•

•

•

•

•

9.8 Track

00

Sensor Adjustment

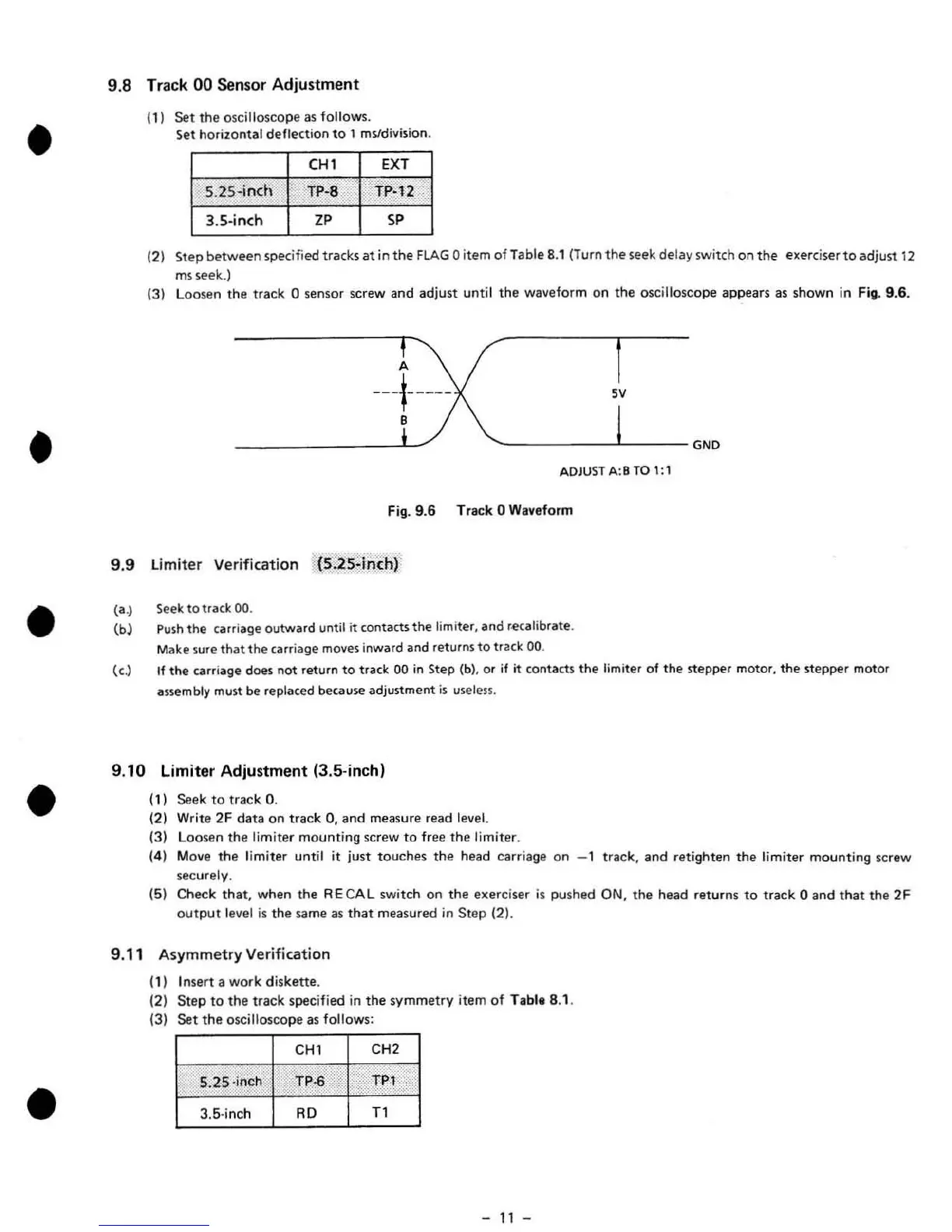

(1) Set the oscilloscope

as

follows.

Set

h

orizontal

deflection t o 1 mYdivision.

CH1

EXT

S.2S-in

ch

TP-8

Tp·12

3. 5·inch

zp

SP

(21

Step

between

specified tracks

at

in

the

FLAG

0 item

ofTable

8.1 (Turn

the

seek

de

lay switch

on

the

exercis

er

to

adjust 12

ms

seek.)

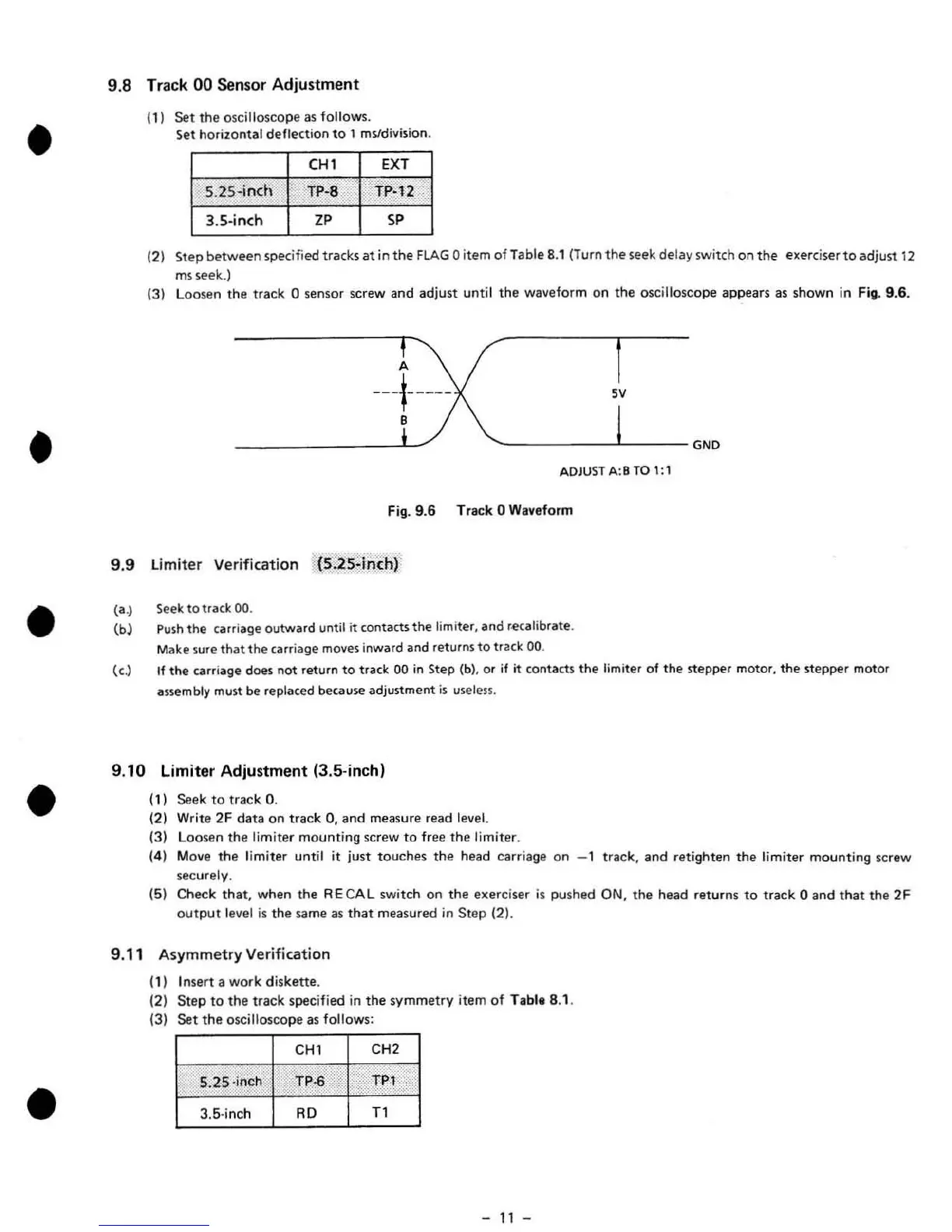

(3)

loo

sen the track 0 sensor screw and adjust until the waveform on the oscilloscope appears as shown in

Fig

. 9.6.

A

--

+

----

sv

'-------

--~------G

ND

ADJUST A:B

TO

1:1

Fig

. 9.6 Track 0 Waveform

g,g

limiter

Verification

(S

;

)S:inchr

(a

.)

(b)

Seek

to

track

00

.

Push

the

carriage

outwllrd

until

it

contacts

the

lim

i

ter

, and recOlIlibrate.

Make sure

that

the

carriage moves inward and returns

to

track 00.

{el

If

the carriage does not return

to

track

00

in

Step

(b),

or if

it

contacts

the

limiter of the stepper motor.

the

stepper motor

assembly must be replated because adjustment

is

u§eless

.

9.

10

limiter

Adjustment (3.5-inchl

(11

Seek

to

track O.

(21

Write 2F

data

on

track

0,

and

measure read level.

(31

Loosen

the

limiter

mounting

screw

to

free

the

limiter.

141

Move

the

limiter until it just

touch

es

the

head carriage

on

- 1 track.

and

retighten

the

limiter

mounting

screw

securely.

(5) Check

th

at, when the A E

CA

L switch

on

the

exerciser

is

pushed ON,

the

head returns

to

track 0 and

that

the

2F

output

level

is

the

same

as

that

measured in

Step

(21.

9.11 Asymmetry Verification

(1) I nsert a work diskette.

(2)

Step

to

the track specified in

the

symmet

ry

item

of

T

ab

le 8.1.

(3)

Set

the

oscilloscope

as

follows:

CH

1

CH2

S.

2S

-inch

TP-6

..

II

TP'

/

3.5

·inch

RD

T1

-

11

-

Loading...

Loading...