13

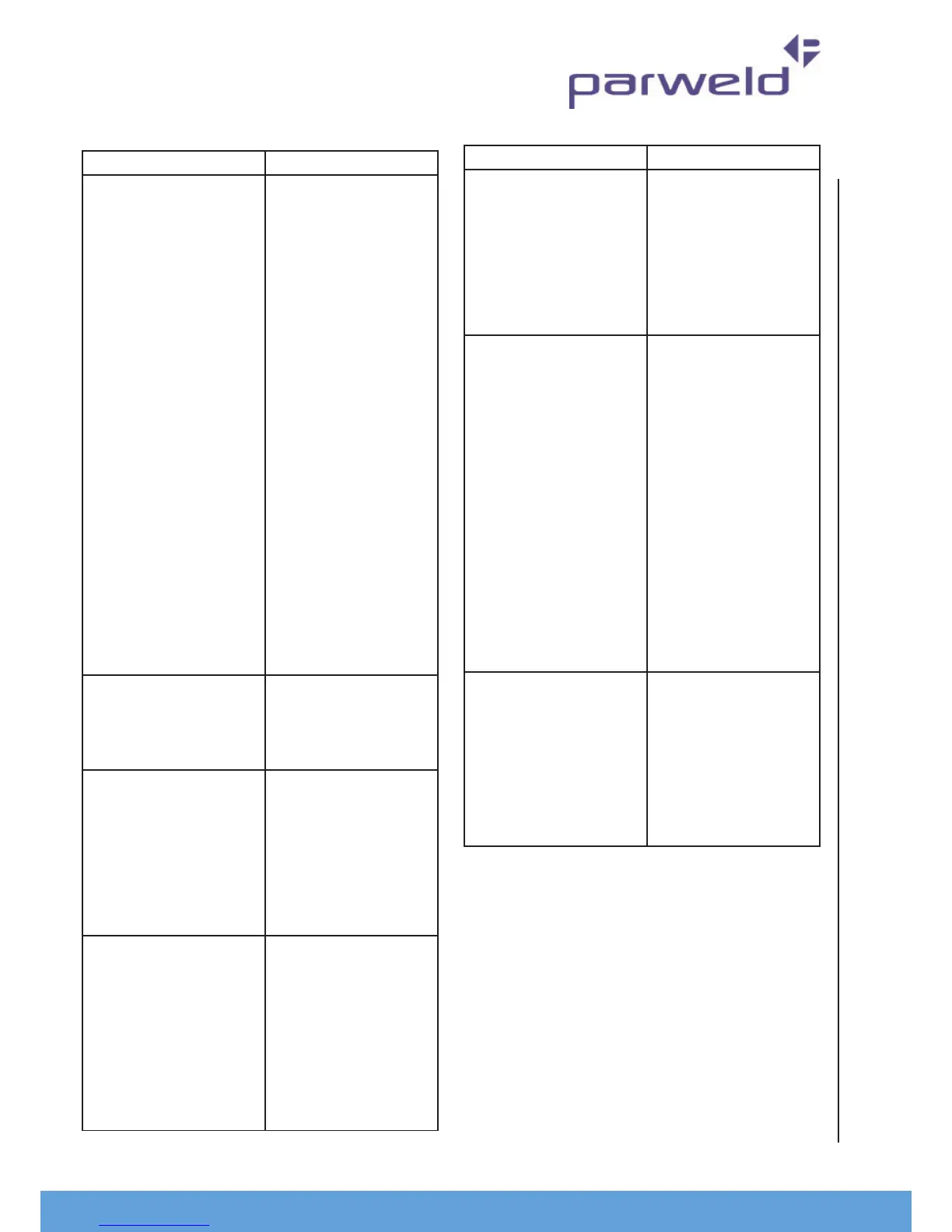

Problem Cause/Correcve Acon

Excessive Spaer -

scaering of

Molten metal parcles

that cool to solid form

near weld bead.

Wire feed speed too

high. Select lower wire

feed speed.

Voltage too high. Select

lower voltage range.

Electrode extension

(sck out) too long.

Use shorter electrode

extension (sick out).

Work piece dirty.

Remove all grease, oil,

moisture, rust, paint,

undercoang, and dirt

from work surface

before welding.

Insucient shielding gas

at welding arc. Increase

ow of shielding gas at

regulator/ow meter

and/or prevent dras

near welding arc.

Dirty welding wire. Use

clean, dry welding wire.

Eliminate pickup of oil

or lubricant on welding

wire from feeder or

liner.

Wire feed unit operates

but no gas ow .

Gas cylinder empty

Gas regulator closed

Faulty solenoid

Restricon in torch

cables

Wire feed unit operates,

but does not feed

Insucient drive roll

pressure

Incorrect drive rolls

Excessive wire spool

brake tension

Incorrect liner

Blocked liner

Bird nesng

Burn back

Bird nesng Excessive feed roll

pressure

Incorrect or blocked

liner

Incorrect contact p size

Contact p overheang

Restricon in torch

cable

Misaligned drive rolls or

wire guides

Excessive cable kinkage

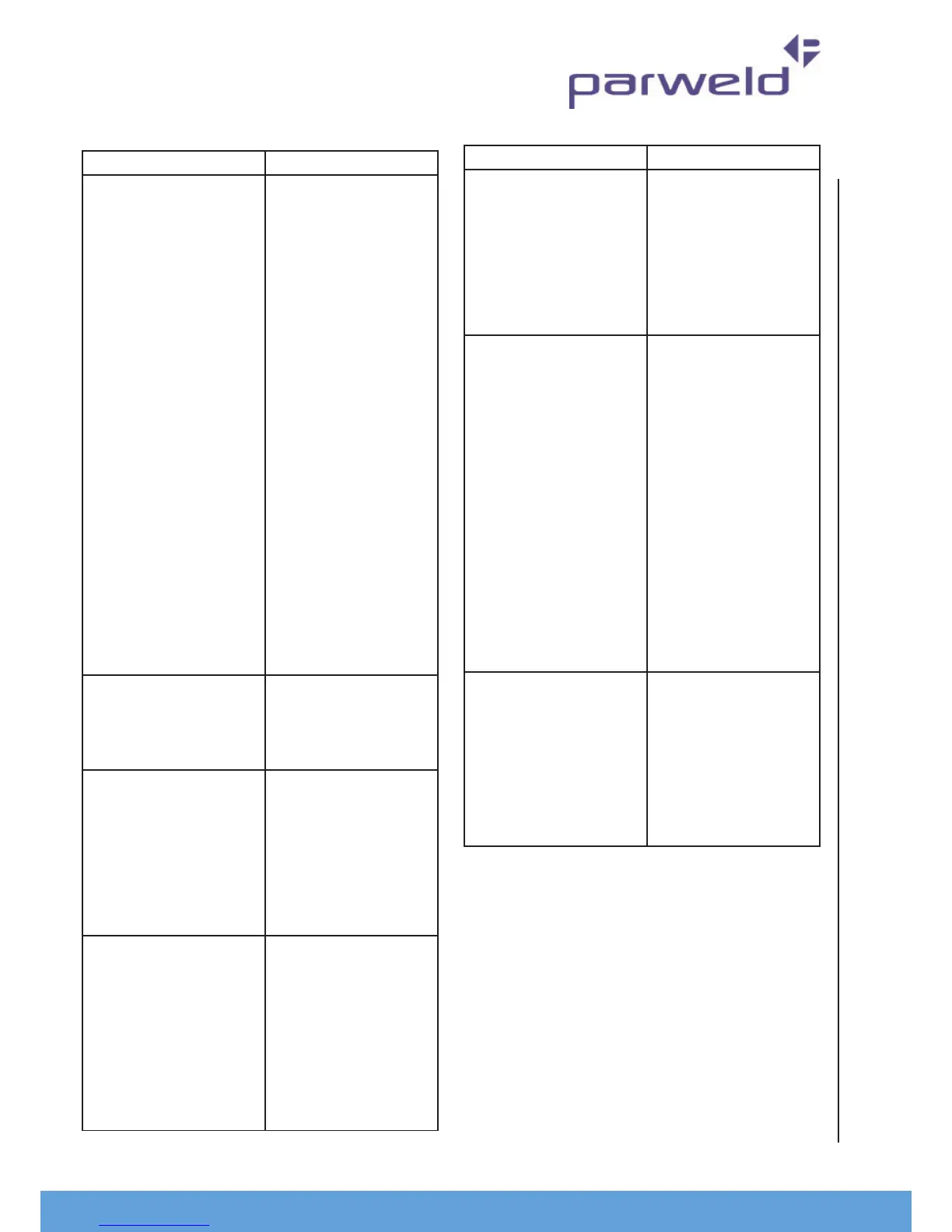

Problem Cause/Correcve Acon

Burn back Improper voltage seng

Improper sck out

Errac wire feed

Incorrect or blocked

liner

Contact p overheang

Excessive cable kinking

Adjust the burn back

control correctly

Errac Wire Feeding or

Arc

Improper drive roll

tension

Improper drive roll size

Worn drive rolls

Incorrect or blocked

liner

Incorrect wire guide size

Misaligned drive rolls or

wire guide

Gaps at liner or wire

guide juncons

Incorrect contact p size

Contact Tip overheang

Spaer adhesion on exit

geometry of p bore

Excessive cable kinkage

Poor earth or cable

connecons

Weld joint area dirty

Yellow temperature light

illuminates

Power source has

over heated leave the

machine running to

allow it to cool down.

Ensure entry and exit

vents on machine are

clear and machine has a

good supply of cooling

air.

Reduce operang duty

cycle and or amperage.

Loading...

Loading...