8

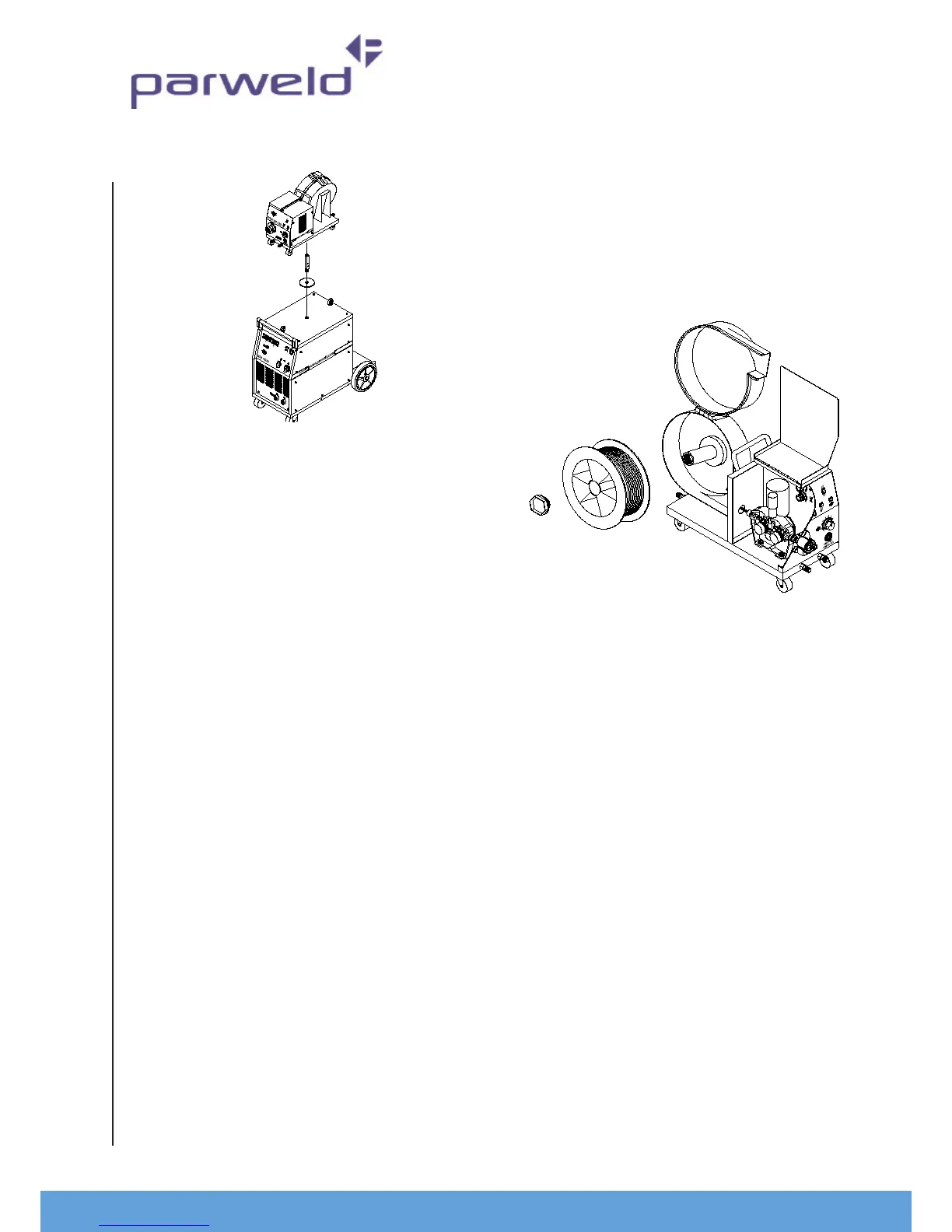

22. So start adjustment which controls the

acceleraon of the wire feed motor when the arc

starts to reduce spaer and give a cleaner arc

iniaon.

23. Burn back control aects the wire feed motor

over run when the trigger is released and can be

adjusted to ensure that the wire does not burn

back onto the contact p at the end of the weld

24. Pressure adjuster Used to adjust the pressure

allied by the feed rollers on the welding wire.

25. Shielding gas input connecon 3/8 BSP male

connecon for the shielding gas input.

26. Interconnecon cable control socket input

27. Welding power connecon.

5.0 Installaon

Read enre installaon secon before starng

installaon.

SAFETY PRECAUTIONS

• ELECTRIC SHOCK can kill.

• Only qualied personnel should perform this

installaon.

• Only personnel that have read and understood the

Operang Manual should install and operate this

equipment.

• Machine must be grounded per any naonal, local

or other applicable electrical regulaons.

• The MIG power switch is to be in the OFF posion

when installing work cable and torch and when

connecng other equipment.

5.1 Unpacking the Machine

Cut banding and li o cardboard carton. Cut banding

holding the machine to the skid. Remove corrugated

packing material. Remove accessories from Gas Bole

Plaorm.. Roll the machine o the skid

5.2 Locaon

Locate the welder in a dry locaon where there is

free circulaon of clean air into the louvres in the

back and out the front. A locaon that minimizes the

amount of smoke and dirt drawn into the rear louvres

reduces the chance of dirt accumulaon that can

block air passages and cause overheang.

5.3 Input and grounding connecon

WARNING

Before starng the installaon, check that your power

supply is adequate for the voltage, amperage, phase,

and frequency specied on the Machine nameplate.

The 400 volt 50 Hz machine is supplied with a 4m

input cable and without plug, ensure that you connect

a plug that is suitably rated for the power draw of

the machine and the environmental locaon. Have a

qualied electrician connect the input plug. For long

runs over 30m , larger copper wires should be used.

The green/yellow wire in the input cable connects

to the frame of the machine. This ensures proper

grounding of the machine when the machine plug is

inserted into the receptacle.

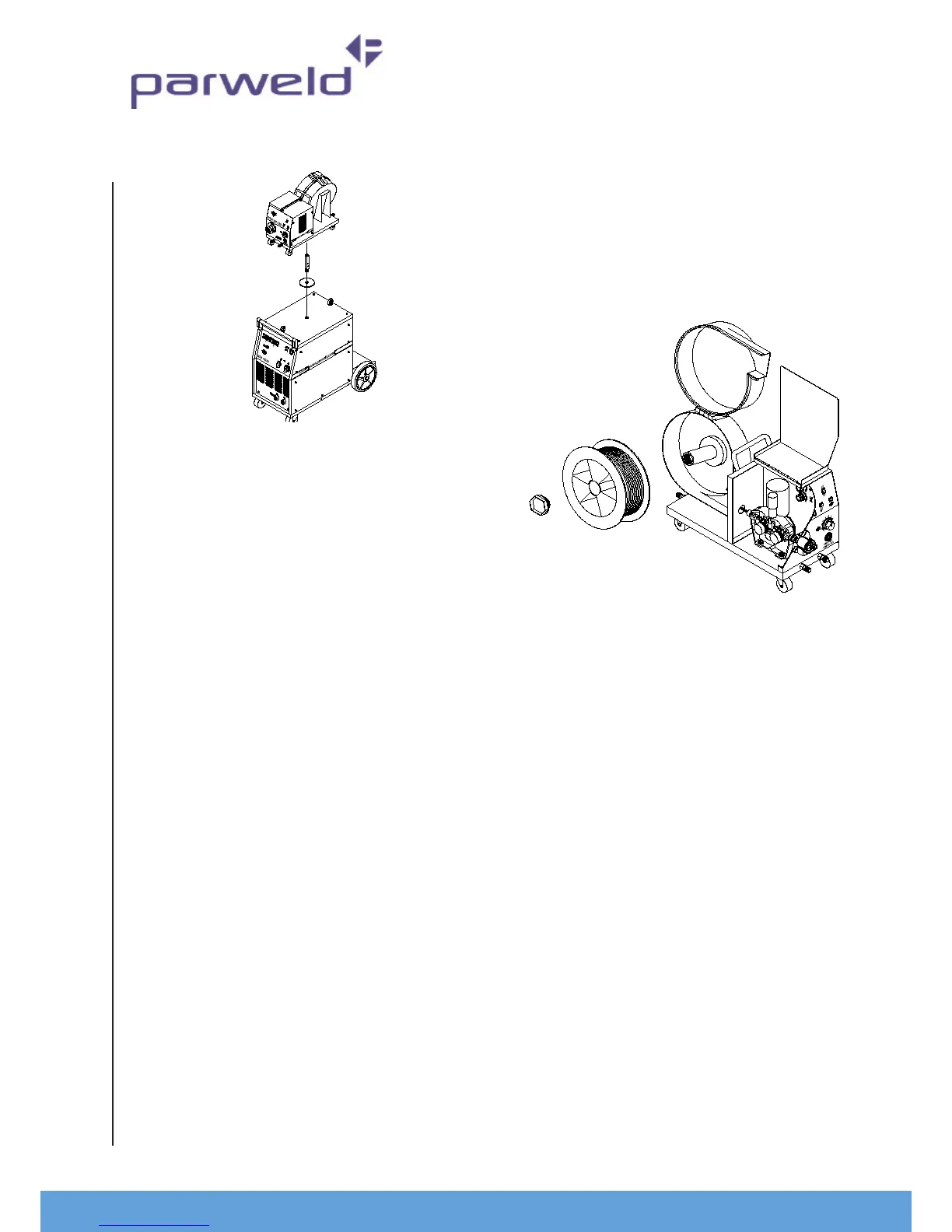

5.4 Assembly of Separate wire feeder

Note:- if the wire feeder is going to be used remotely

to the power source there is not need to assemble the

mounng post.

If the wire feeder is to be used local to the power

source.

Place the at chrome disc over the hole in the top of

the power source lid . Insert the threaded chrome

post thread end rst through the at disc and screw

Loading...

Loading...