Installation, Operation, Repair and Parts Manual

(12/12, Rev. B)

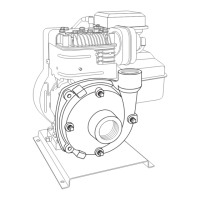

Hypro centrifugal pumps are designed for agricultural and

industrial spraying and transfer of a variety of fluids: water,

insecticides, herbicides, wettable powders, emulsives, liquid

fertilizers, etc. Polypropylene centrifugal pumps may also be

used to pump acid fertilizer, calcium chloride and other highly

corrosive liquids such as sulfuric and phosphoric acids.

Hypro Series 9300 hydraulic motor-driven centrifugal pumps

provide smooth performance. They can be conveniently

mounted on the tractor or sprayer, becoming part of the ve-

hicle’s hydraulic system and freeing the PTO for other uses.

The Hypro “close-coupled” design reduces the mounting

space required, eliminating long shafts and couplers be-

tween the pump and motor.

Form L-1526

Series 9300 Hydraulically-Driven

Centrifugal Pumps

SERIES 9302C & 9302S

Cast Iron & Stainless Steel

Centrifugal Pumps

SERIES 9303P

Polypropylene

Centrifugal Pumps

Max. Flow Rate: .............. 113 gpm

Max. Pressure: ...................125 psi

Ports: ....................1-1/2” NPT Inlet

............................ 1-1/4” NPT Outlet

Hydraulic Ports: ..... 1/2” NPT Inlet

.................................3/4” NPT Tank

Max. Flow Rate: .............. 100 gpm

Max. Pressure: ...................120 psi

Ports: ....................1-1/4” NPT Inlet

.................................. 1” NPT Outlet

Hydraulic Ports: ...... 1/2” NPT Inlet

.................................3/4” NPT Tank

SERIES 9303C-SP

Cast Iron Centrifugal Pumps

Max. Flow Rate: .............. 122 gpm

Max. Pressure: ...................140 psi

Ports: ....................1-1/2” NPT Inlet

............................ 1-1/4” NPT Outlet

Hydraulic Ports: ...... 1/2” NPT Inlet

.................................3/4” NPT Tank

SERIES 9305C-HM3C

Cast Iron Centrifugal Pumps

Max. Flow Rate: .............. 190 gpm

Max. Pressure: ...................180 psi

Ports: .......................... 2” NPT Inlet

............................ 1-1/2” NPT Outlet

Hydraulic Ports: ...... 1/2” NPT Inlet

.................................3/4” NPT Tank

SERIES 9305C-

HM3C-SP, -BSP

Cast Iron Centrifugal Pumps

Max. Flow Rate: .............. 178 gpm

Max. Pressure: ...................154 psi

Ports: ..............2” NPT or BSP Inlet

......................2” NPT or BSP Outlet

Hydraulic Ports: ...... 1/2” NPT Inlet

.................................3/4” NPT Tank

SERIES 9303C & 9303S

Cast Iron & Stainless Steel

Centrifugal Pumps

Max. Flow Rate: .............. 147 gpm

Max. Pressure: ...................145 psi

Ports: ....................1-1/2” NPT Inlet

............................ 1-1/4” NPT Outlet

Hydraulic Ports: ...... 1/2” NPT Inlet

.................................3/4” NPT Tank

SERIES 9306C & 9306S

Cast Iron & Stainless Steel

Centrifugal Pumps

Max. Flow Rate: .............. 214 gpm

Max. Pressure: ...................150 psi

Ports: .......................... 2” NPT Inlet

............................ 1-1/2” NPT Outlet

Hydraulic Ports: ..... 1/2” NPT Inlet

.................................3/4” NPT Tank

Description

Loading...

Loading...