26 27

After about one week of operation, new V-belts will

have stretched somewhat. The motor must be moved

on its slide base to re-establish proper belt tensioning.

Insufficient tension results in slippage, burning,

squealing (especially during starting) and shortened

belt life. Overtightening imposes excessive loads on

pump and motor bearings and can cause early shaft

fatigue failure.

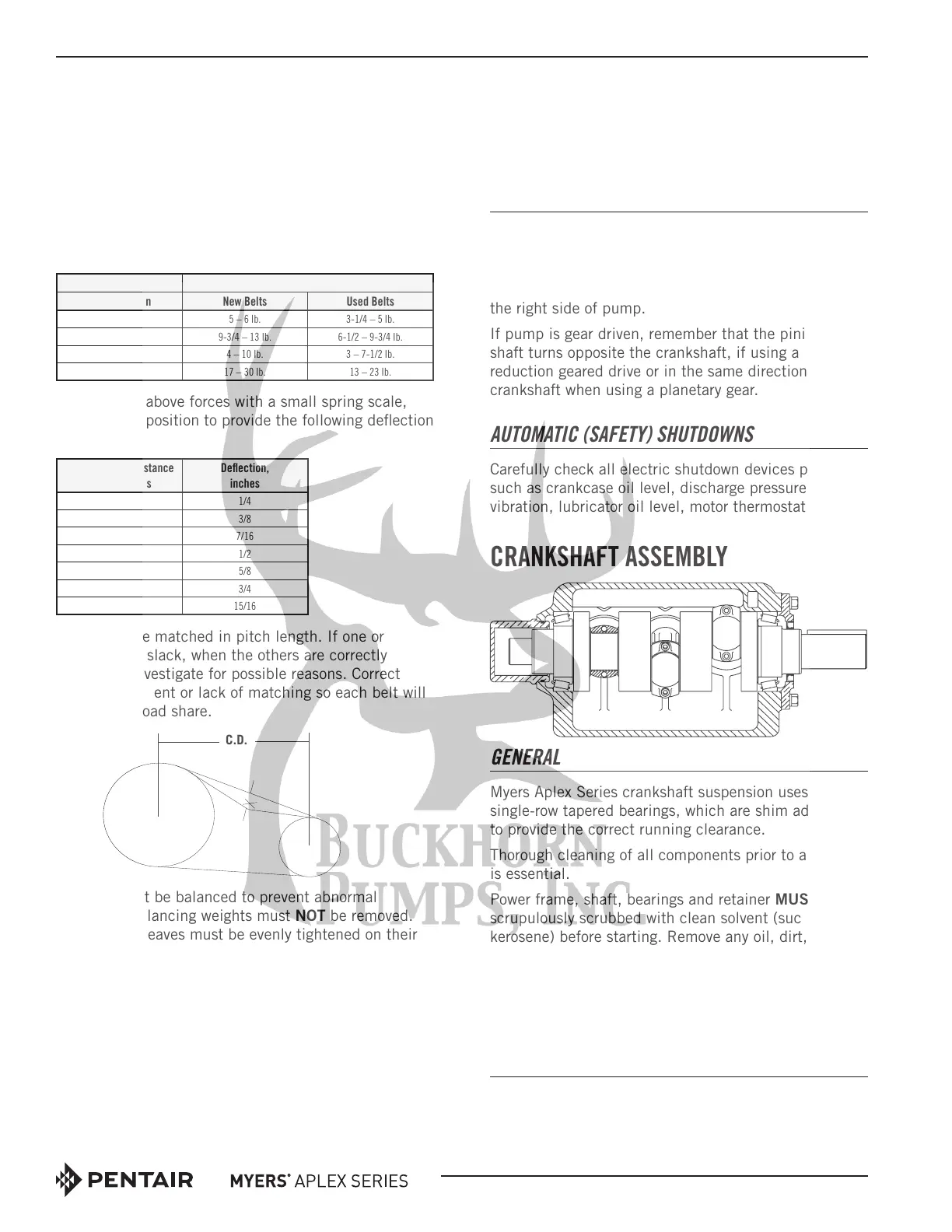

Use the following table in adjusting V-belt tension:

Belt Tension at Mid-Span

Cross-Section New Belts Used Belts

“B” 5 – 6 lb. 3-1/4 – 5 lb.

“C” 9-3/4 – 13 lb. 6-1/2 – 9-3/4 lb.

“3V” 4 – 10 lb. 3 – 7-1/2 lb.

“5V” 17 – 30 lb. 13 – 23 lb.

Applying the above forces with a small spring scale,

adjust motor position to provide the following deflection

at mid-span:

Approx. Center Distance

(Span), inches

Deflection,

inches

16 1/4

22 3/8

28 7/16

32 1/2

40 5/8

48 3/4

60 15/16

Belts must be matched in pitch length. If one or

two belts are slack, when the others are correctly

tensioned, investigate for possible reasons. Correct

any misalignment or lack of matching so each belt will

transmit its load share.

Sheaves must be balanced to prevent abnormal

vibration. Balancing weights must NOT be removed.

Type “QD” sheaves must be evenly tightened on their

tapered hubs to avoid rim wobble and severe lateral

vibration. V-belts that snap and jerk will produce

abnormal vibration and loads on both pump and motor

or engine.

Run the pump several minutes at full load with belt

guard re moved, observing for uneven motion on the

belt slack side, espe cially.

When an old V-belt drive becomes unserviceable,

replace ALL belts, not just the broken or cracked belts.

Do not operate belts on sheaves having worn, rusted,

greasy or broken grooves. Shut off power to driver

before servicing drive or pump.

WARNING: Do not operate without appropriate guards

in place.

DIRECTION OF ROTATION

Before placing pump in operation, check that

crankshaft rotation agrees with the arrows cast on top

of the power frame by briefly jogging the electric motor.

Crankshaft rotation must be clockwise as viewed from

the right side of pump.

If pump is gear driven, remember that the pinion

shaft turns opposite the crankshaft, if using a single-

reduction geared drive or in the same direction as the

crankshaft when using a planetary gear.

AUTOMATIC (SAFETY) SHUTDOWNS

Carefully check all electric shutdown devices present,

such as crankcase oil level, discharge pressure,

vibration, lubricator oil level, motor thermostat, etc.

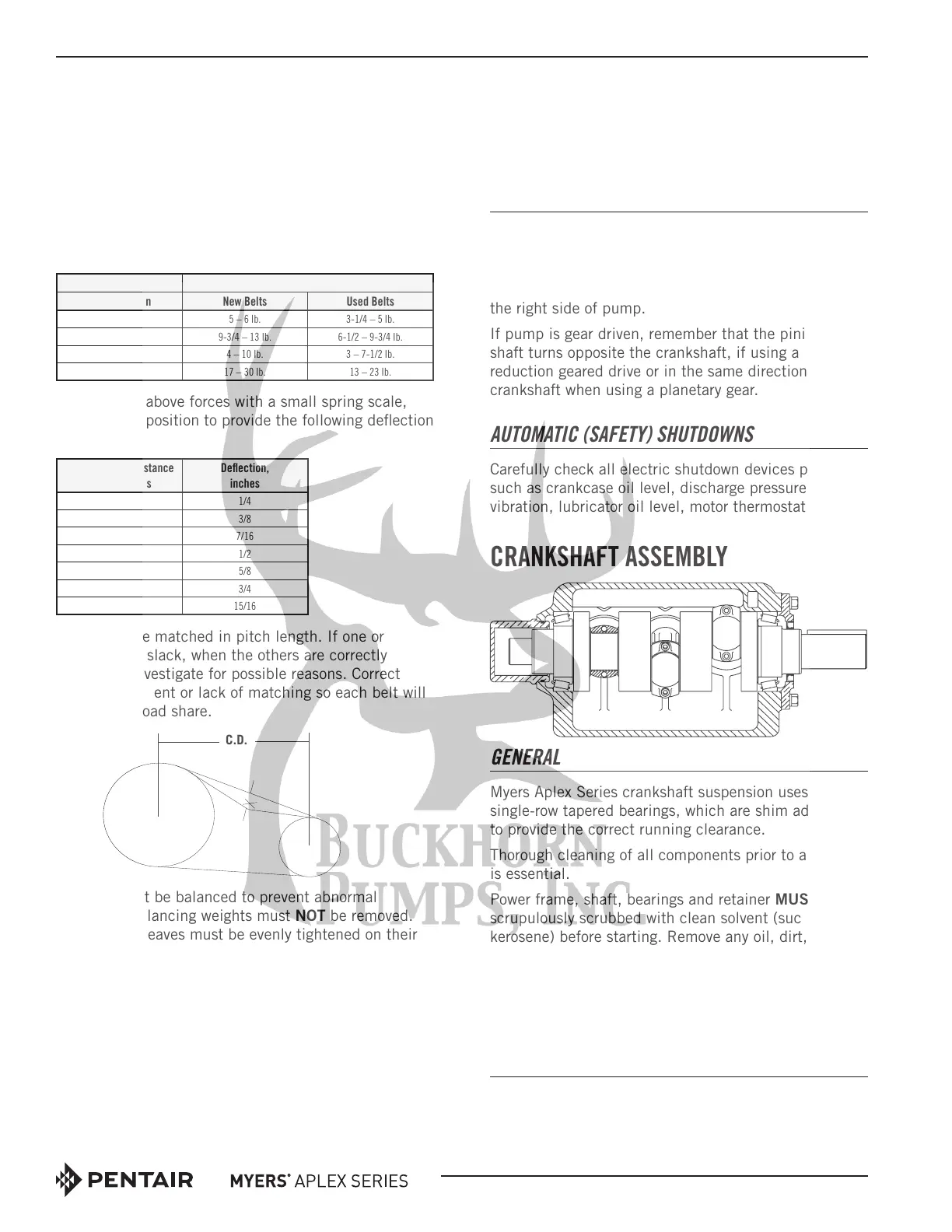

CRANKSHAFT ASSEMBLY

GENERAL

Myers Aplex Series crankshaft suspension uses two

single-row tapered bearings, which are shim adjusted

to provide the correct running clearance.

Thorough cleaning of all components prior to assembly

is essential.

Power frame, shaft, bearings and retainer MUST be

scrupulously scrubbed with clean solvent (such as

kerosene) before starting. Remove any oil, dirt, rust and

foreign matter which might prevent the correct fit up.

Crankshaft journals are critical. Remove all burrs, rust

spots, and nicks, paying special attention to the ground

areas on which bearings and oil seals operate.

TAPERED ROLLER BEARINGS

Shaft and frame tolerances provide a tight (shrink) fit

on the shaft and in the carrier. The best way to install

the cone assembly (consists of the inner race, cage

C.D.

Loading...

Loading...