28 29

Crosshead O.D.:

2.622/2.619

New Frame Bores:

2.625/2.628

Crosshead O.D.:

3.243/3.246

New Frame Bores:

3.253/3.250

Crosshead O.D.:

3.996/3.993

New Frame Bores:

4.000/4.004

MA-15M MA-25M MA-40L

MA-15H MA-25L MA-40M

SC-30 SC-45 SC-65

SC-30H SC-45L SC-65H

RO-23 SC-45H SC-65L

RO-38 RO-64

Frame bores which have become worn more than

0.015" must be sleeved with a cast iron liner to

reestablish correct geometry and alignment. Contact

Aurora pump, Aplex series concerning badly worn

frame bores.

Smooth any rough corners and edges on the crosshead

skirts, using fine emery cloth. Examine and clean the

female tapered threads and wrist pin holes.

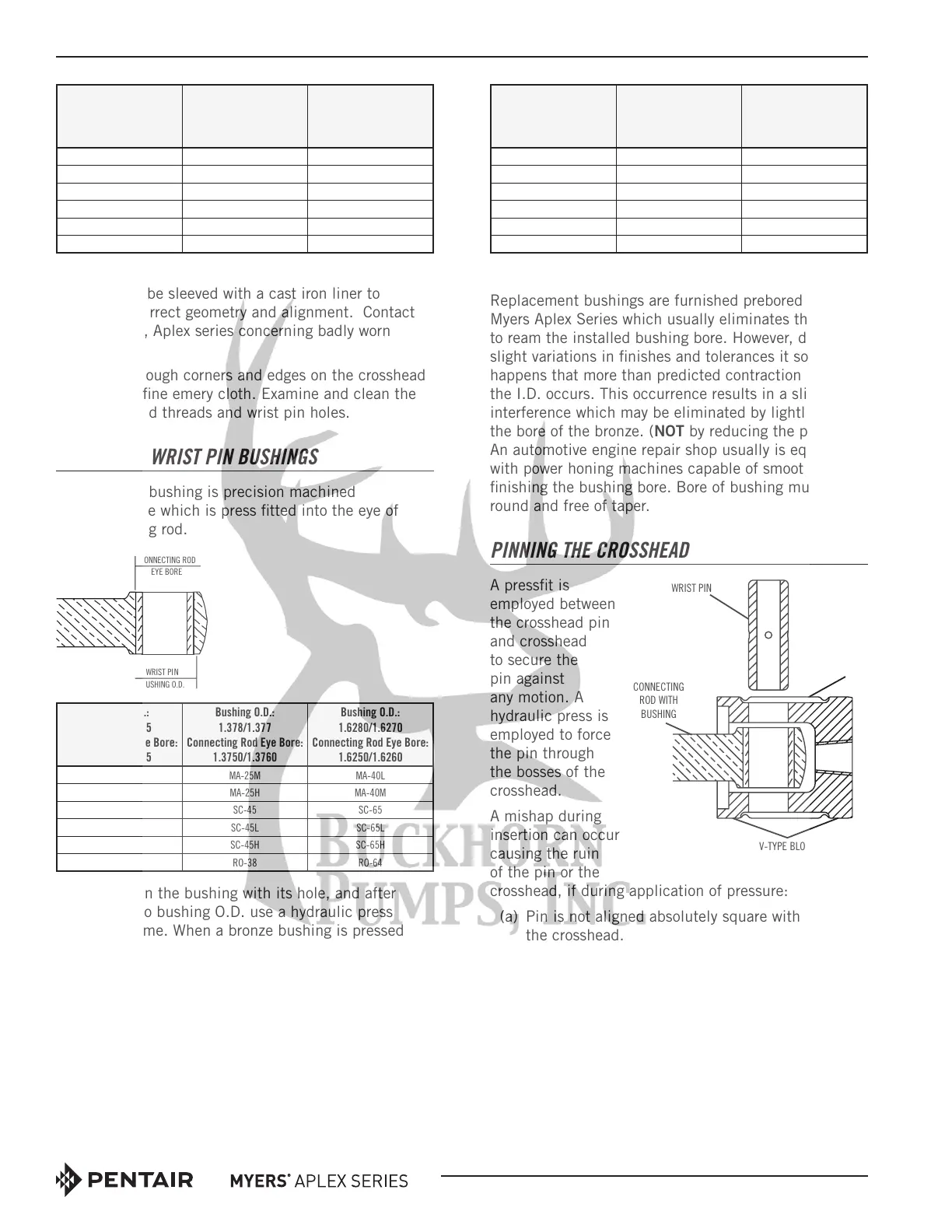

INSTALLING WRIST PIN BUSHINGS

The wrist pin bushing is precision machined

bearing bronze which is press fitted into the eye of

the connecting rod.

Bushing O.D.:

1.0625/1.0645

Connecting Rod Eye Bore:

1.0625/1.0635

Bushing O.D.:

1.378/1.377

Connecting Rod Eye Bore:

1.3750/1.3760

Bushing O.D.:

1.6280/1.6270

Connecting Rod Eye Bore:

1.6250/1.6260

MA-15M MA-25M MA-40L

MA-15H MA-25H MA-40M

SC-30 SC-45 SC-65

SC-30H SC-45L SC-65L

RO-23 SC-45H SC-65H

RO-38 RO-64

Carefully align the bushing with its hole, and after

applying oil to bushing O.D. use a hydraulic press

to force it home. When a bronze bushing is pressed

into place, the I.D. (bore) of the bushing is reduced

somewhat, owing to the extent of press fit. Therefore,

a clean, new wrist pin should be inserted into the

bushing bore to establish that running clearance has

been obtained. The running clearance between the

wrist pin and installed bushing is:

New Pin O.D.:

0.8140/0.8135

Installed Bushing Bore:

0.8145/0.8150

New Pin O.D.:

1.0640/1.0635

Installed Bushing Bore:

1.0645/1.0650

New Pin O.D.:

1.3140/1.3135

Installed Bushing Bore:

1.3145/1.3155

MA-15M MA-25L MA-40L

MA-15H MA-25M MA-40M

SC-30 SC-45 SC-65

SC-30H SC-45L SC-65L

RO-23 SC-45H SC-65H

RO-38 RO-64

Oil Clearance ........................................0005/.0015"

Replacement bushings are furnished prebored by

Myers Aplex Series which usually eliminates the need

to ream the installed bushing bore. However, due to

slight variations in finishes and tolerances it sometimes

happens that more than predicted contraction of

the I.D. occurs. This occurrence results in a slight

interference which may be eliminated by lightly honing

the bore of the bronze. (NOT by reducing the pin size!)

An automotive engine repair shop usually is equipped

with power honing machines capable of smoothly

finishing the bushing bore. Bore of bushing must be

round and free of taper.

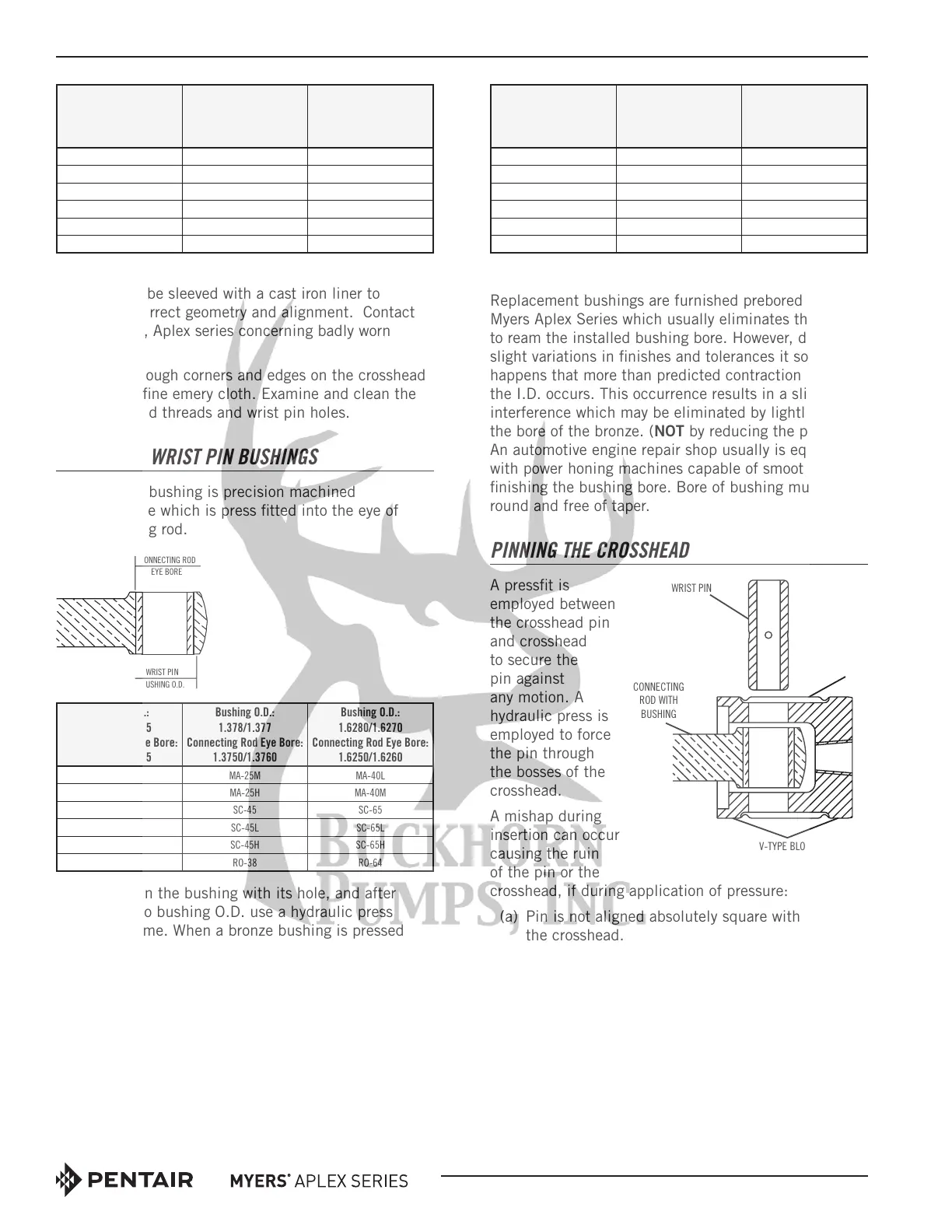

PINNING THE CROSSHEAD

A pressfit is

employed between

the crosshead pin

and crosshead

to secure the

pin against

any motion. A

hydraulic press is

employed to force

the pin through

the bosses of the

crosshead.

A mishap during

in sertion can occur

caus ing the ruin

of the pin or the

crosshead, if during application of pres sure:

(a) Pin is not aligned absolutely square with

the crosshead.

(b) Crosshead is not sup ported on v-blocks so it can

roll while under load.

(c) Con necting rod is not ful ly support ed so pin

cannot en ter the bushing without damage to it.

This will damage the bush ing.

(d) Fail ure to oil pin O.D. and crosshead bores, to

prevent galling. Use clean motor oil.

After in stalling the pin, carefully check the crosshead

O.D. to see if it is out-of-round. If so, a smart blow with

WRIST PIN

CONNECTING

ROD WITH

BUSHING

CONNECTING ROD

EYE BORE

WRIST PIN

Loading...

Loading...