3

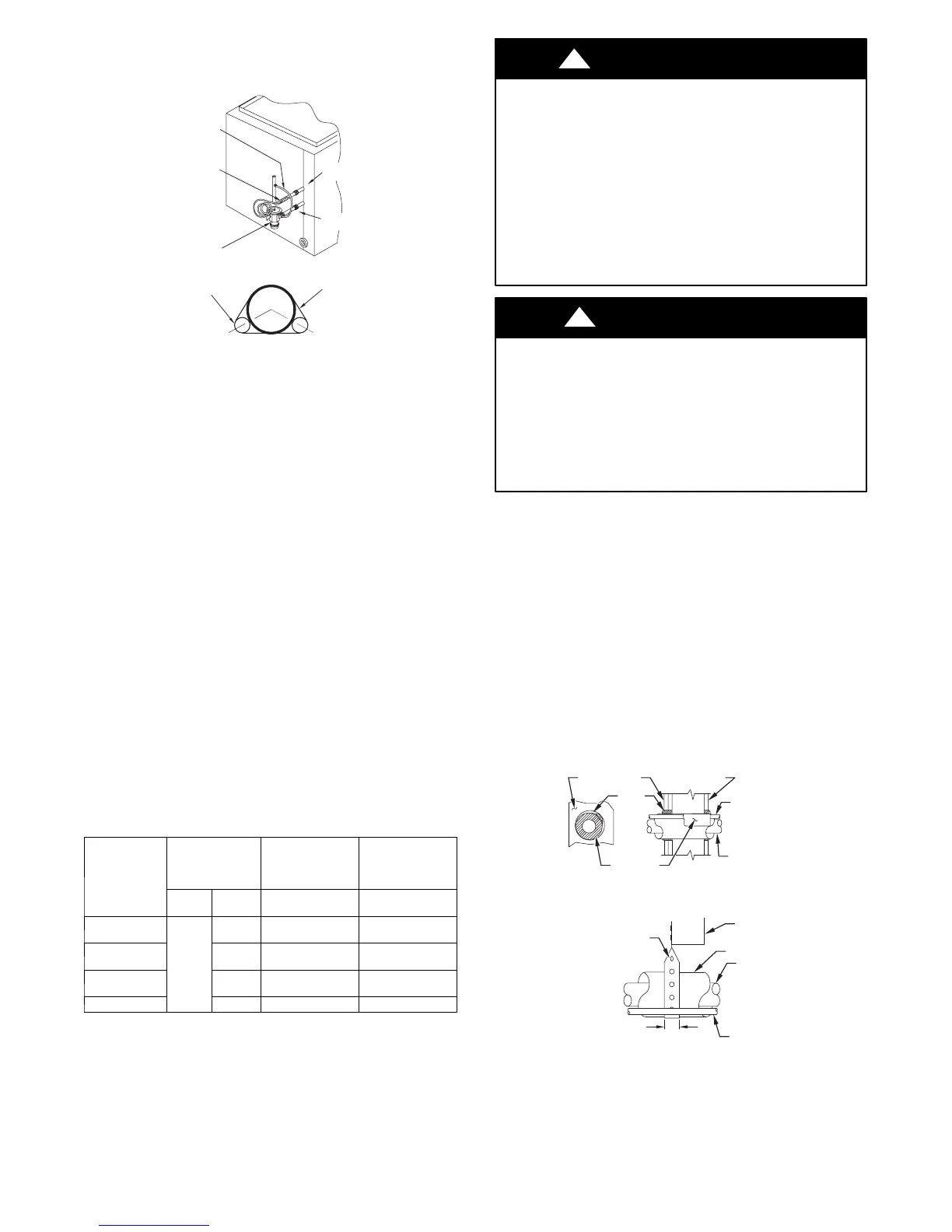

When installing a hard shut--off TXV on an indoor coil, follow the

instructions provided with the new TXV.

A typical hard shut--off TXV installation is shown in Fig. 2.

HARD

SHUT OFF

TXV

SENSING

BULB

EQUALIZER

TUBE

8 O’CLOCK 4 O’CLOCK

STRAP

SENSING BULB

(EITHER SIDE)

SUCTION

TUBE

INDOOR

COIL

SUCTION

TUBE

LIQUID

TUBE

A07587

Fig. 2 --- T ypical TXV Installation

B. REFRIGERANT LINE SETS

The refrigerant line set must be properly sized to assure maximum

efficiency and proper oil circulation. Select line set tube diameters

as specified in Table 1.

NOTE: Total line set length must not exceed 200 feet (61 m).

NOTE: A crankcase heater must be used when the refrigerant line

length exceeds 80 feet (24 m).

If outdoor unit is more than 10 feet (3 m) higher than the indoor

coil, refer to the Extended Length Refrigeration Piping Manual for

instructions.

NOTE: When the outdoor unit is higher than the indoor coil, the

vertical separation must not exceed 100 feet (31 m).

NOTE: When the outdoor unit is lower than the indoor coil, the

vertical separation must not exceed 50 feet (15 m).

If it is necessary to add refrigerant line in the field, use dehydrated

or dry, sealed, deoxidized, copper refrigeration tubing. Do not use

copper water pipe.

Do not remove rubber plugs or caps from copper tubing until

connections are ready to be made.

Be extra careful when bending refrigeration tubing. Tubing can

“kink” easily, and if this occurs, the entire length of tubing must be

replaced.

Table 1—R -- 410A Line Set Tube Diameter

(Liquid Tube Always 3/8” Dia.)

MODEL SIZE

SERVICE VAL VE

FITTINGS

(IN.)

LINE SET

< 80 FEET

(24 M) LONG

LINE SET

80 --- 200 FEET

( 2 4 --- 6 1 M )

LONG

Liquid Suction

Suction Line

Diameter

Suction Line

Diameter (in.)

18 (12 ton)

24 (2 ton)

3/8

5/8 5/8 3/4

30 (22 ton)

36 (3 ton)

3/4 3/4 7/8

42 (32 ton)

48 (4 ton)

7/8 7/8 1 --- 1 / 8

60 (5 ton) 7/8 1 --- 1 / 8 1 --- 1 / 8

NOTE: If the line set length exceeds 80 f eet (24 m), also refer to L on g Line

Application Guide for additional information.

PERSONAL INJURY and ENVIRONMENTAL

HAZARD

Failure to relieve system pressure could result in personal

injury and/or death.

1.Relieve pressure and recover all refrigerant before

servicing existing equipment, and before final unit

disposal. Use all service ports and open all flow--control

devices, including solenoid valves.

2.Federal regulations require that you do not vent refrigerant

into the atmosphere. Recover during system repair or

final unit disposal.

!

WARNING

UNIT OPERATION HAZARD

Failure to follow this caution may result in improper

product operation.

Do not leave system open to atmosphere any longer than

absolutely required for installation. Internal system

components -- especially refrigerant oils -- are extremely

susceptible to moisture contamination. Keep ends of tubing

sealed during installation until the last possible moment.

CAUTION

!

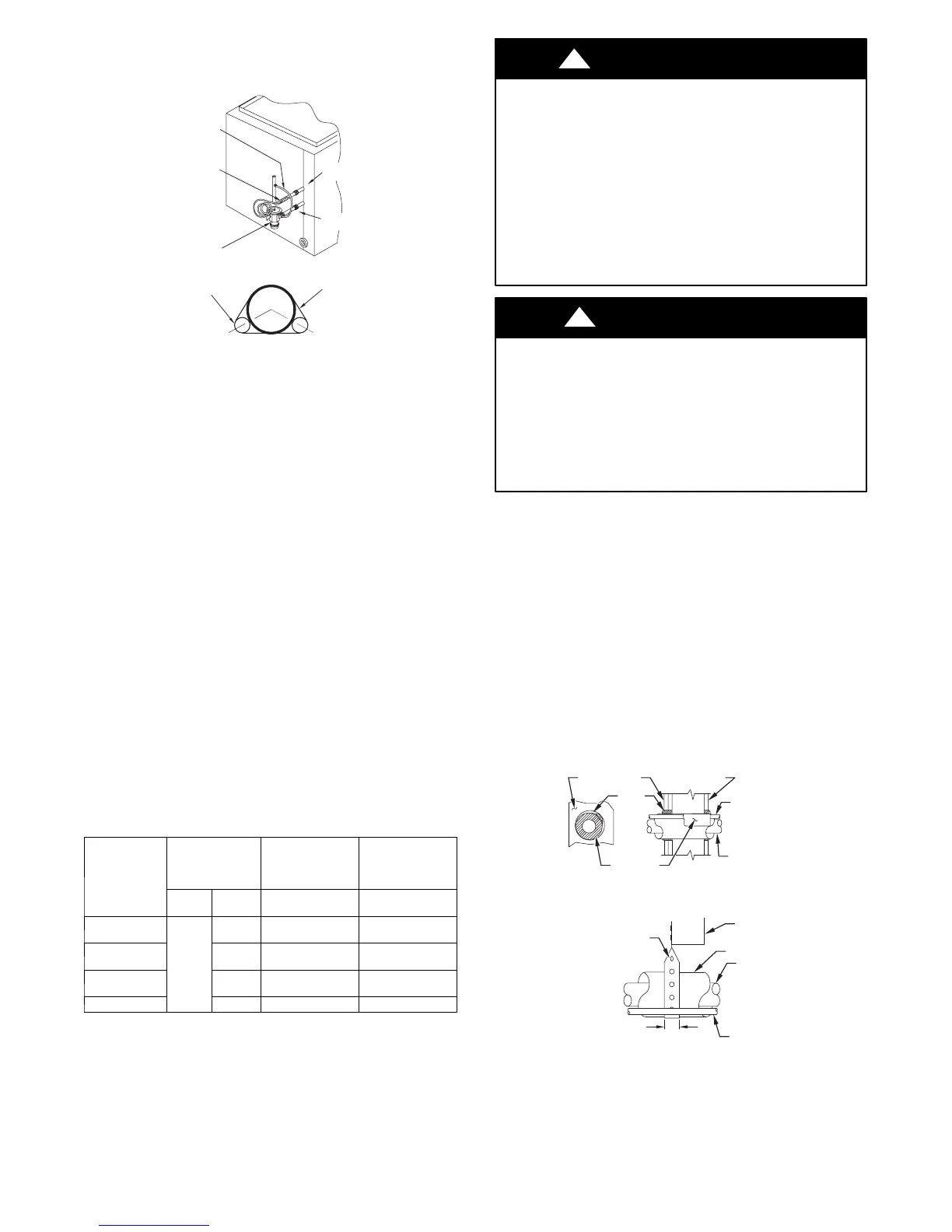

C. ROUTING AND SUSPENDING REFRIGERANT LINES

Run refrigerant lines as straight and direct as possible, avoiding

unnecessary bends and turns. Always insulate the entire suction

line. Both lines should be insulated when routed through an attic or

when routed through an underground raceway.

When routing refrigerant lines through a foundation or wall, do not

allow refrigerant lines to come in direct contact with the building

structure. Make openings large enough so that lines can be

wrapped with extra insulation. Fill all gaps with RTV caulk. This

will prevent noise transmission between the tubing and the

foundation or wall.

Along floor or ceiling joists, suspend refrigerant lines so that they

do not contact the building structure, water pipes, or ductwork. Use

insulated or suspension type hangers. Metal straps must be at least

1” (25 mm) wide to avoid cutting into the tube insulation. Keep the

liquid and suction lines separate. Refer to Fig. 3.

INSULATION

SUCTION TUBE

LIQUID TUBE

OUTDOOR WALL INDOOR WALL

LIQUID TUBE

SUCTION TUBE

INSULATION

CAULK

HANGER STRAP

(AROUND SUCTION

TUBE ONLY)

JOIST

1” MIN

THROUGH THE WALL

SUSPENSION

A07588

Fig. 3 --- Routing and Suspending Refrigerant Lines

Loading...

Loading...