- 4 -

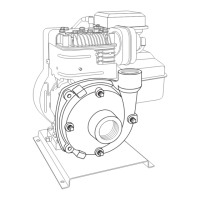

Direct Drive - Flange Mount Installation

GAS ENGINE MOUNT — Model 9513P fits most 5 hp

gas engines with flange mount and 3/4” shaft.

To install pump onto gas engine, first apply anti-seize

compound to gas engine shaft and to inside of pump

hollow shaft. Insert key into engine shaft. Next, slide

pump onto engine shaft and secure with four hex head

bolts. NOTE: Do not force pump onto shaft. Tighten set

screws on pump shaft through slots in flange. Check to

make sure pump rotates freely by slowly turning over the

gas engine.

Operation and Maintenance

IMPORTANT: ENGAGE PTO CLUTCH SLOWLY

AND SMOOTHLY. AVOID SUDDEN STARTS AND

FAST CLUTCHING THAT CAN DAMAGE THE DRIVE

SECTION OF THE PUMPS.

Controlling the Flow

Two flow control valves are used - one in the agitation

line and one in the line leading to the boom or spray

gun. This permits controlling agitation flow independently

of nozzle flow.

To Adjust For Spraying

To adjust sprayer (regardless of power source - PTO,

belt or pulley), follow these steps:

1. Prime pump with all valves open.

2. Close control valve and agitation line valve; open

boom shut-off valve.

3. With pump running, open the control valve until

pressure gauge indicates desired spraying pressure.

4. Open the agitation line valve until sufficient agitation

is observed. Then, if spraying pressure drops, readjust

the control valve to restore desired pressure.

5. Make sure flow is uniform from all nozzles.

After spraying adjustments are made, it is only

necessary to close boom shut-off valve to discontinue

spraying. On belt-drive models, check belt tension daily

or before each use.

Flush Pump After Use

One of the most common causes for faulty pump

performance is “gumming” or corrosion inside the

pump. Flush the pump and entire system with a solution

that will chemically neutralize the liquid pumped. Mix

according to manufacturer’s directions. This will dissolve

most residue remaining in the pump, leaving the inside

of the pump clean for the next use.

To Prevent Corrosion

After cleaning the pump as directed above, flush it with

a permanent-type automobile antifreeze (Prestone,

Zerex, etc.) containing a rust inhibitor. Use a 50%

solution - that is, half antifreeze and half water. Plug the

ports to keep out air during storage. For short periods of

idleness, non-corrosive liquids may be left in the pump,

BUT AIR MUST BE KEPT OUT. Plug ports or seal port

connections.

Troubleshooting

System Probable Cause(s) Corrective Action(s)

Low Discharge Pump not primed. Remove topmost vent plug from face of pump and run pump to expel trapped air

(See Installation Instructions). Recommend vent line be used (KIT#3430-0456).

Air leaks in suction line. Check and reseal inlet fittings.

Blocked or clogged

line strainer or impeller. Inspect strainer and impeller to clear any debris or obstruction.

Undersize suction line or

collapsed hose. Suction line should be the same diameter as inlet port of pump or larger.

Eye of impeller rubbing Remove volute (front cover) and inspect the impeller. If wear detected, sand

on volute. the impeller eye O.D. with emery cloth.

Liquid leaking Worn seal. Replace seal.

out weep port

Figure 5

Loading...

Loading...