31

cord is looped over the ends of the spring through the

coils and tied to maintain the length mentioned above.

Each spring is assembled into the stuffing box. Note

that the spring does not contact the plunger.

Spring-Guide Ring:

Plungers are heavy and the importance of a well-fitted

guide ring that carries this weight is often overlooked.

Discard any guide ring that becomes worn or scored, as

it will then not serve its purpose. It should fit snugly in

the box. Apply oil generously to this ring.

Spring Loaded Packing:

Three (3) rings of chevron or compression packing

are installed next. For compression packing, install

them with the skive intersections 180º apart to

discourage leaking.

Gland Ring:

This ring also fits the plunger and helps support the

plunger weight. Discard it if bore is worn, rough or out-

of-round. Lightly oil the ring before insertion.

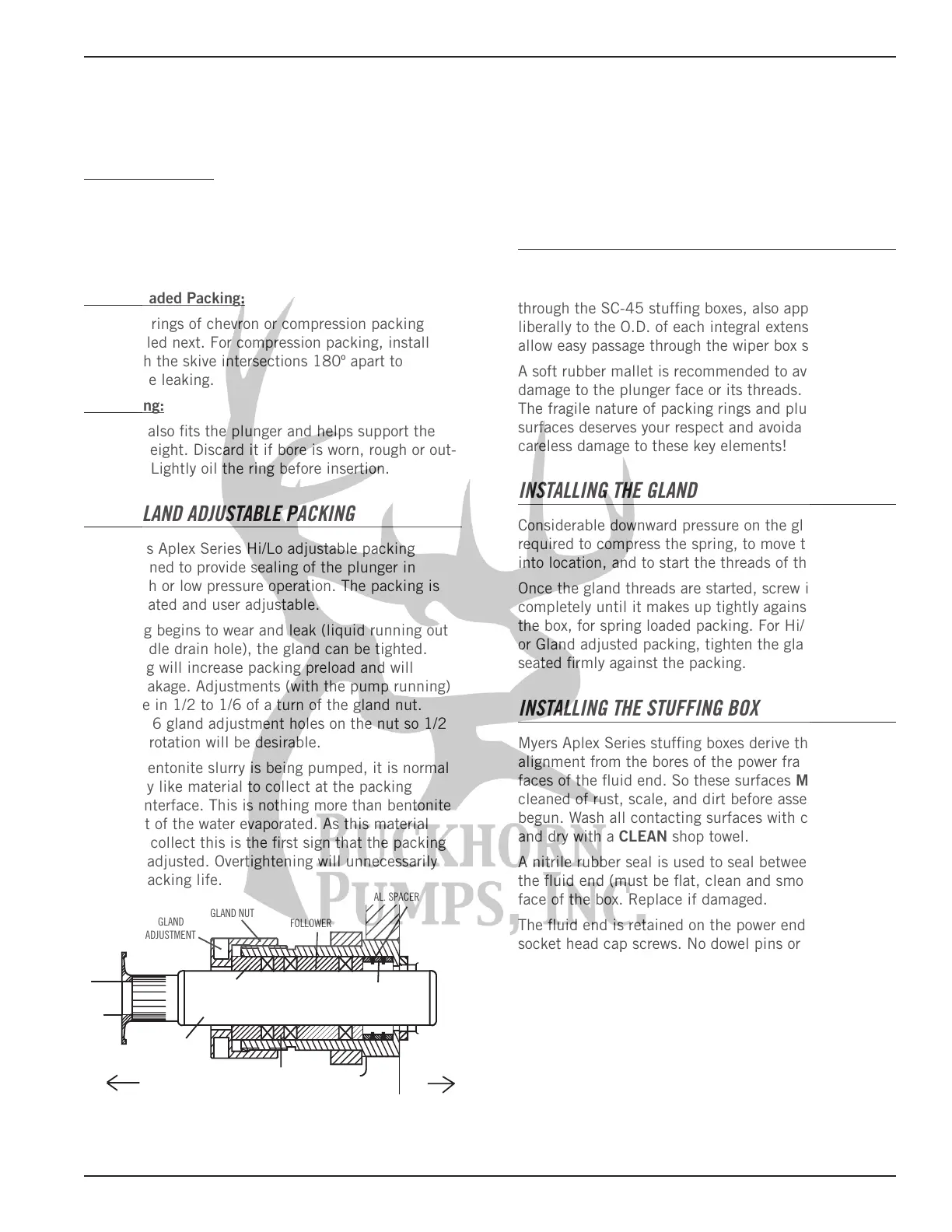

HI/LO GLAND ADJUSTABLE PACKING

The Myers Aplex Series Hi/Lo adjustable packing

was designed to provide sealing of the plunger in

either high or low pressure operation. The packing is

nonlubricated and user adjustable.

If packing begins to wear and leak (liquid running out

of the cradle drain hole), the gland can be tighted.

Tightening will increase packing preload and will

control leakage. Adjustments (with the pump running)

should be in 1/2 to 1/6 of a turn of the gland nut.

There are 6 gland adjustment holes on the nut so 1/2

to 1 hole rotation will be desirable.

When a bentonite slurry is being pumped, it is normal

for a putty like material to collect at the packing

plunger interface. This is nothing more than bentonite

with most of the water evaporated. As this material

begins to collect this is the first sign that the packing

could be adjusted. Overtightening will unnecessarily

shorten packing life.

The Hi/Lo packing is totally retrofitable to existing

Myers Aplex Series pump. Use the drawing for proper

reassembly order.

Initial gland tightening should be 2 to 2-1/4 turns past

hand tight. If there is a grease fitting in the stuffing

box, remove it. Use a 1/8" pipe plug and plug the hole.

CAUTION: Make sure the plug does not protrude down

into the I.D. of the stuffing box. If the plug is too long,

grind off the end and try again.

INSERTING THE PLUNGER

Apply oil liberally to plunger O.D. and lightly tap it

through the packing. When introducing the plunger

through the SC-45 stuffing boxes, also apply oil

liberally to the O.D. of each integral extension rod to

allow easy passage through the wiper box seals.

A soft rubber mallet is recommended to avoid any

damage to the plunger face or its threads. Remember:

The fragile nature of packing rings and plunger

surfaces deserves your respect and avoidance of

careless damage to these key elements!

INSTALLING THE GLAND

Considerable downward pressure on the gland is

required to compress the spring, to move the packing

into location, and to start the threads of the box.

Once the gland threads are started, screw it down

completely until it makes up tightly against the face of

the box, for spring loaded packing. For Hi/Lo, J-Style

or Gland adjusted packing, tighten the gland until it is

seated firmly against the packing.

INSTALLING THE STUFFING BOX

Myers Aplex Series stuffing boxes derive their

alignment from the bores of the power frame and the

faces of the fluid end. So these surfaces MUST be

cleaned of rust, scale, and dirt before assembly is

begun. Wash all contacting surfaces with clean solvent

and dry with a CLEAN shop towel.

A nitrile rubber seal is used to seal between the face of

the fluid end (must be flat, clean and smooth) and the

face of the box. Replace if damaged.

The fluid end is retained on the power end by two

socket head cap screws. No dowel pins or other

alignment techniques are needed since the power

frame provides alignment to the stuffing boxes

individually. These two screws should be tightened

before the stuffing boxes.

SUPPORT RING

FOLLOWER

GLAND

ADJUSTMENT

HOLE

GLAND NUT

GLAND RING

ELASTOMER SPRING

POWER END

FLUID END

PLUNGER

Loading...

Loading...