6

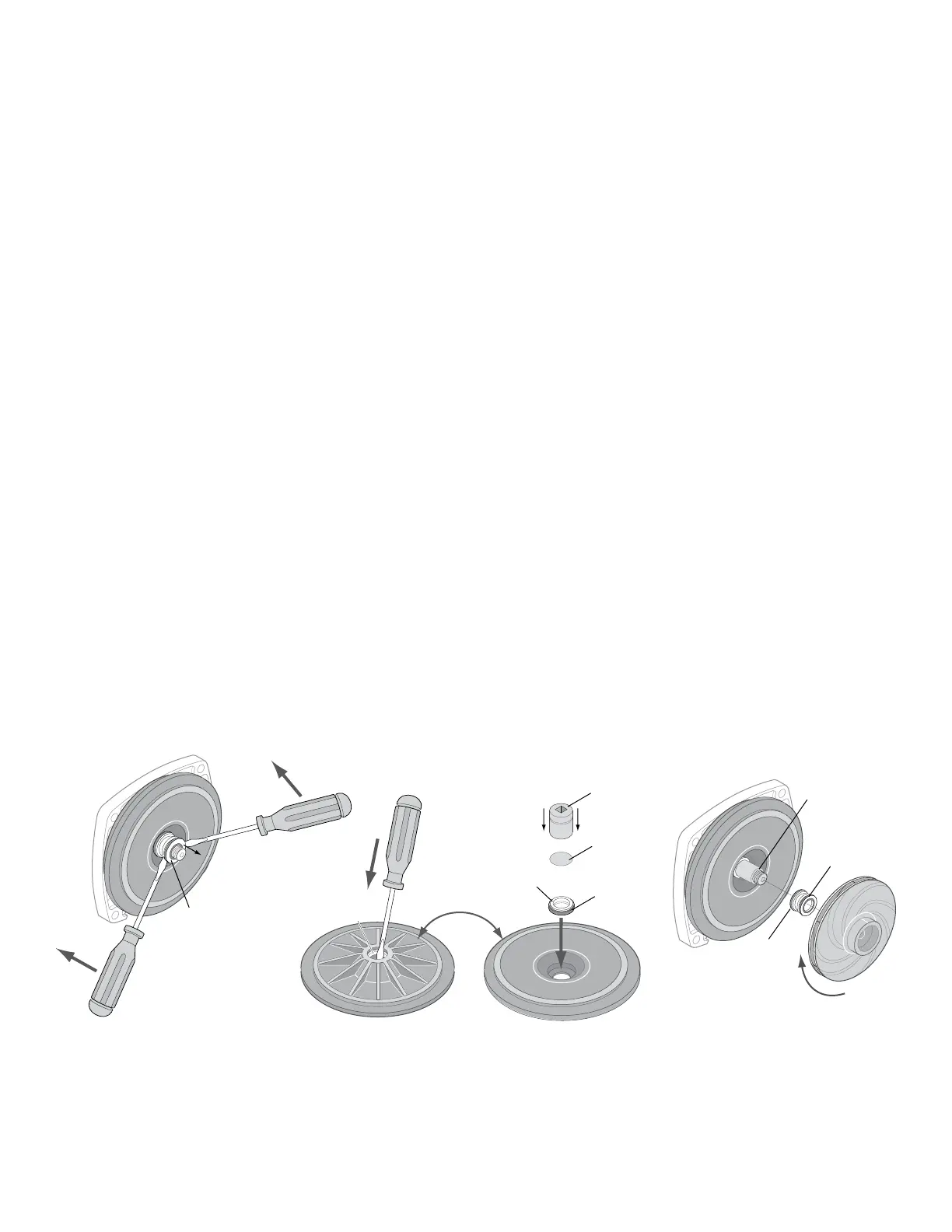

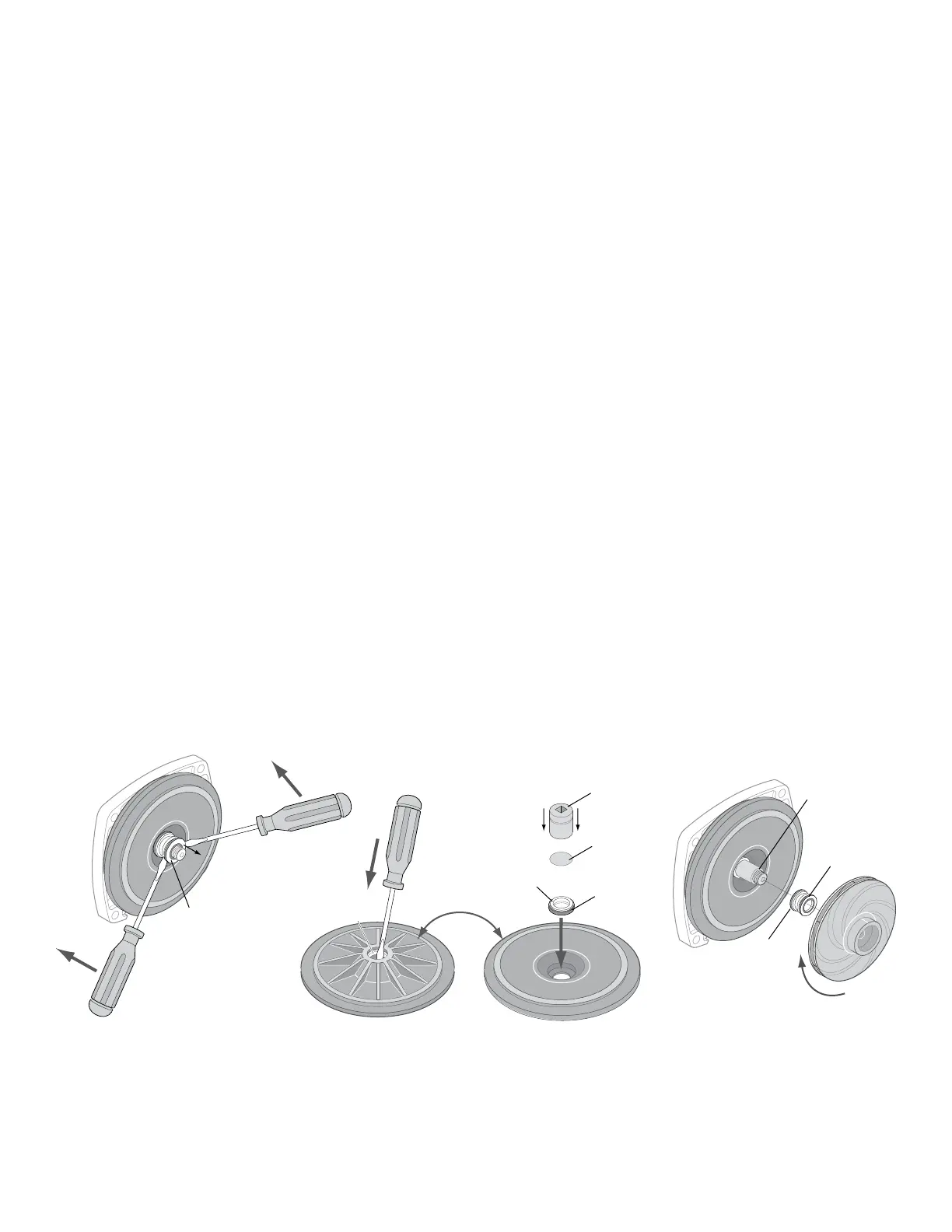

Seal Plate

Mechanical seal

rotating half

Mechanical seal

stationary half

A-Seal removal-rotating half B-Seal removal-stationary half C-Stationary half installation D-Rotating half installation

T

u

r

n

o

v

e

r

Polished

surface

Rubber

surface

Cardboard

washer

(supplied w/seal)

3/4" socket

or pipe

Sealing

face

Rubber drive

ring

Impeller

Shaft

shoulder

5939 0109

FIGURE 4

PUMP SERVICE

This centrifugal pump requires little or no service

other than reasonable care and periodic cleaning.

Occasionally, however, a shaft seal may become

damaged and must be replaced. The procedure as

outlined below will enable you to replace the seal.

NOTICE: These mechanical seals are supplied with

either a rubber seat ring or a sealing O-Ring. They are

completely interchangeable.

NOTICE: The highly polished and lapped faces of

this seal are easily damaged. Read instructions and

handle the seal with care.

Some models are equipped with an impeller screw,

which has a left hand thread. Before unscrewing the

impeller, remove the impeller screw.

REMOVAL OF OLD SEAL

1. After unscrewing impeller (Key No. 5, Page 6),

carefully remove rotating part of seal by prying up

on sealing washer, using two screwdrivers (see

Figure 4A). Use care not to scratch motor shaft.

2. Remove seal plate (Key No. 3) from motor and

place on flat surface, face down. Use a screwdriver

to push ceramic seat out from seal cavity (see

Figure 4B).

INSTALLATION OF FLOATING SEAT

(Figure 4C)

1. Clean polished surface of floating (ceramic) seat

with clean cloth.

2. Turn seal plate over so seal cavity is up; clean

cavity thoroughly.

3. Lubricate outside rubber surface or O-ring of

ceramic seat with soapy water and press firmly

into seal cavity with finger pressure. If seat will not

locate properly in this manner, place cardboard

washer over polished face of seat and press into

seal cavity using a 3/4” socket or 3/4” piece of

standard pipe.

4. Dispose of cardboard washer. Be sure polished

surface of seat is free of dirt and has not been

damaged by insertion. Remove excess soapy

water.

INSTALLATION OF ROTATING PART OF

SEAL UNIT (Figure 4D)

1. Reinstall seal plate using extreme caution not to hit

ceramic portion of seal on motor shaft.

2. Inspect shaft to make sure that it is clean.

3. Clean face of sealing washer with clean cloth.

4. Lubricate inside diameter and outer face of rubber

drive ring (see Figure 4D) with soapy water and

slide assembly on motor shaft (sealing face first)

until rubber drive ring hits shaft shoulder.

5. Screw impeller on shaft until impeller hub hits shaft

shoulder. This will automatically locate seal in place

and move the sealing washer face up against the

facing seat. Reinstall impeller screw (if used).

SERVICE

Loading...

Loading...