32 33

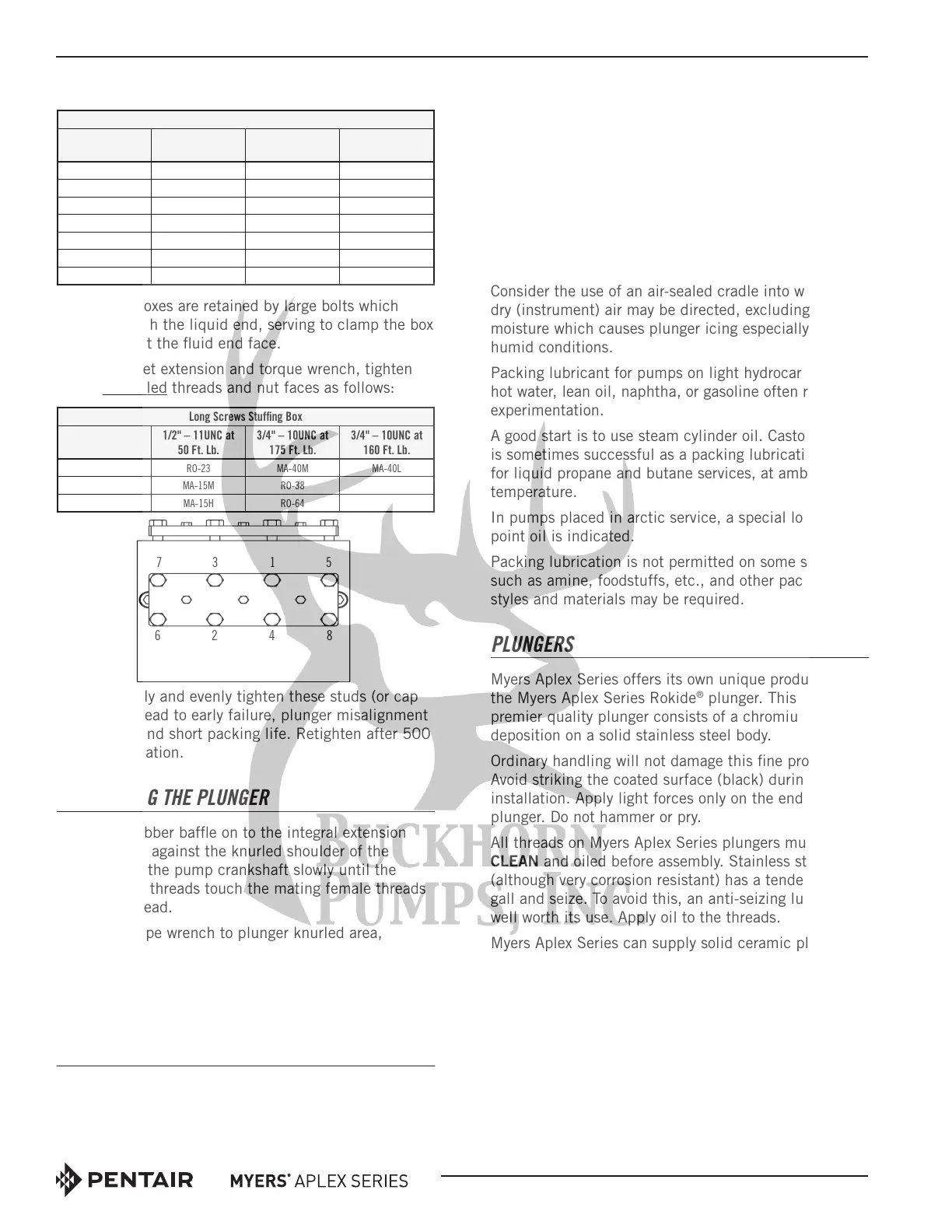

The torque value for each pump should be as follows:

Stud Threads

5/8" – 11UNC at

100 Ft. Lb

3/4" – 11UNC at

100 Ft. Lb.

7/8" – 9UNC at

250 Ft. Lb.

3/4" – 11UNC at

160 Ft. Lb.

SC-30 SC-45 SC-65 MA-25M

SC-30H SC-45H SC-65H MA-25L

RO-23 SC-45L SC-65L

MA-15M RO-38

MA-15H RO-64

MA-40M

MA-40L

All stuffing boxes are retained by large bolts which

extend through the liquid end, serving to clamp the box

tightly against the fluid end face.

Using a socket extension and torque wrench, tighten

clean, well-oiled threads and nut faces as follows:

Long Screws Stuffing Box

5/8" – 11UNC at

100 Ft. Lb.

1/2" – 11UNC at

50 Ft. Lb.

3/4" – 10UNC at

175 Ft. Lb.

3/4" – 10UNC at

160 Ft. Lb.

MA-25L RO-23 MA-40M MA-40L

MA-25M MA-15M RO-38

MA-15H RO-64

Failure to fully and evenly tighten these studs (or cap

screws) can lead to early failure, plunger misalignment

and failure, and short packing life. Retighten after 500

hours of operation.

CONNECTING THE PLUNGER

Install the rubber baffle on to the integral extension

rod, sliding it against the knurled shoulder of the

plunger. Roll the pump crankshaft slowly until the

plunger male threads touch the mating female threads

in the crosshead.

Applying a pipe wrench to plunger knurled area,

thoroughly tighten the connection. Do NOT use a

“cheater” when connecting plunger to extension rod.

(Serves no useful purpose, and may damage the

connection!)

PACKING

Packing life for aramid fiber packing may be improved

in some applications by regular, systematic lubrication.

An optional force feed lubricator assembly is often

recommended especially for pumps on continuous

duty. This provides regular, controlled supply of

lubricant lowering friction and heat.

Additionally, the regular application of the correct

lubricant aids dissolving of salt and gyp tending

to build up on the plungers in produced water

applications. For this service, Rock Drill Lubricant is a

popular and effective packing lubricant.

Plungers in CO

2

, ethane, or other very cold liquid

services may use brake fluid. This fluid does not

congeal into a solid which cannot enter the packing.

Consider the use of an air-sealed cradle into which

dry (instrument) air may be directed, excluding the

moisture which causes plunger icing especially in very

humid conditions.

Packing lubricant for pumps on light hydrocarbons,

hot water, lean oil, naphtha, or gasoline often requires

experimentation.

A good start is to use steam cylinder oil. Castor oil

is sometimes successful as a packing lubrication

for liquid propane and butane services, at ambient

temperature.

In pumps placed in arctic service, a special low pour

point oil is indicated.

Packing lubrication is not permitted on some services,

such as amine, foodstuffs, etc., and other packing

styles and materials may be required.

PLUNGERS

Myers Aplex Series offers its own unique product:

the Myers Aplex Series Rokide

®

plunger. This

premier quality plunger consists of a chromium-oxide

deposition on a solid stainless steel body.

Ordinary handling will not damage this fine product.

Avoid striking the coated surface (black) during

installation. Apply light forces only on the ends of the

plunger. Do not hammer or pry.

All threads on Myers Aplex Series plungers must be

CLEAN and oiled before assembly. Stainless steel

(although very corrosion resistant) has a tendency to

gall and seize. To avoid this, an anti-seizing lubricant is

well worth its use. Apply oil to the threads.

Myers Aplex Series can supply solid ceramic plungers

on order. This plunger is very fragile, vulnerable to

thermal and mechanical shock, and must be handled

with the greatest care. Use only a rubber mallet to

insert it into the packing. Other plunger types are

available upon request.

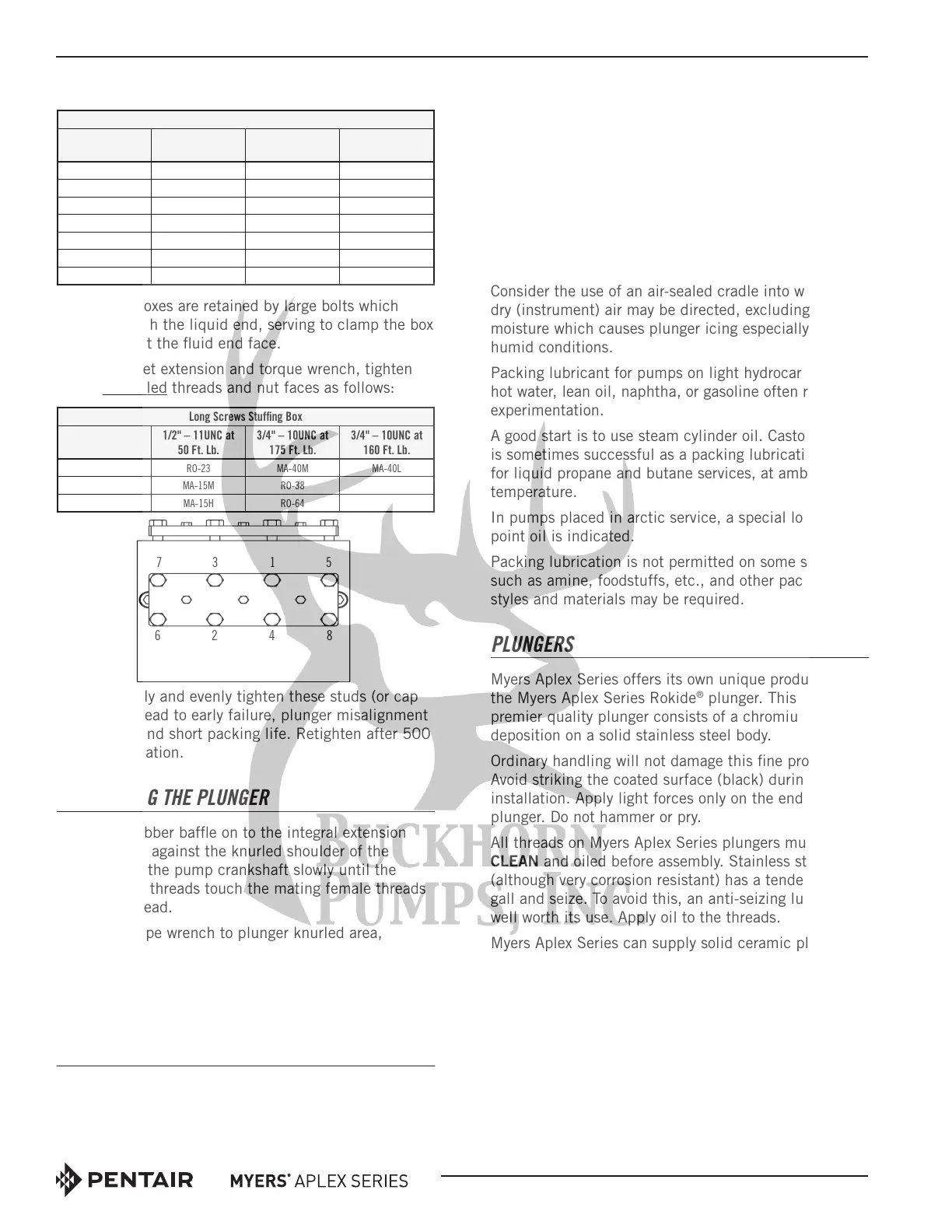

3 1 5

2 4 8

Loading...

Loading...