6

prevent falling or pping. Keep cylinders away from

any welding or other electrical circuits. Never drape

a welding torch over a gas cylinder. Never allow a

welding electrode to touch any cylinder. Never weld

on a pressurized cylinder - explosion will result. Use

only correct shielding gas cylinders, regulators, hoses,

and ngs designed for the specic applicaon;

maintain them and associated parts in good condion.

Turn face away from valve outlet when opening

cylinder valve.

Use the right equipment, correct procedures,

and sucient number of persons to li and move

cylinders.

Read and follow instrucons on compressed gas

cylinders, associated equipment, and Compressed Gas

Associaon (CGA)

2.0 Product Descripon

The XTM 353S and 403S are complete

semiautomac constant voltage DC arc welding

machines built to meet CE specicaons. They

combine a constant voltage power source and a

constant speed wire feeder with a microcomputer-

based controller to form a reliable high-performance

welding system. A simple control scheme, consisng

of a range voltage and wire feed speed controls,

provides versality with ease of use and accuracy.

Other features include separate wire feed unit for

remote operaon, an integral gas cylinder mounng

undercarriage, an adjustable Argon ow regulator

with cylinder pressure gauge and inlet hose, a Parweld

MIG torch, and a 3.0m work cable with clamp.

Digital meters display the actual welding voltage and

amperage and the machine has addional controls for

adjustment of burn back and so starng.

3.0 Technical Specicaons

The XTM353S and 403S are a separate type machine

with the wire feed unit connected to the power supply

but a 5m interconnecng cable for use with 3 phase

400V supply.

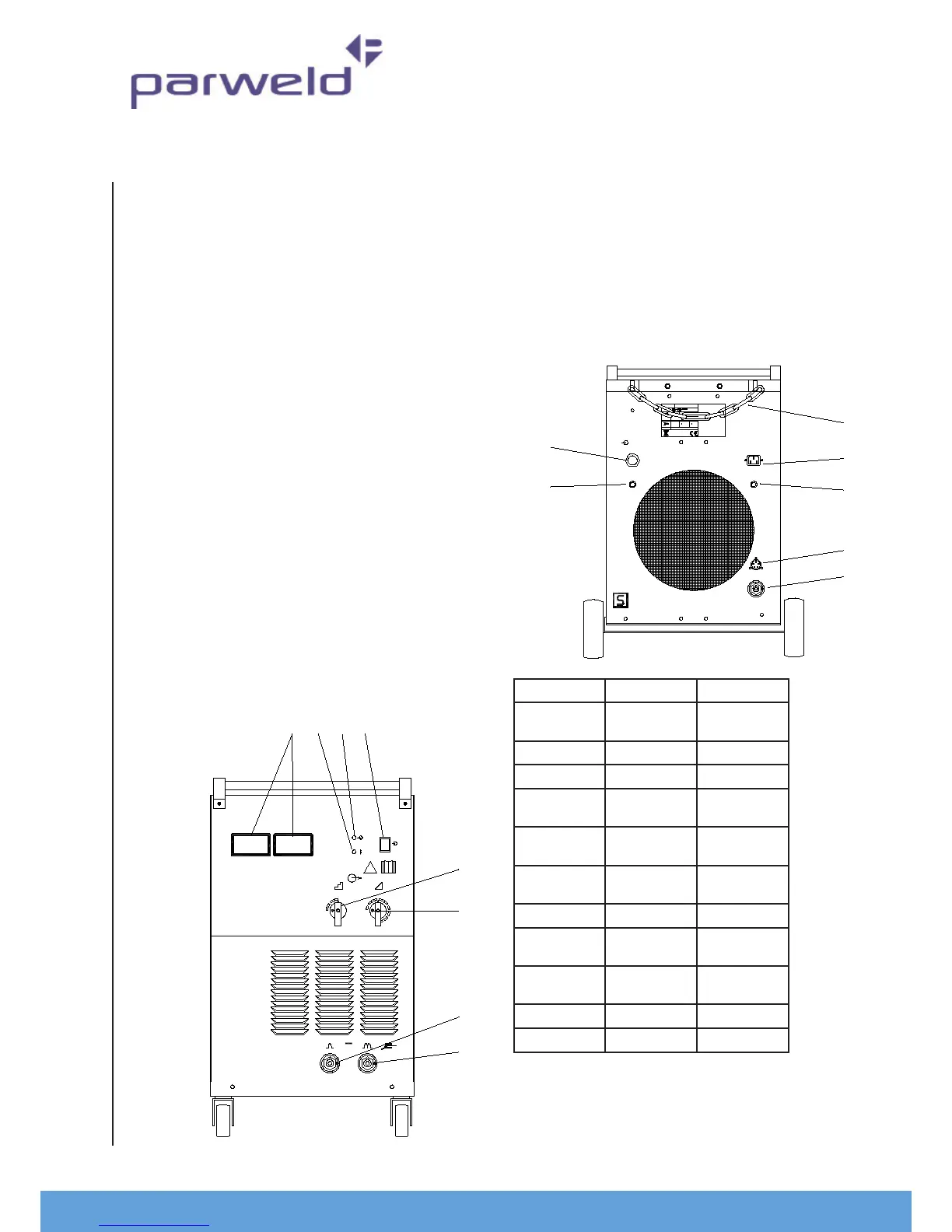

Feature XTM353S XTM403S

Input

voltage

400V +/-

10%

400V +/-

10%

Hz 50 50

Phases 3 3

Current

Draw (A)

13 14

Fuse rang

(A)

16 25

Output

current (A)

50-250 60-350

OCV 18-36 20-45

Load

voltage

16.5-26.5 17-31.5

Feed speed

m/min

0.8-24 0.8-24

Feed motor 42V 42V

Wire drive 4 roll 4 roll

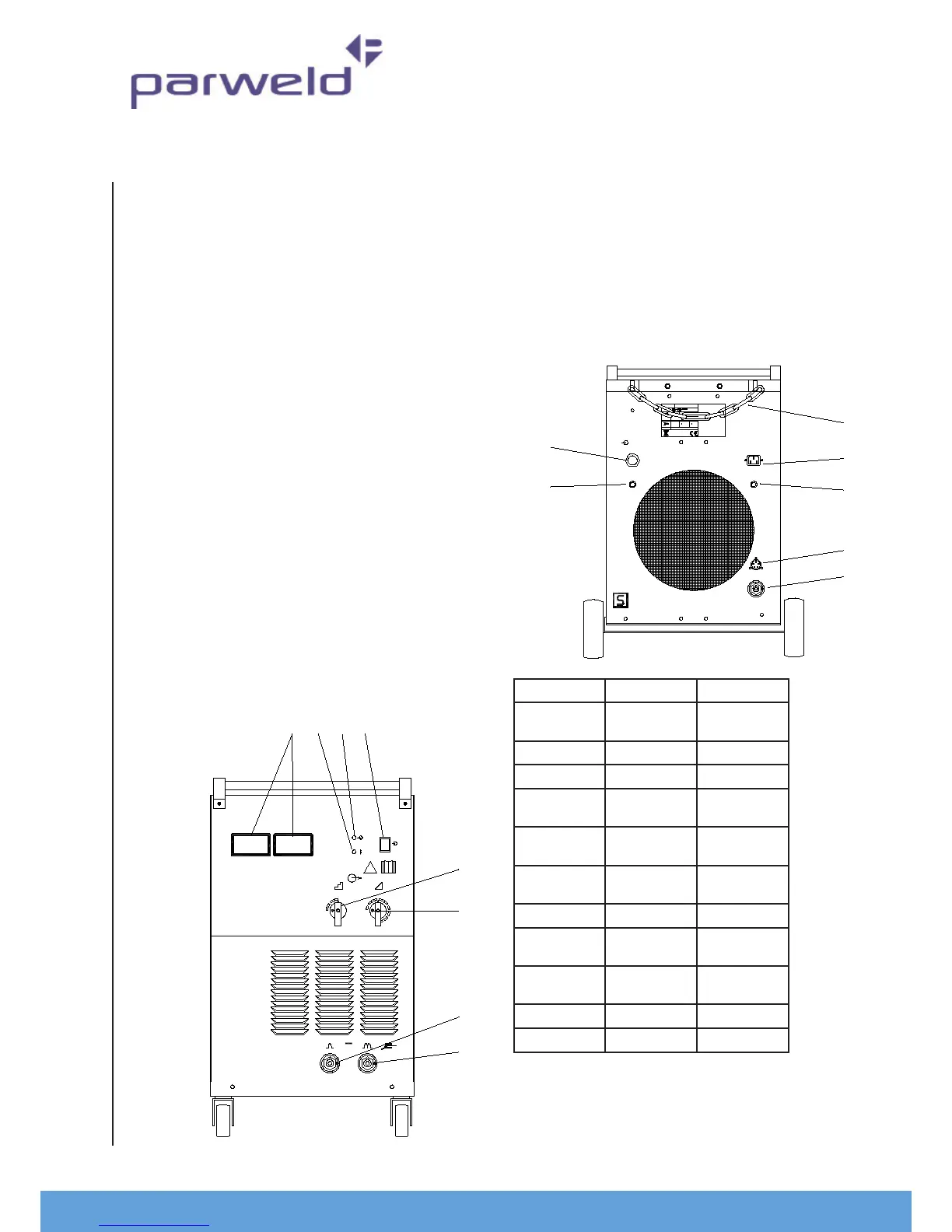

1 2

3 4

5

6

7

8

9

8

7

6

4

5

1

2

3

A

B

C

1

V

!

0

V A

XTM 403S

V

V

9

11

12

14

15

WIRE

FEEDER

INTERCONNECTING PLUG

WIRE FEEDER

8A

CONTROL

CIRCU IT

AUX 230V 1P

V

3P -400V

8A

ISO/IEC 60974-1

3 ~50 Hz

U0= 20~42V

U1 = 400v

I max =23A

I eff =16 A

IP 21S

Rohs Compliant

ENGLAND.

DY12 2TZ,

WORCESTERSHIRE,

LONG BANK BEWDLEY,

10

13

Loading...

Loading...