Ill mY4 =lb.'Hai I:JI'.,l::i iL__"]aW-'IHIar-"aai[o] K_

1.

2.

3.

r_,qI:il I_I al::liaid".JI:,J_ IIk_[,.-'11ir_,1nar_,'aiI[,] _

4,

For minimum and maximum vent pipe lengths see

Table 1

Use only 3" diameter Heat Fab Saf-T Vent, Z-Flex

Z V_nt, ProTech FasNSeaL or Flex L Star-34 Type

AL2.9-4C stainless steel vent pipe and fittings for

venting of flue gases from the boiler.

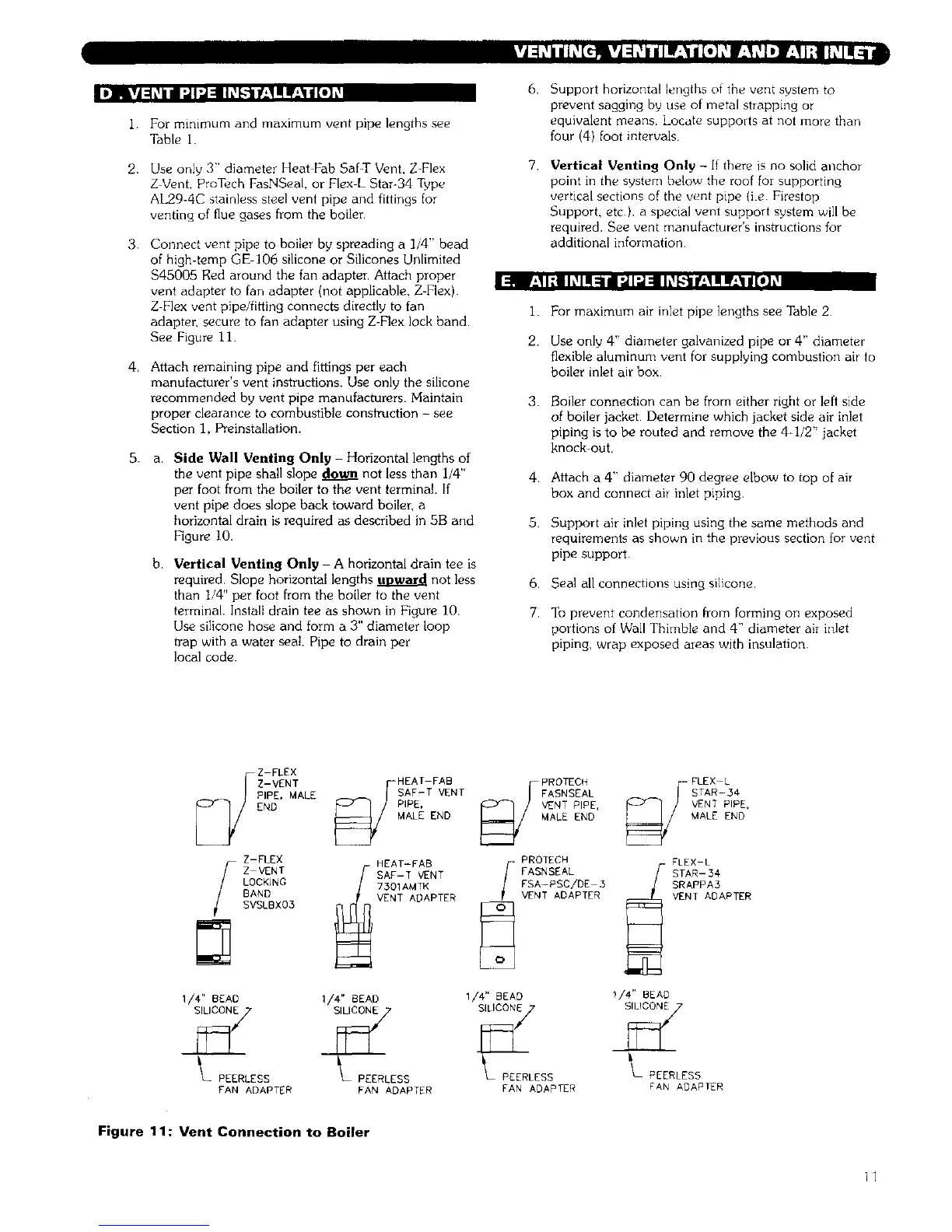

Connect vent pipe to boiler by spreading a I/4" bead

of high-temp GE 106 silicone or Silicones Unlimited

$45005 Red around the fan adapter. Attach proper

vent adapter to fan adapter (not applicable, Z-Flex)

Z-Flex vent pipe/fiRing connects directly to fan

adapter, secure to fan adapter using Z-Flex lock band.

See Figure 11.

Attach remaining pipe and fittings per each

manufacturer's vent instructions. Use only the silicone

recommended by vent pipe manufacturers. Maintain

proper clearance to combustible construction - see

Section 1, Preinstallation.

5. a,

b,

Side Wall Venting Only - Horizontal lengths of

the vent pipe shall slope down not less than 1/4"

per foot from the boiler to the vent terminal. If

vent pipe does slope back toward boiler, a

horizontal drain is required as described in 5B and

Figure 10.

Vertical Venting Only - A horizontal drain tee is

required. Slope horizontal lengths ._ not less

than I/4" per foot from the boiler to the vent

terminal. Install drain tee as shown in Figure I0.

Use silicone hose and form a 3" diameter loop

trap with a water seal. Pipe to drain per

local code.

6.

Support horizontal l_,ngths of the vent system to

prevent sagging by use of metal strapping or

equivalent means. Locate supports at not more than

four (4) foot intervals

Vertical Venting Only - If there is no solid anchor

point in the system below the roof for supporting

vertical sections of the vent pipe fie Firestop

Support, etc.), a special vent support system will be

required. See vent manufacturer's instructions for

additional information

1.

2.

3.

4.

5.

6.

7.

For maximum air inlet pipe lengths see Table 2

Use only 4" diameter galvanized pipe or 4" diameter

flexible aluminum vent for supplying combustion air to

boiler inlet air box.

Boiler connection can be from either right or left side

of boiler jacket Determine which jacket side air inlet

piping is to be routed and remove the 4-1/2" jacket

knock out.

Attach a 4" diameter 90 degree elbow to top of air

box and connect air inlet piping.

Support air inlet piping using the same methods and

requirements as shown in the previous section for vent

pipe support.

Seal all connections using silicone.

To prevent condensation from forming on exposed

portions of Wall Thimble and 4" diameter air inlet

piping, wrap exposed aleas with insulation.

Z-FLEX

Z-VENT

MALE

Z-FLEX

Z VENT

LOCKING

BAND

SVSLBXO3

HEAT-FAB

SAF-T VENT

PIPE,

MALE END

HEAT-FAB

_ AF-T VENT

7301AMTK

VENT ADAPTER

PROTECH

FABNSEAL

VENT PIPE

MALE END'

FLEX-L

- STAR-34

VENT PIPE

MALE END'

PROTECH FLEX-L

I FASNSEAL _ STAR-54

FSA-PSC/DE 3 SRAPPA3

VENT ADAPTER VENT ADAPTER

1/4" BEAD 1/4" BEAD 1/4" BEAD !/4" BEAD

LREEB E LPER E B

AOA TEBAOAPTERAOA ' R ABA TER

Figure 1 1: Vent Connection to Boiler

11

Loading...

Loading...