2

3

0 3 Language 1

Language 2

Language 3

Language 4

German

English

Dutch

120 no 0 Photocell on the sheet run 0=all, 1=B8, 2=B11, 3=B9

121 yes 2000 1000 5000 ms Delay 16 Welding time monitoring. If the heating dies are heated for a long

time, the machine stops with error 18.

122 no 20 20 5000 ms Delay 6 After reaching the pre-selected batch piece value, the elevation

table moves into the intermediate position and stops after photocell

B18 is released. Photocell B18 must remain free for at least this

period of time before the elevation table stops.

123 no 300 0 10000 ms Delay 7 After reaching the intermediate position, the elevation table moves

upwards until press sensor B5 responds. This is the maximum

value during which it moves up. After this value, the elevation table

is stopped and the welding process is triggered independently from

B5.

124 no 1500 ms Delay 8 Only in connection with the option "Batch level compensator".

Usually, the batch level gates are set so that they retract when they

reach the intermediate position. This retraction can be delayed by

increasing this value.

125 yes 1500 ms Delay 9 After activation, the pressing guides must be extended at the latest

after this length of time (B3). If not, the machine will stop with Error

16.

126 no 1 Running out of banding, the machine stops with Error 42 (see also

code 127).

Loading...

Loading...