5

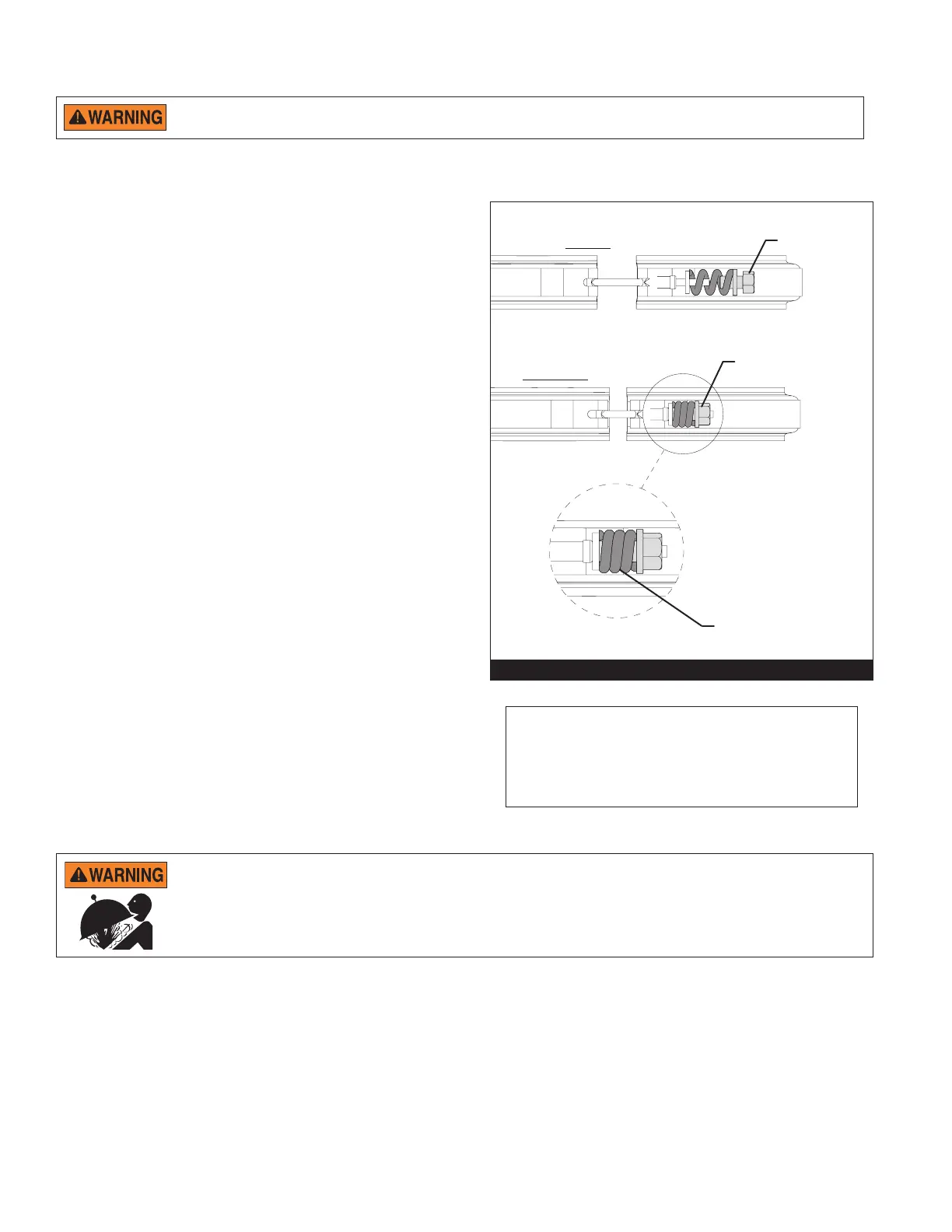

Note: Check the spring coils at least once a

month to ensure proper tension. If spring coils

do not touch then shut o pump and relieve

pressure and tighten the nut and tap lter clamp

until the coils touch.

Reinstalling the Filter Lid and Clamp Ring

RECOMMENDED EQUIPMENT:

• Socket Wrench

• 7/8-inch Socket

• Socket Extender (if needed)

• Rubber Mallet

PROCEDURE:

1. Ensure the O-ring is clean and properly seated on the

tank bottom. Seat the lter lid onto the tank bottom so

the O-ring ts in between the tank halves.

2. Hold the ends of the clamp ring apart and place over

both upper and lower tank anges. Bring the ends of

the lter clamp together.

3. Insert the T-bolt through the other side of the clamp and

hold together.

4. Place the small washer onto the T-bolt.

5. Place the spring, large washer and barrel nut onto the

T -bolt and tighten the nut by hand. Ensure the clamp

ring ts easily on the tank anges.

6. After tightening by hand:

a. Use a 7/8-inch socket wrench to tighten further.

b. Tap around the entire clamp ring with a rubber

mallet (or similar tool) multiple times to t the

clamp properly.

c. Continue to tighten until the spring coils touch.

d. Tap around the entire clamp again and verify the

spring coils remain touching. If not, continue to

tighten the nut.

Note: The clamp is installed correctly only when the

spring coils remain touching after tapping the clamp. See

FIGURE 6.

7. Close the drain plug at the bottom of the lter.

8. Follow Start-Up Instructions, page 6 exactly.

Follow these instructions exactly to prevent the lid from separating from the lter during system start-up or operation.

DO NOT tighten the nut or attempt to adjust the clamp ring or lid while the system is turned on or under pressure. This could

cause the lid to separate from the lter.

TIGHTEN WITH

7/8" WRENCH

HAND TIGHTEN

ONTO T-BOLT

SPRING COILS

TOUCHING

FIGURE 6

CLAMP RING,

OPEN POSITION

CLAMP RING,

CLOSED POSITION

Loading...

Loading...