When servicing or replacing components, be

absolutely certain that the following conditions are

met:

• Water, gas and electricity are off.

• The boiler is at room temperature.

• There is no pressure in the boiler.

OUTE ON i

// [)ARK BL JL //_\

IN CC' OR , /

1. Check flueways and burners for cleanliness and dean

if necessary. Use the following procedure if cleaning

is required:

a. Refer to the Lightin_Operating Instructions in

Figures 25 and 26 to properly turn off the gas to

the boiler.

b. Turn off all electrical power to the boiler.

c. Remove burners and brush gas outlet ports

lightly using a soft bristle brush.

d. Remove the vent pipe, vent damper, top jacket

panels and flue collector/draft diverter. Remove

baffles on MIH models.

e. Brush flueways with wire brush.

To the extent possible, inspect inside of vent pipe

and vent damper for obstructions in flow or vent

damper movement. Remove or replace as

necessa[v.

g.

Re-install baffles on MIH models. When replacing

the flue collector/draft hood, be certain that the

blanket seal between the flue collector and top

section makes a tight seal to prevent leakage of

the products of combustion.

h. Re-install the top of the jacket, vent damper and

vent pipe.

i. Re-install burners.

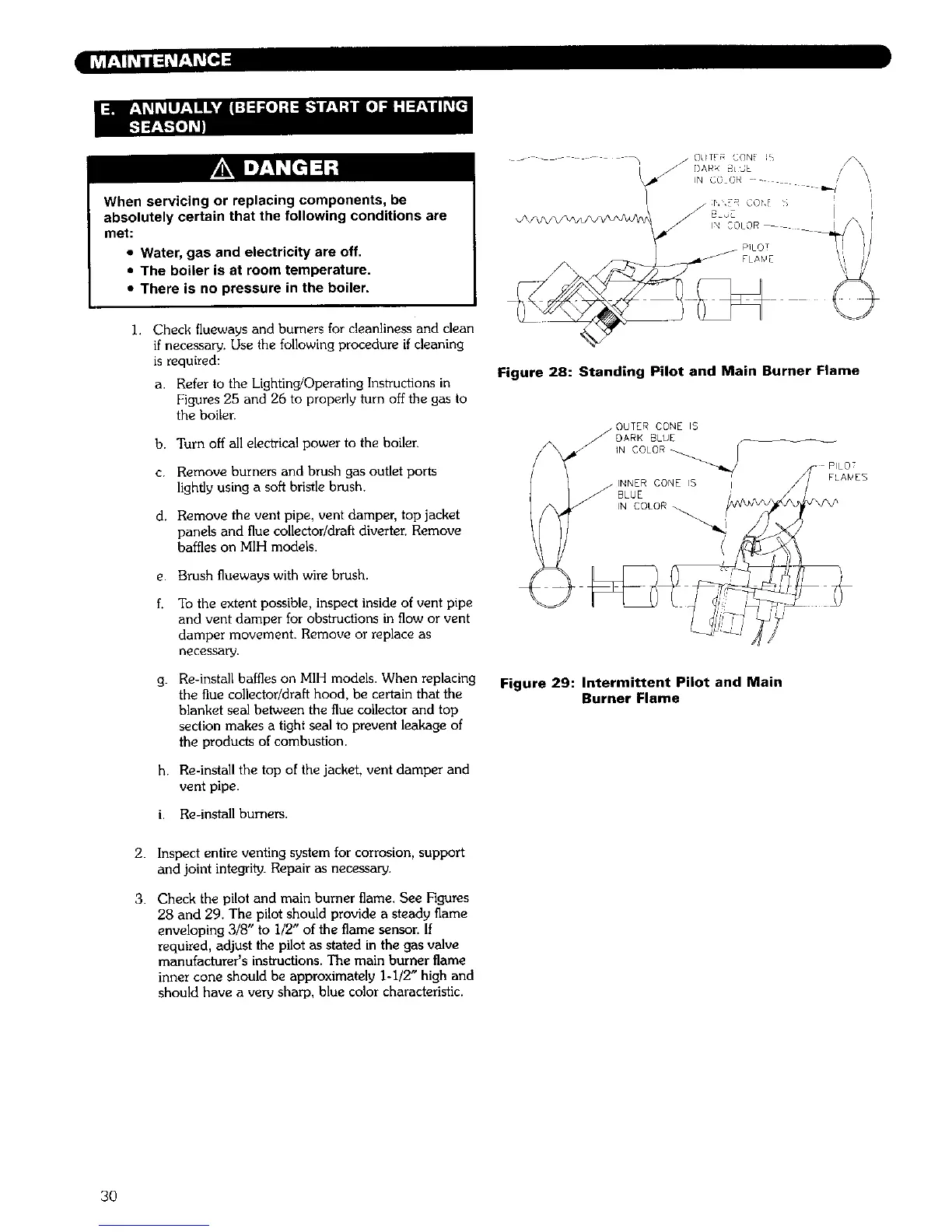

Figure 28: Standing Pilot and Main Burner Flame

INNER CONE IS

BLUE

IN COLOR

FLA_EB

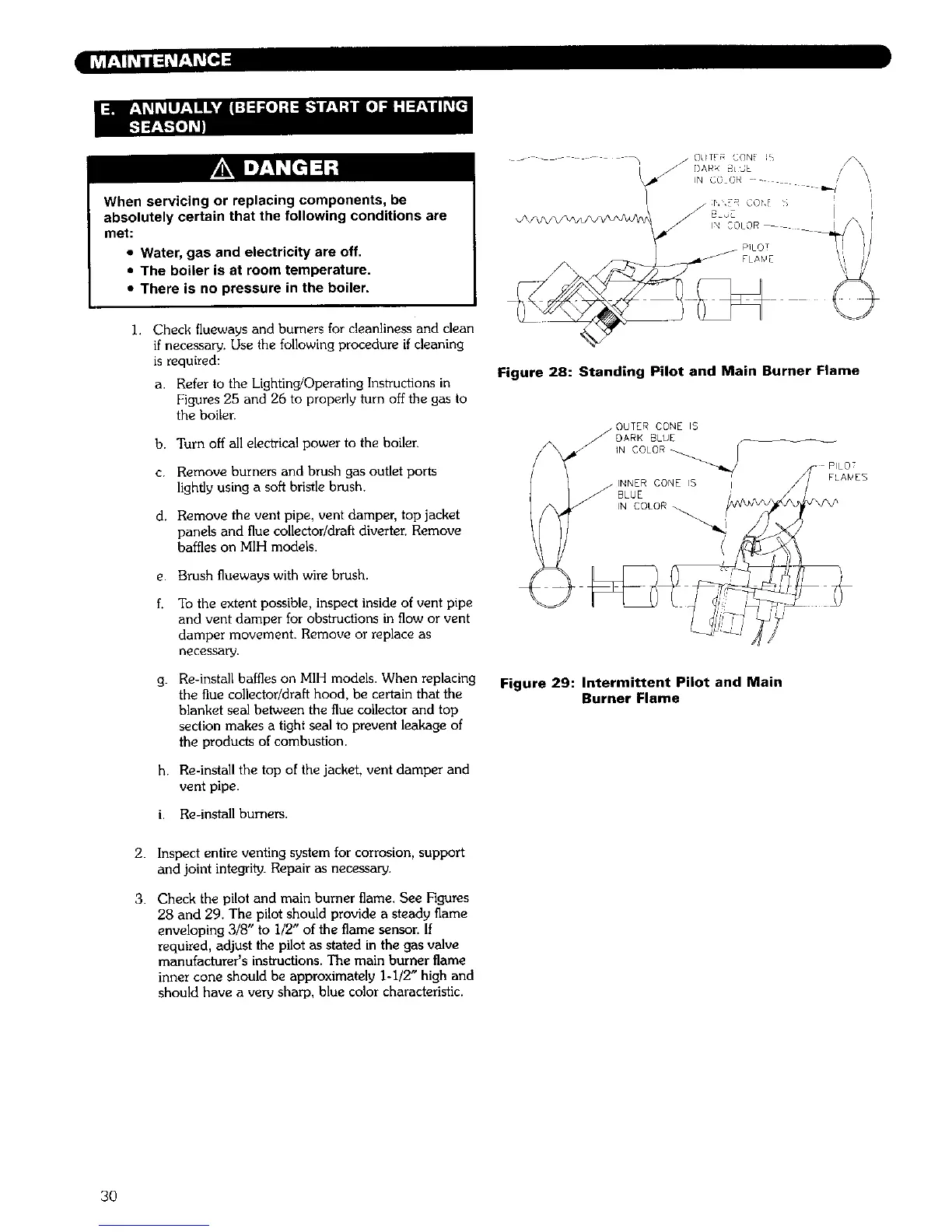

Figure 29: Intermittent Pilot and Main

Burner Flame

2.

3.

Inspect entire venting system for corrosion, support

and joint integrity. Repair as necessary.

Check the pilot and main burner flame. See Figures

28 and 29. The pilot should provide a steady flame

enveloping 3/8" to i/2" of the flame sensor. If

required, adjust the pilot as stated in the gas valve

manufacturer's instructions. The main burner flame

inner cone should be approximately 1-1/2" high and

should have a very sharp, blue color characteristic.

3O

Loading...

Loading...