XTM WF100

4T

2T

10

8

9

2

1

4

PUSH PULL

CONTROL 4 2 V

16

17

18

19

20

21

7

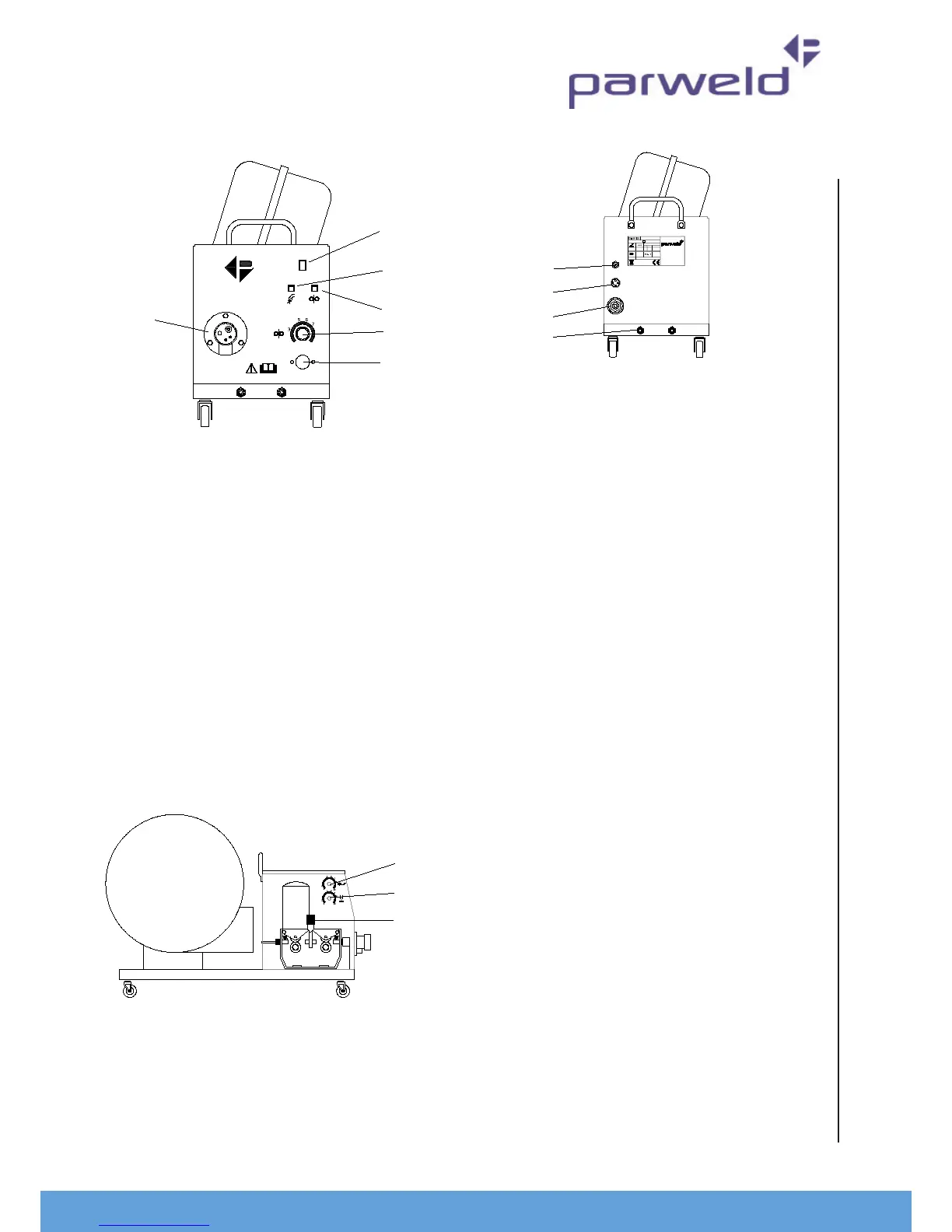

4.0 Descripon of controls

1. Digital display for amperage and Voltage

(displayed real me)

2. Fault light This light will illuminate when a fault or

over temperature condion has occurred. If this

light illuminates allow the machine to cool with

the fan sll running unl it exnguished. If the

light does not go o when the power source has

cooled down then have the machine checked by a

qualied engineer.

3. Mains input light This light illuminates when the

mains power is connected and the machine is

switched on.

4. On O switch. The machine is switched o when

the light (4) is o and the fan is not running.

5. Coarse Voltage selector switch. This switch is used

to select the require welding voltage each posion

of the switch represents approximately 4V.

Do Not operate this switch while welding

6. Fine Voltage selector switch. This switch is used to

select the require welding voltage each posion of

the switch represents approximately 0.5V.

Do Not operate this switch while welding

7. Work return lead connecon. This socket allows

connecon of the work return lead to the front of

the machine.

Note the XTM403S has 2 sockets for the work return

lead please refer below

8. Work return lead connecon. High inductance

connecon, this should be used when in spray

transfer mode to give a more stable arc. (Only

ed to XTM403S)

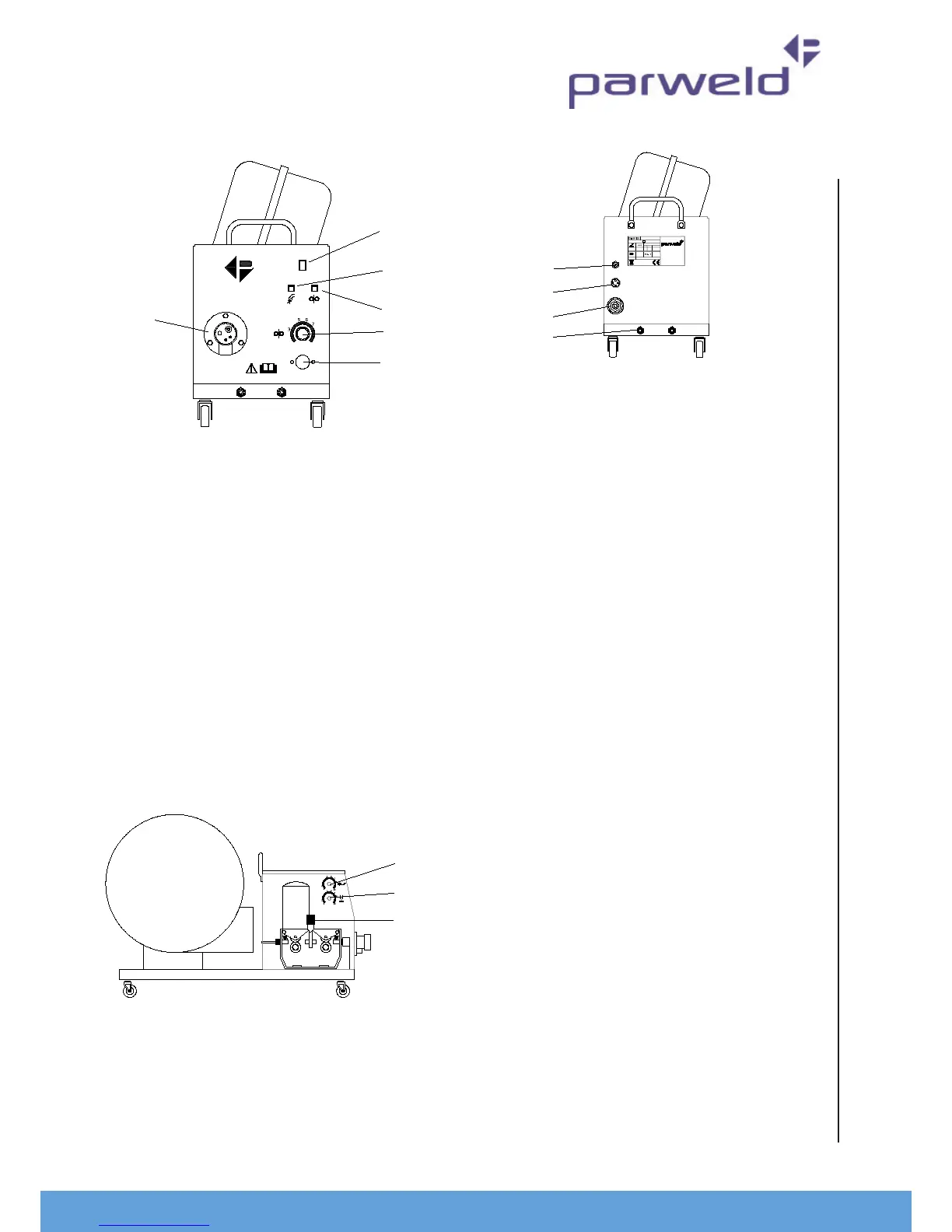

9. Mains input connecon Input connecon for the

pre-installed mains cable

10. Control circuit protecon fuse.

11. Gas cylinder retenon chain to be used when a

gas cylinder is mounted on the rear tray.

12. Auxiliary output. 240V 3A auxiliary output for use

with water cooler or small power tools.

13. Protecon fuse for the Auxiliary output

14. Socket for the interconnecon cable to link to the

wire feeder.

15. Welding power connecon to connect to the inter

connect cable.

16. 2T 4T, when in the 2T posion the torch trigger

will have a momentary operaon ie the welding

operaon will start when the rigger is depressed

and stop when it is released. In the 4T posion a

short press and release of the trigger will start the

welding operaon and a short press and release

with stop the operaon. The 4T mode is ideal for

long welds as it reduces operator fague.

17. Gas purge buon. Pressing this buon allow gas

to ow through the welding torch and so allow

checking of the gas ow before starng the

welding process.

18. Wire inching buon, allows the welding wire to

be fed through the torch without engergising the

welding power.

19. Wire feed speed adjustment, controls the speed of

wire feeding from 0.8 to 24 m/min. Increasing the

wire feed speed also has the eect of increasing

the welding current

20. Locaon for control socket if machine is ed with

Push Pull torch

21. Torch connector The Euro connector provided the

external connecon for the welding torch

9

4

3

9

4

3

22

23

24

60A/17V to 350A/31.5V

X 60% 100%

1 ~50 Hz

U1 = 42V

IP 21 S

Rohs Compliant

ENGLAND.

DY12 2TZ,

WORCESTERSHIRE,

LONG BANK BEWDLEY,

BEWDLEY BUSINESS PARK,

PARWELD LTD,

S No.

ISO/IEC 60974-1

I2 500A 350A

M

I1 eff = A

WIRE FEEDER

CON TRO L

INTERCONNECTING

CAB LE

GAS I NPUT

25

26

27

27

Loading...

Loading...