Prop. Directional Control Valve

Series D*FB / D*1FB

Operation Manual

11

Parker Hannifin CorporationParker Hannifin Corporation

D_FB-D_1FB_10-12 5715-669 UK.indd 25.06.19

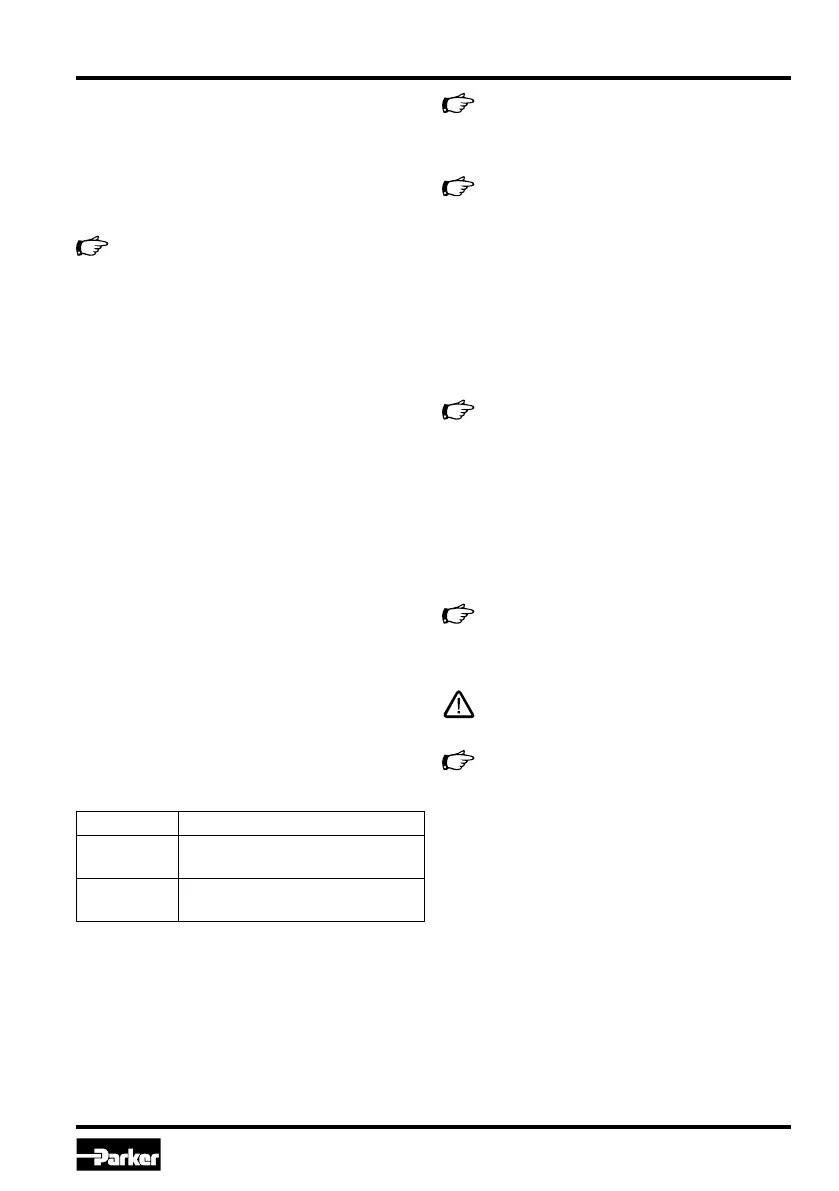

Storage time Conditions

12 months

Stable air humidity 60 % and sta-

ble temperature < 25 °C

6 months

Fluctuating air humidity and fluctu-

ating temperature < 35 °C

3. Use of the product

Transport

Depending on size, lifting equipment or transport

aids are needed. Our product leaves the factory in

perfect working order, and appropriate packaging

is used to protect it from damage.

The condition of the product on arrival is no

longer under our control, so please check for

transport damage/defects immediately after

arrival. Document the transport damage and

immediately notify the carrier, the insurance

company and the manufacturer. Do not dis-

pose of the packaging unless there is no trans-

port damage and the entire package contents

have been removed from the packaging. If

the product has been damaged during trans-

port, it must be exchanged for a new one.

When transporting the product within your premis-

es, make sure it is kept in a safe position and pro-

tected in its original packaging until it is ready to

use. Note also the information in sections “Warranty

and liability”, “Basic information on using the man-

ual”, "Other applicable standards/rules", “Person-

nel requirements”, “Remaining risks”.

Storage

If the product needs to be temporarily stored, it

must be protected from dirt, the weather, and dam-

age. Each valve is tested with hydraulic oil in the

factory, so that the internal components are pro-

tected from corrosion. However, this protection can

only be guaranteed under the following conditions:

The product is delivered with adequate corrosion

protection, provided our recommendations for the

ambient conditions are followed.

Storage outside or in maritime or tropical cli-

mates without appropriate packaging leads

to corrosion and may make the product un-

usable.

Make sure the product is stored so that no

injuries can be caused by tipping or falling. In

particular, make sure that the safety rules for

high-bay racking are followed.

Commissioning

After installing our product in a system/machine,

make sure that the requirements of the Machinery

Directive are met if applicable. Access should be

provided to the hydraulic diagram, the equipment

list and the logic diagram for the system/machine.

The product must be checked for damage

and missing parts (e.g. seals) before instal-

lation, especially in the area of the sealing

surfaces and the safety devices. If the safe-

ty devices or sealing surfaces are damaged

or are missing individual parts with relevance

to the product's function, the product may not

be used.

Remove all transport securing devices, protective

covers and packaging.

Check for foreign objects in the open hydrau-

lic passages. Contaminations may impair op-

erational reliability and shorten the service

life.

Make sure that the hydraulic system/machine

is unpressurised before the product is in-

stalled.

Before commissioning, the specialist person-

nel must verify that the entire hydraulic sys-

tem has been installed correctly. Commis-

sioning must be carried out with care, taking

account of all safety regulations.

If necessary, erect warning signs to prevent unin-

tended operation. Note also the information in sec-

tions “Warranty and liability”, “Basic information on

using the manual”, "Other applicable standards/

rules", “Personnel requirements”, “Remaining risks”.

Compare valve type (located on the name plate)

with part list resp. circuit diagram.

Loading...

Loading...