4

UNIT OPERATION HAZARD

Failure to follow this caution may result in improper

product operation.

Do not bury more than 36” (914 mm) of line set

underground. Refrigerant may migrate to cooler buried

section during extended periods of unit shut-- down, causing

refrigerant slugging and possible compressor damage at

start--up.If ANY section of the line set is buried

underground, provide a minimum 6” (152 mm) vertical rise

at the service valve.

CAUTION

!

D. OUTDOOR UNIT HIGHER THAN INDOOR UNIT

Proper oil return to the compressor should be maintained with

suction gas velocity. If velocities drop below 1500 fpm (feet per

minute), oil return will be decreased. To maintain suction gas

velocity , do not upsize vertical suction risers. Use the “<80 feet (24

m)” suction line sizes shown Table 1.

Install oil traps every 20 feet (6 m) of vertical suction line riser .

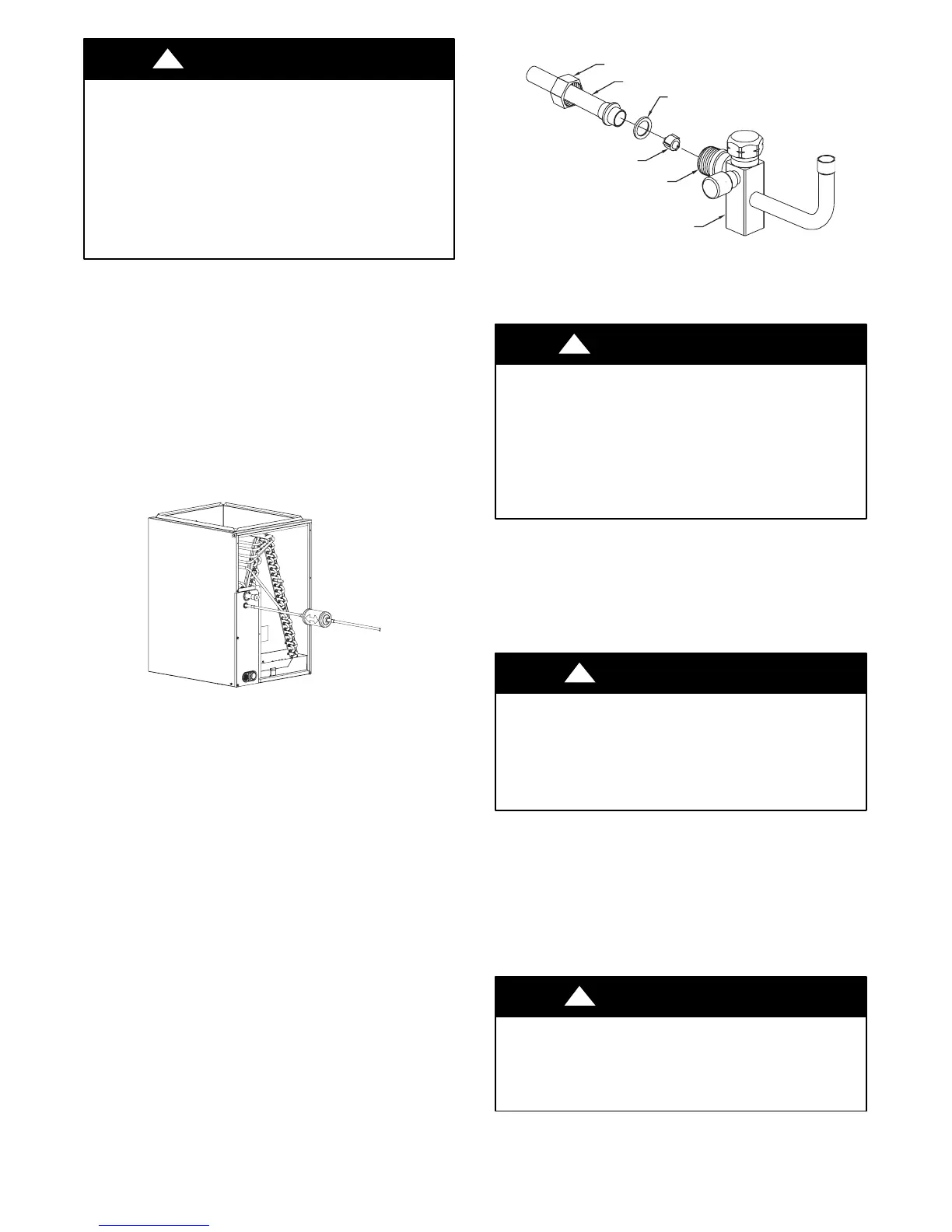

E. LIQUID LINE FILTER --DRIER

Outdoor units are shipped with an appropriate filter--drier for

installation in the liquid line. Leave the plugs in the tube ends until

the filter--drier is installed. The optimal location for the filter--drier

is close to the indoor coil. Install the filter--drier with the arrow

pointing towards the indoor coil. Refer to Fig. 4.

A05227

Fig. 4 --- Liquid Line Filter Drier Installed at Indoor Coil

F. SERVICE VALVES

Service valves are closed and plugged from the factory. Outdoor

units are shipped with a refrigerant charge sealed in the unit. Leave

the service valves closed until all other refrigerant system work is

complete or the charge will be lost. Leave the plugs in place until

line set tubing is ready to be inserted.

Heat pumps require a piston metering device in the liquid service

valve for proper heating operation. Piston is shipped in the piston

body of the liquid service valve, temporarily held in place with a

plastic cap. Do not remove the plastic cap until line set tubing is

ready to be installed.

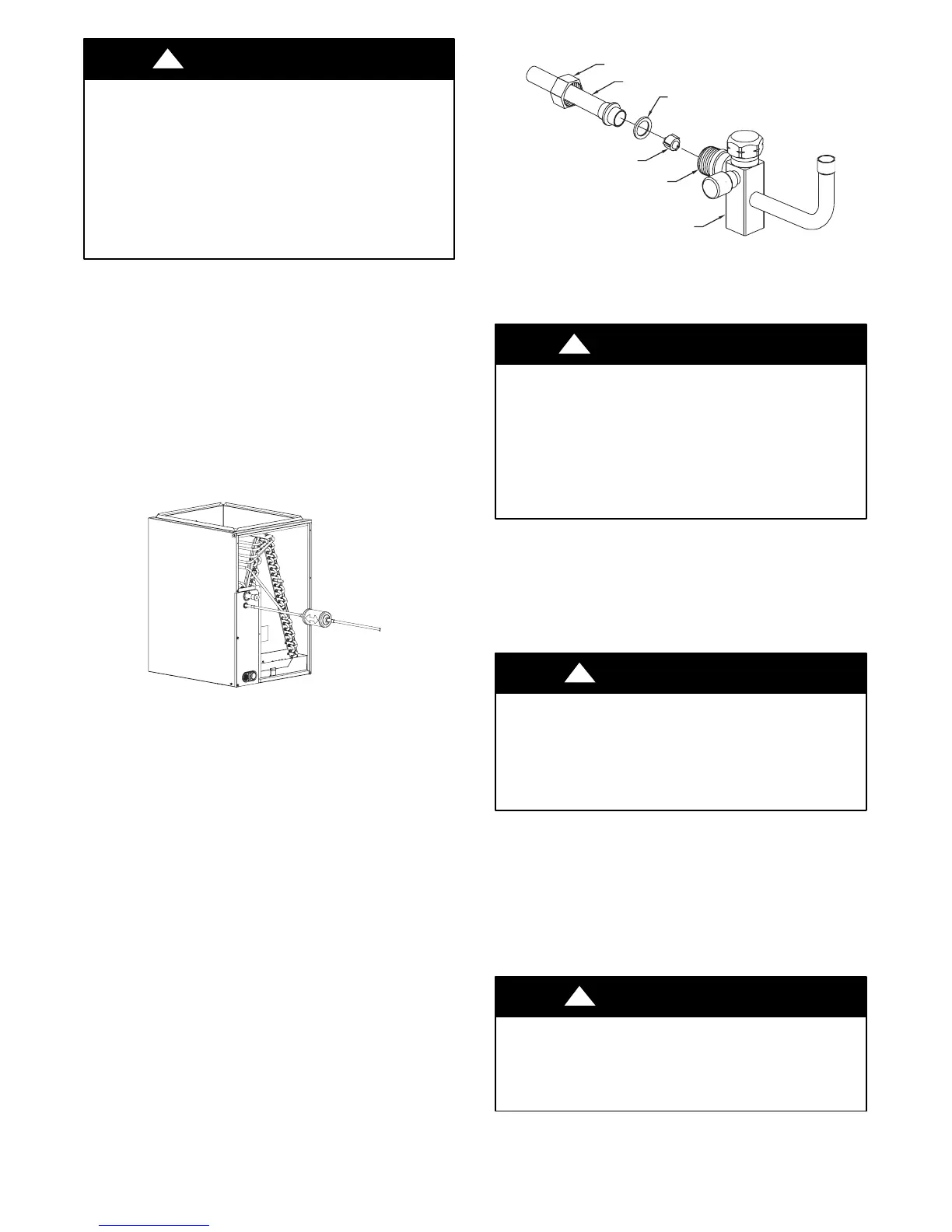

Refer to Fig. 5 and follow these steps for piston installation:

1. Remove plastic cap holding piston in piston body of liquid

service valve.

2. Check that piston size (stamped on side of piston) matches

with number listed on unit rating plate. Return piston to

piston body of liquid service valve (either direction).

3. Find plastic bag taped to unit containing copper adapter

tube, brass nut, and plastic washer.

4. Install plastic washer in the seat inside piston body.

5. Fit brass nut onto adapter tube and install tube onto liquid

service valve. Tighten nut finger tight, then wrench

additional half turn only. Over tightening may damage the

plastic washer.

Service valve bodies are brass and suction tube stub is copper.

PISTON BODY

LIQUID SERVICE VALVE

PISTON

PLASTIC WASHER

ADAPTER TUBE

BRASS NUT

A07594

Fig. 5 --- Liquid Service Valve with Piston and Adapter Tube

G. BRAZING CONNECTIONS

FIRE HAZARD

Failure to follow this warning could result in personal injury,

death, and/or property damage.

Refrigerant and oil mixture could ignite and burn as it

escapes and contacts brazing torch. Make sure the refrigerant

charge is properly removed from both the high and low sides

of the system before brazing any component or lines.

!

WARNING

Clean line set tube ends with emery cloth or steel brush. Remove

any grit or debris.

Insert line set tube ends into service valve tube stubs.

Apply heat absorbing paste or heat sink product between service

valve and joint. Wrap service valves with a heat sinking material

such as a wet cloth.

Braze joints using a Sil--Fos or Phos--copper alloy.

PRODUCT DAMAGE HAZARD

Failure to follow this caution may result in product damage.

Braze with Sil--Fos or Phos--copper alloy on

copper--to--copper joints and wrap a wet cloth around rear

of fitting to prevent damage to TXV.

CAUTION

!

H. EVACUATING LINE SET AND INDOOR COIL

The unit is shipped with a factory refrigerant charge. The liquid

line and suction line service valves have been closed after final

testing at the factory. Do not disturb these valves until the line set

and indoor coil have been evacuated and leak checked, or the

charge in the unit may be lost.

NOTE: Do not use any portion of the factory charge for purging

or leak testing. The factory charge is for filling the system only

after a complete evacuation and leak check has been performed.

PRODUCT DAMAGE HAZARD

Failure to follow this caution may result in product damage.

Never use the outdoor unit compressor as a vacuum pump.

Doing so may damage the compressor.

CAUTION

!

Loading...

Loading...