33

CONVERTING PLUNGER TO PISTON

DISASSEMBLY:

1. Remove the 8 cap screws and the cylinder head

retaining plate from the front of the liquid end.

2. Unscrew the 3 glands from the stuffing boxes

and remove. Unscrew the 3 plungers from the

crossheads and work them gently through the

wiper box seals and plunger packing. Pull them

out the front of the pump.

3. Pull the stuffing box retainer plate to the back of

the cradle, and remove the 3 stuffing boxes.

REASSEMBLY:

1. Install the 3 liners in place of the stuffing boxes.

2. Pull the stuffing box retainer plate over the

3 liners.

3. Snap the piston cup over the piston hub.

Assemble the piston rod, O-ring, piston assembly,

piston keeper and nylock socket head cap screw

(12mm hex) together.

4. Insert the entire piston assembly through the

liquid end, liner and wiper box and screw into the

crosshead. Once it is assembled you can tighten

the nylock screw into the piston rod.

5. Reinstall the cylinder head retainer plate and 8

cap screws. Torque in an even manner as shown

in the service manual.

CHANGING PISTON CUPS

1. Remove the 8 cap screws and the cylinder head

retaining plate from the front of the liquid end.

2. Unscrew the nylock socket head cap screw

(12mm hex) and remove with piston keeper.

3. Screw a 5/8"-11UNC all thread stud into the

piston hub and remove from liner. Make sure the

O-ring comes out also.

4. Change piston cup and reinstall with a new O-ring

and nylock screw. Inspect the piston hub for wear.

It should be changed periodically.

5. Reinstall the cylinder head retainer plate and 8

cap screws. Torque in an even manner as shown

on previous page.

DISC VALVE SYSTEMS AND

ABRASION RESISTANT

GENERAL

Myers Aplex Series has developed a unique setting/

puller system permitting quick, easy and safe methods

of installing and removing tapered seat valves.

The system allows servicing without distortion of the

seat, with minimum effort and NO damage to fluid end

tapers or seat.

Tapered seats notoriously drive solidly down into

mating deck tapers, so firmly that extraction heretofore

has always posed severe problems. Old style valves

may be pulled only with the greatest effort, using “J”

puller heads (prone to failure), CO

2

– dry ice, and

other improvisations.

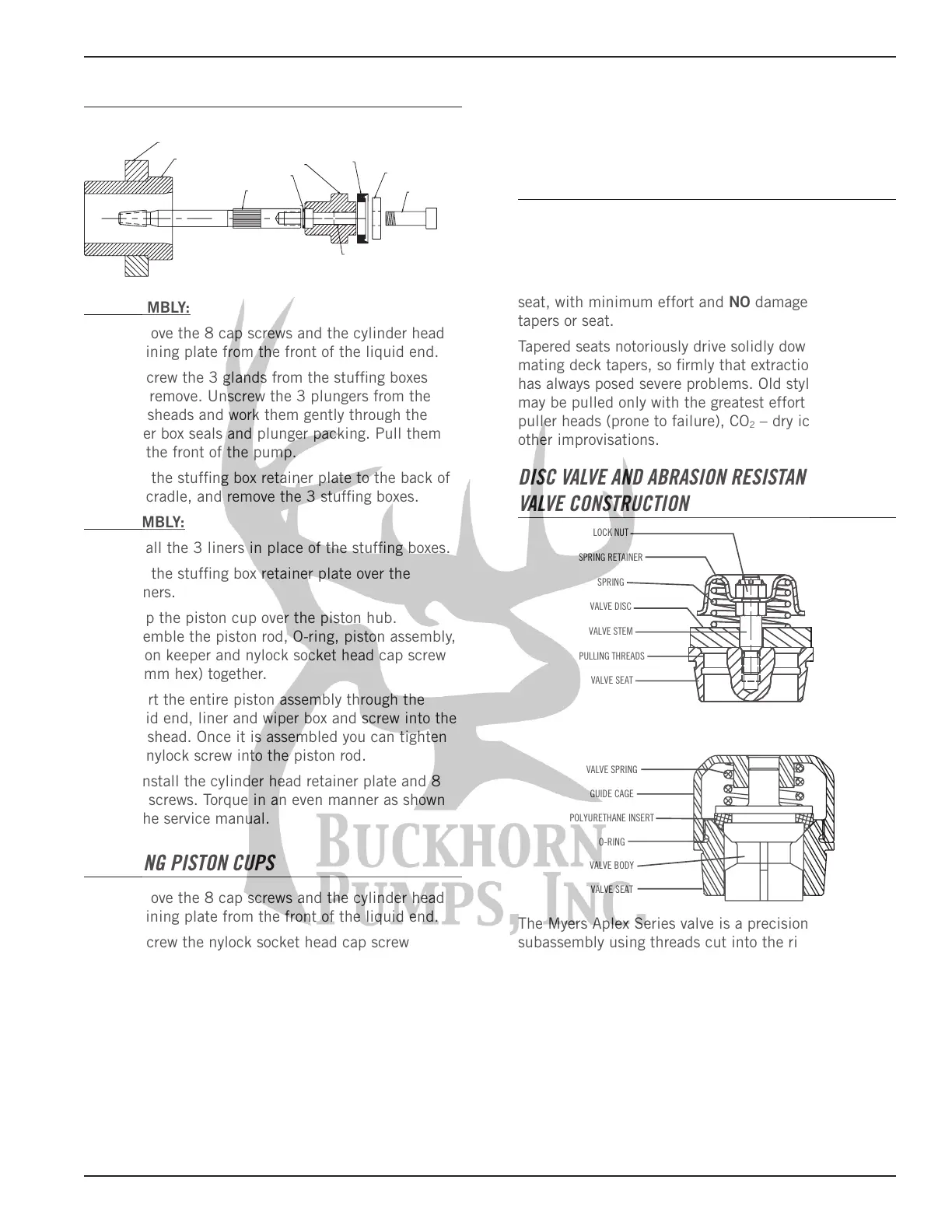

DISC VALVE AND ABRASION RESISTANT

VALVE CONSTRUCTION

The Myers Aplex Series valve is a precision made

subassembly using threads cut into the rim of seat

for use with Myers Aplex Series setting/pulling tool.

These threads do NOT deteriorate as proved by field

experience. By locating these on the rim, setting/

pulling forces are now applied only to the rim of the

seat, never to the webs (or “spokes”), or to the center

section. Distortion of the seat is eliminated.

Access to these seat threads is provided by the removal

of the valve cage on abrasion resistant valve or the

spring retainer on disc valves which is screwed onto the

seat. An anti-seizing lubricant applied to all threads is

good insurance against future difficulty.

THESE THREADS FOR

PULLING ONLY

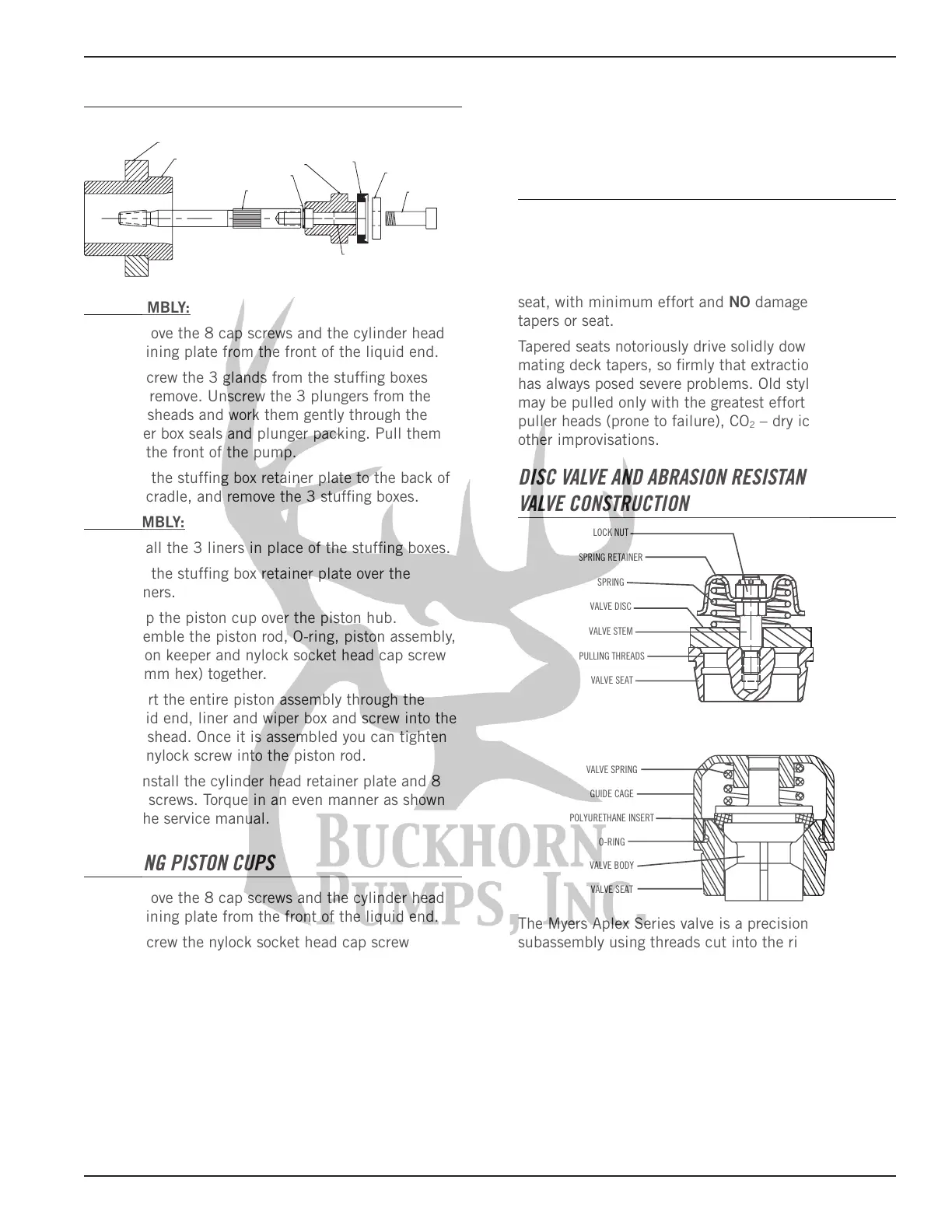

NYLOCK SCREW

PISTON KEEPER

PISTON CUP

PISTON HUB

O-RING

PISTON ROD

LINER

RETAINER PLATE

LOCK NUT

SPRING RETAINER

SPRING

VALVE DISC

VALVE STEM

PULLING THREADS

VALVE SEAT

VALVE SPRING

GUIDE CAGE

POLYURETHANE INSERT

VALVE BODY

O-RING

VALVE SEAT

Loading...

Loading...