Page 54

Ph: 804.227.3023

10511 Old Ridge Rd. Ashland, VA 23005

4LHD/4LHDX Application Manual

Powertrain Control Solutions

REV 1.1

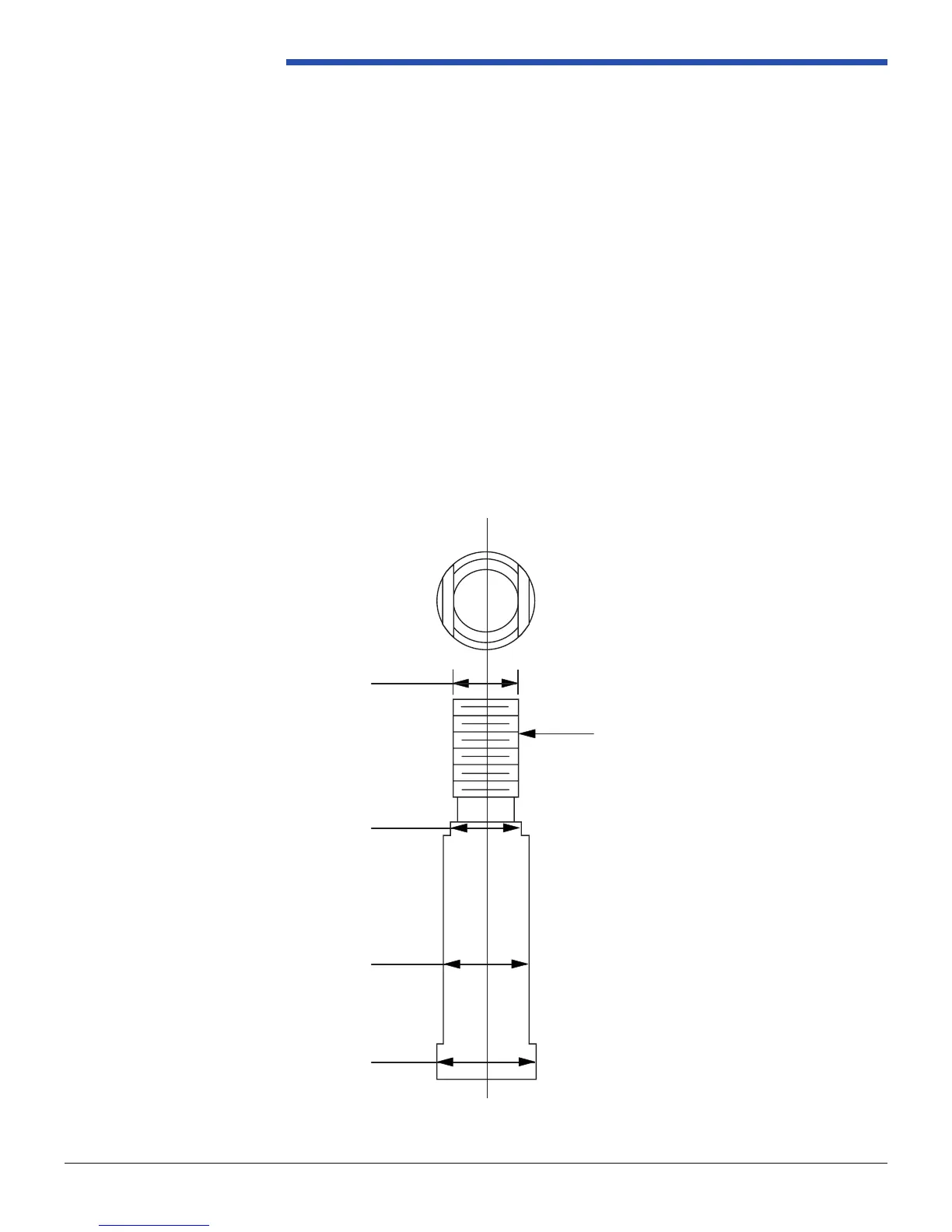

2.4.1 Shaft Specs

The shift lever (which is to be supplied by the vehicle manufacturer) must conform to the following specication:

Stock Thickness: 4.3 to 4.7 mm (0.169 to 0.185 in)

Hardness: Surface le hard Rc 59 min.

Case depth 0.12 to 0.25 mm (0.005 to 0.010 in)

Parts should not be brittle.

Manual shaft connection:

The interface between the manual shaft ats and the lever ats must have a press t of

0.00 to 0.13 mm (0.000 to 0.005 in).

Punch direction must be from the lead-in side.

Slot dimensions to be maintained for a minimum of 50% stock thickness from lead-in side. No burrs permissible around

slot on lead-in side.

Corrosion protection of external nut and lever required to be compatible with coating on

manual shaft.

Figure 2.4.1-1 Manual Shaft Dimension

RevSheet 6924214609

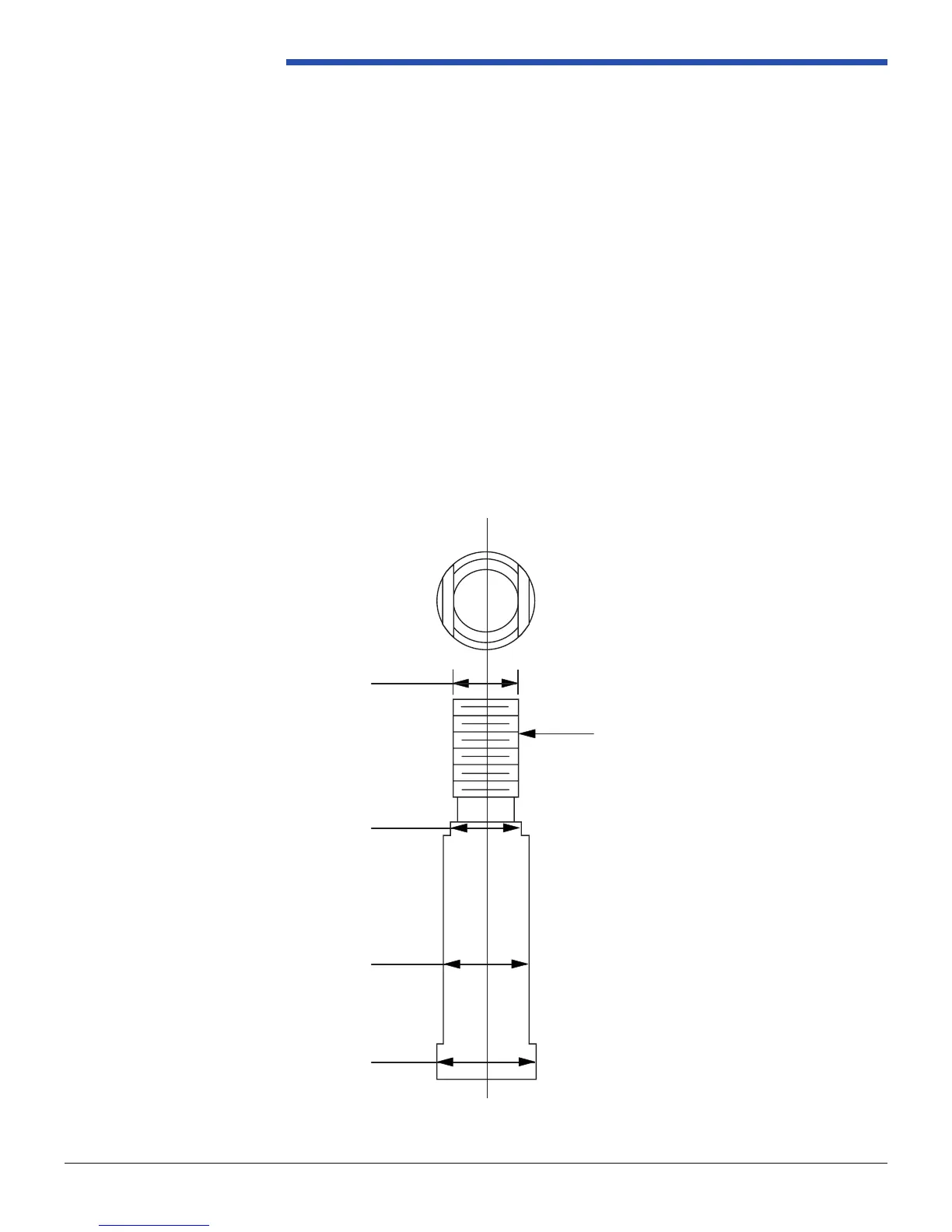

3.4.2. Manual Shaft/Lever Interface

The shift lever (which is to be supplied by the vehicle assembly division) must conform to

the following specification:

Stock Thickness: 4.3 to 4.7 mm (0.169 to 0.185 in)

Hardness: Surface file hard Rc 59 min.

Case depth 0.12 to 0.25 mm (0.005 to 0.010 in)

Parts should not be brittle.

Manual shaft connection:

The interface between the manual shaft flats and the lever flats must have a press fit of

0.00 to 0.13 mm (0.000 to 0.005 in).

Punch direction must be from the lead-in side.

Slot dimensions to be maintained for a minimum of 50% stock thickness from lead-in side.

No burrs permissible around slot on lead-in side.

Corrosion protection of external nut and lever required to be compatible with coating on

manual shaft.

FIGURE 3.4.2-1 Manual Shaft Dimension

M10 x 1.5-6g

8.05 ± 0.13

10.90 ± 0.04

12.677 ± 0.010

8.40 ±

0.03

0.02

Loading...

Loading...