26

Prop. Directional Control Valve

Series D*FB / D*1FB

Operation Manual

Parker Hannifin CorporationParker Hannifin Corporation

D_FB-D_1FB_10-12 5715-669 UK.indd 25.06.19

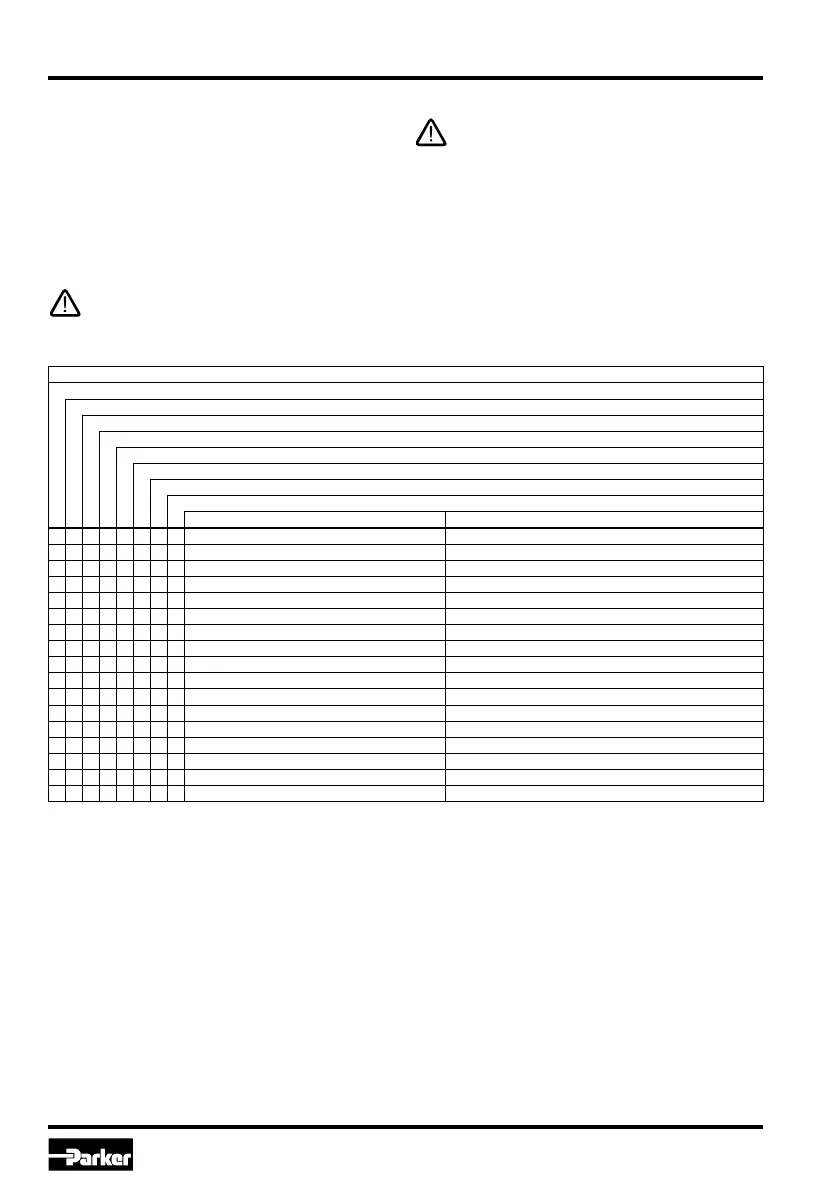

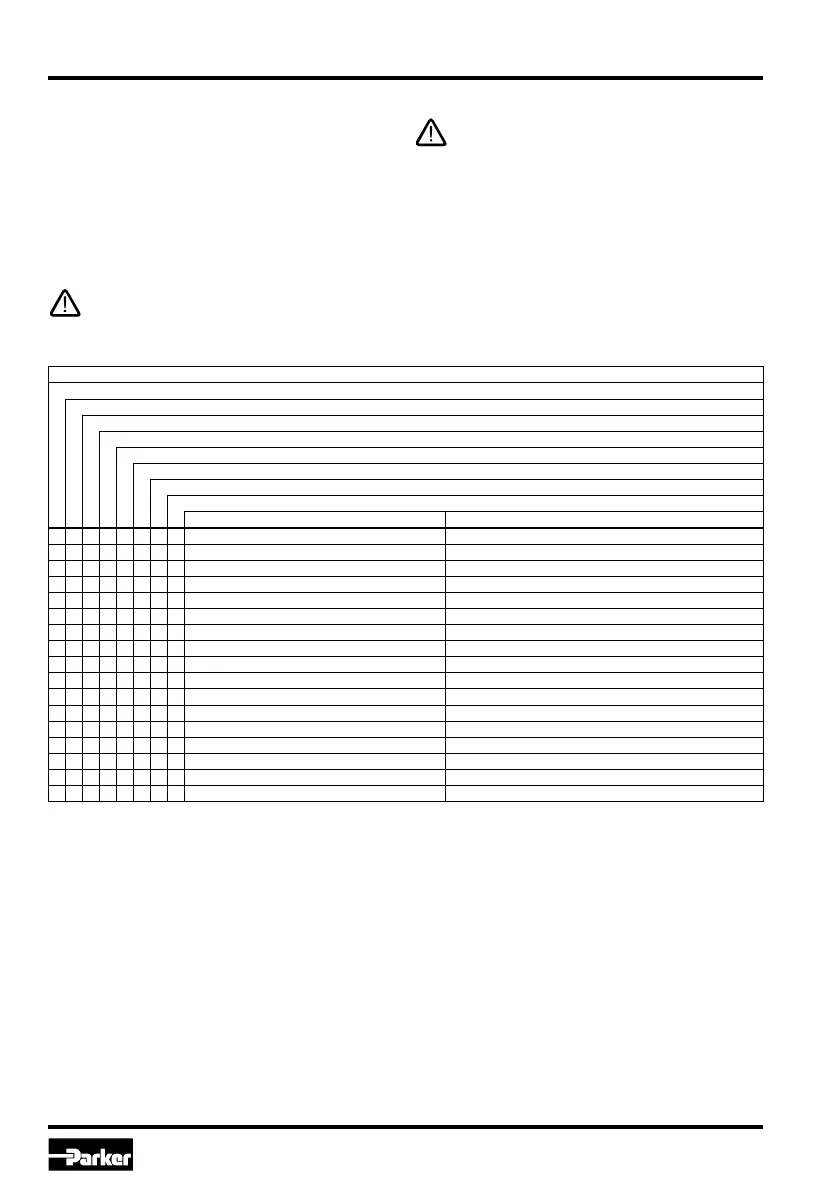

malfunction at hydraulic load runtime

- generally no function

- high frequent oscillation

- low frequent oscillation

- one way operation only

- speed variations at unchanging command

- different speeds depending on travel direction

- speed too low

- drifting without command

possible reasons for malfunction corrective actions

x hydraulic pump resp. motor defective replace hydraulic pump resp. motor

x x x x x x drive overloaded reduce pressure resp. speed, increase valve size

x x x x x x x valve contaminated clean pressure fluid, filter / flush valve

x x hydraulic fluid too viscous / too cold change fluid grade, provide operational temperature

x x x too low oil level within tank refill pressure fluid

x x x filter contaminated clean resp. replace filter

x x x x supply voltage too low keep supply voltage range

x supply voltage carries too much ripple reduce ripple

x x x command signal too low increase command signal

x command signal carries too much ripple reduce ripple

x dither signal amplitude too high reduce parameter P5

x dither signal amplitude too low increase parameter P5

x x x x x central connector contact failure clean contacts resp. replace connector

x feed cable interrupted fix feed cable

x x x x x x x wiring sequence incorrect correct wiring sequence

x x feed cable without shielding change cable grade

x

*)

pilot flow configuration incorrect correct pilot flow configuration

*)

only for D*1FB

Troubleshooting table

4. Product information

Other applicable standards / rules

• ISO 4406:1999-12 Hydraulic fluid power - Flu-

ids - Method for coding the level of contamina-

tion by solid particles

• ISO 4401:2005-07 Hydraulic valves; mounting

surfaces and connecting plates

• DIN EN 60204-1; VDE 0113-1:2007-06 Safe-

ty of machinery – Electrical equipment of ma-

chines – Part 1: General requirements

• DIN EN 60529; VDE 0470-1:2000-09 Degrees

of protection provided by enclosures (IP code)

•

DIN EN 61000-4-2/3/4/6/8 Electromagnetic

compatibility

• DIN 51524-1:2006-04 Pressure fluids - HLP

hydraulic oils - Part 1: Minimum requirements

• DIN 51525-2:2006-04 Pressure fluids - HLP

hydraulic oils - Part 2: Minimum requirements

•

German Occupation Safety Ordinance (Be-

triebssicherheitsverordnung)

• German Labour Protection Act (Arbeitsschutz-

gesetz)

Trouble shooting

Basis of troubleshooting is always a systematic

approach. At first the following questions have to

be checked:

•

Are there practical experiences with similar

failures?

• Have system adjustments been changed?

Afterwards starting of troubleshooting by means of

a priority list of the most likely reasons.

For suspect of a sluggish spool the valve may

be flushed with clean pressure fluid.

Troubleshooting in a hydraulic system requires

in either case a systematic approach. The

work may exclusively be performed by qual-

ified personnel, as it requires detailed knowl-

edge about function and construction of the

system. Reversals or disassemblies may not

be taken imprudently! Prior to the works it

has to be clarified, if the system has been op-

erated properly until the failure occured.

Loading...

Loading...