36 37

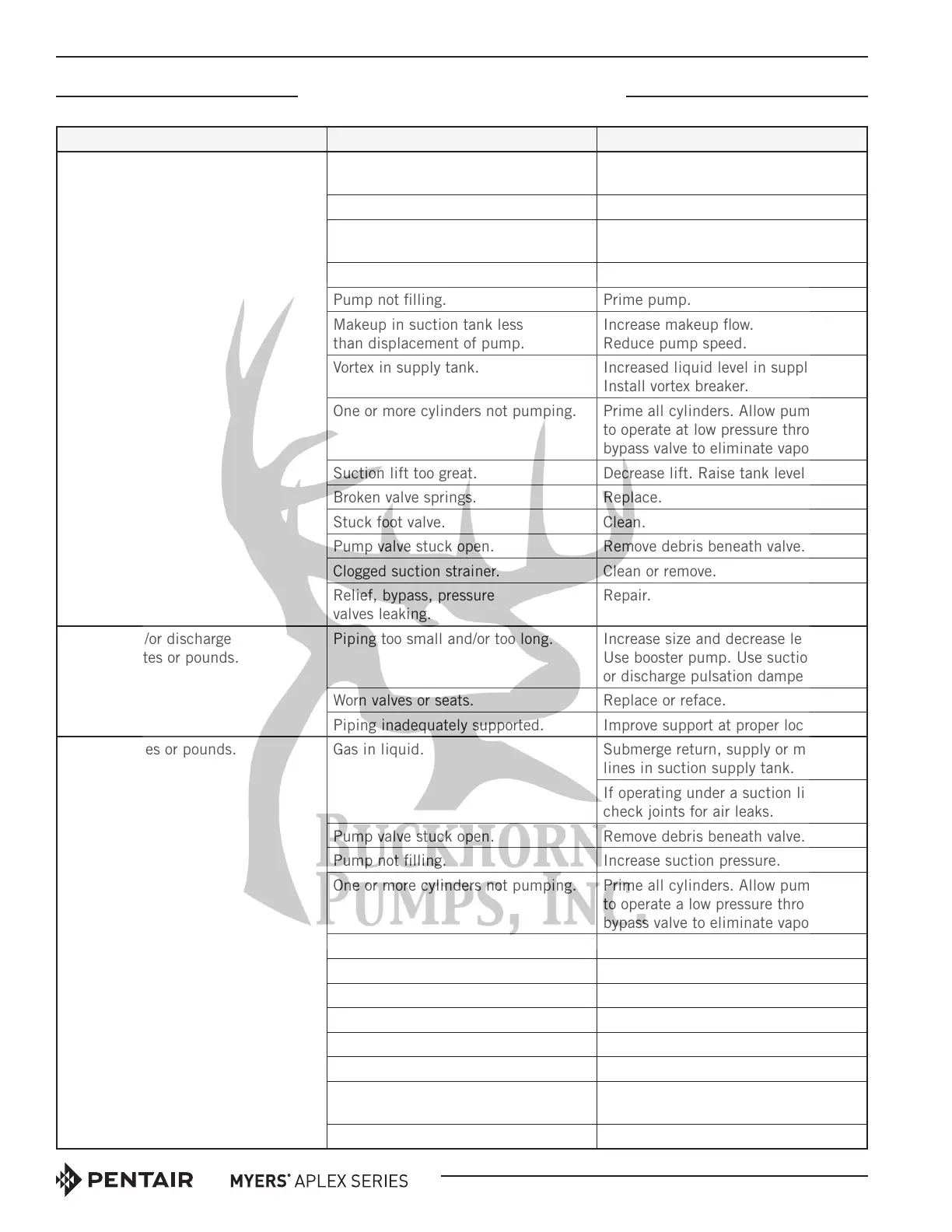

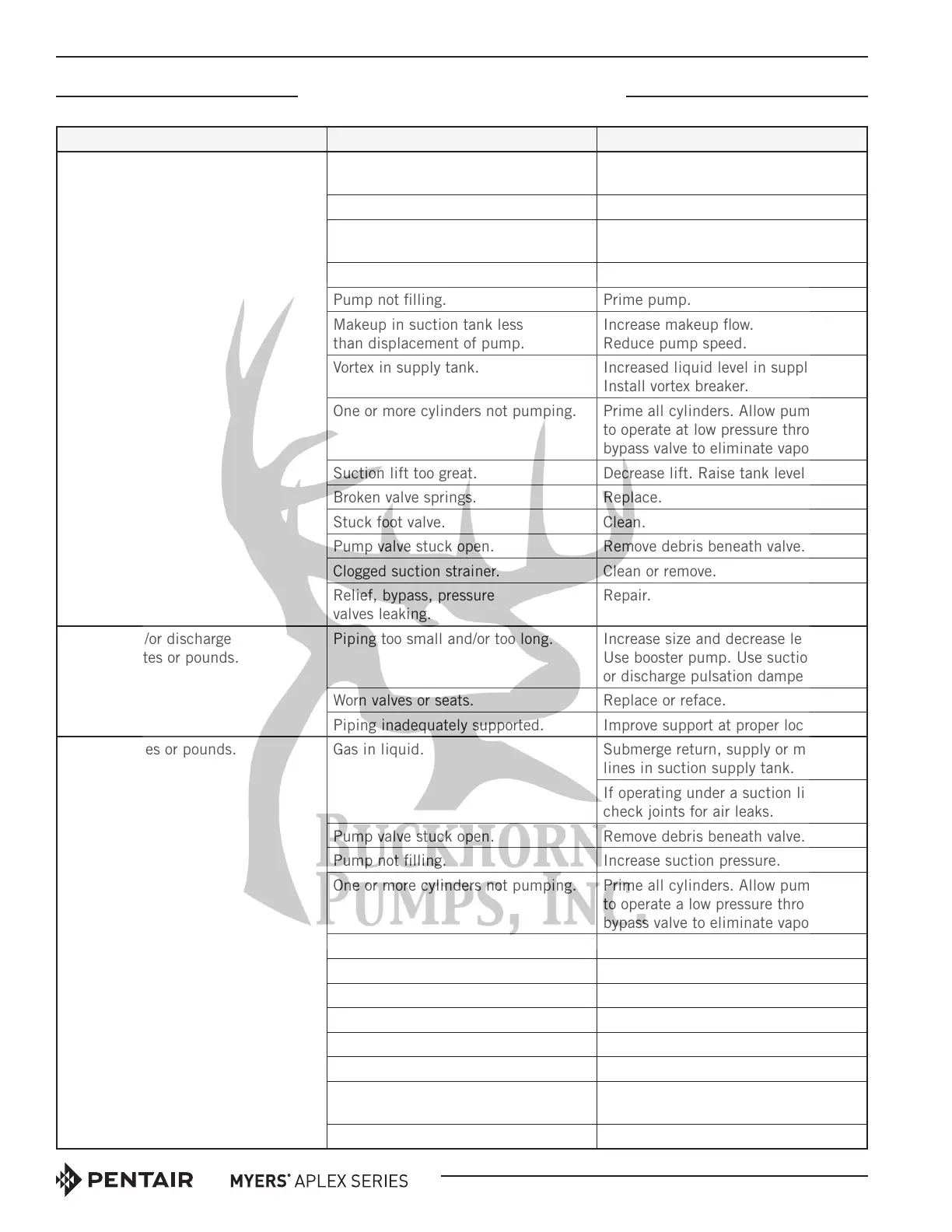

Trouble Possible Cause Remedy

Pump fails to deliver

required capacity.

Speed incorrect.

Belts slipping.

Change drive ratio or tighten

belts (if loose). Correct motor speed.

Air leaking into pump. Seal with compounds.

Liquid cylinder valves,

seats or plungers worn.

Reface or lap valves and seats;

replace packing or plungers.

Insufficient NPSHA. Increase suction pressure.

Pump not filling. Prime pump.

Makeup in suction tank less

than displacement of pump.

Increase makeup flow.

Reduce pump speed.

Vortex in supply tank. Increased liquid level in supply tank.

Install vortex breaker.

One or more cylinders not pumping. Prime all cylinders. Allow pump

to operate at low pressure through

bypass valve to eliminate vapor.

Suction lift too great. Decrease lift. Raise tank level.

Broken valve springs. Replace.

Stuck foot valve. Clean.

Pump valve stuck open. Remove debris beneath valve.

Clogged suction strainer. Clean or remove.

Relief, bypass, pressure

valves leaking.

Repair.

Suction and/or discharge

piping vibrates or pounds.

Piping too small and/or too long. Increase size and decrease length.

Use booster pump. Use suction and/

or discharge pulsation dampeners.

Worn valves or seats. Replace or reface.

Piping inadequately supported. Improve support at proper locations.

Pump vibrates or pounds. Gas in liquid. Submerge return, supply or makeup

lines in suction supply tank.

If operating under a suction lift,

check joints for air leaks.

Pump valve stuck open. Remove debris beneath valve.

Pump not filling. Increase suction pressure.

One or more cylinders not pumping. Prime all cylinders. Allow pump

to operate a low pressure through

bypass valve to eliminate vapor.

Excessive pump speed. Reduce. Check drive ratio.

Worn valves or seats. Replace or reface.

Broken valve spring. Replace.

Loose plunger. Tighten.

Loose or worn bearings. Adjust or replace.

Worn crossheads or guides. Replace.

Loose crosshead pin.

Loose connecting rod cap bolts.

Adjust or replace.

Pump running backward. Correct rotation.

TROUBLE LOCATION AND REMEDY

Loading...

Loading...