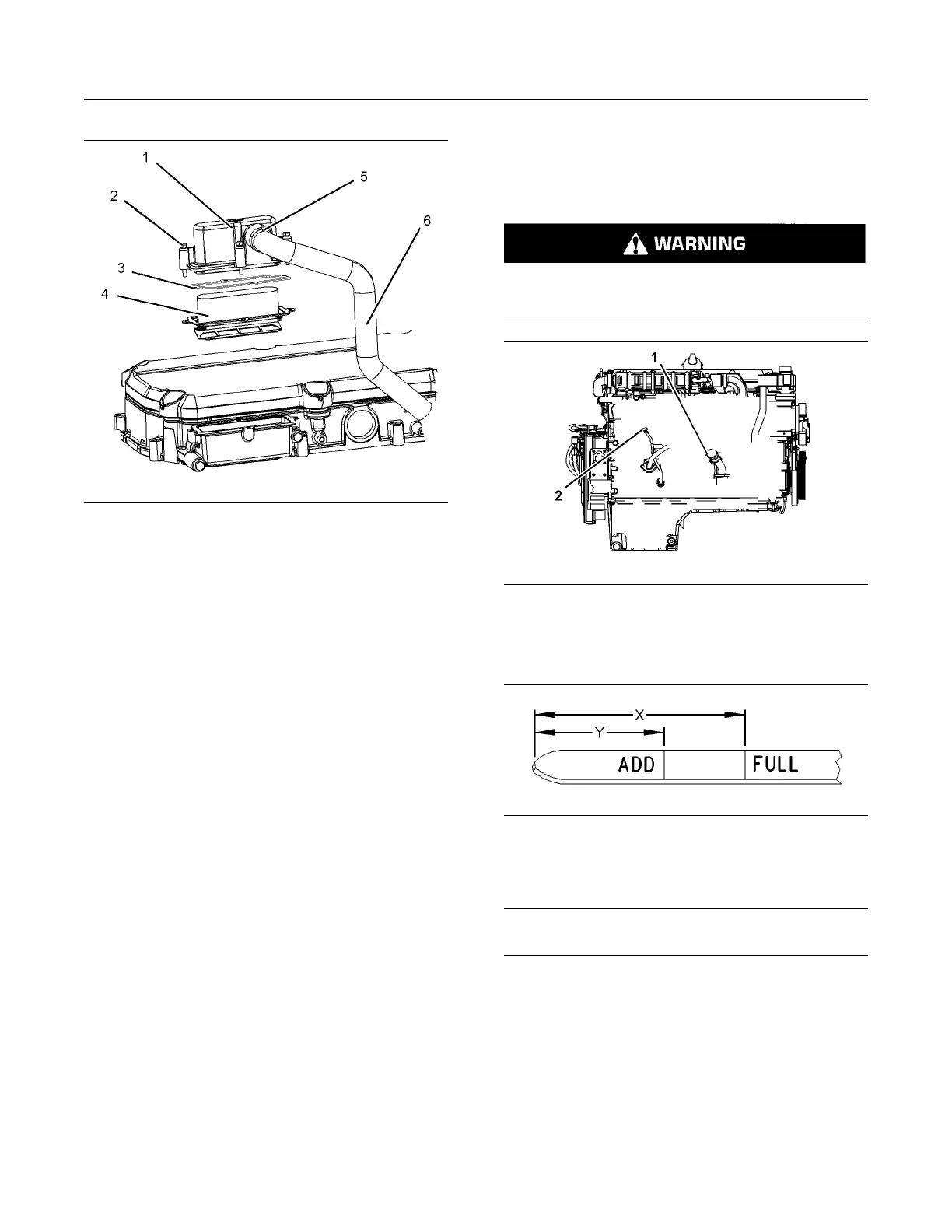

Illustration 82 g03810243

1. Loosen clip (5) and remove outlet hose (6). Ensure

that hose is clean internally and free from damage.

2. Remove bolts (2) and remove cover (1). Remove

gasket (3).

3. Remove element (4).

4. Install new element (4) and new gasket (3).

5. Install cover (1) and install all bolts (2). Tighten

bolts (2) to a torque of 12 N·m (106 lb in).

6. Install hose (6) with clip (5), tighten clip securely.

i02323089

Engine Mounts - Inspect

Note: The engine mounts may not have been

supplied by Perkins. Refer to the OEM information for

further information on the engine mounts and the

correct bolt torque.

Inspect the engine mounts for deterioration and for

correct bolt torque. Engine vibration can be caused

by the following conditions:

• Incorrect mounting of the engine

• Deterioration of the engine mounts

• Loose engine mounts

Any engine mount that shows deterioration should be

replaced. Refer to the OEM information for the

recommended torques.

i04288290

Engine Oil Level - Check

Hot oil and hot components can cause personal

injury. Do not allow hot oil or hot components to

contact the skin.

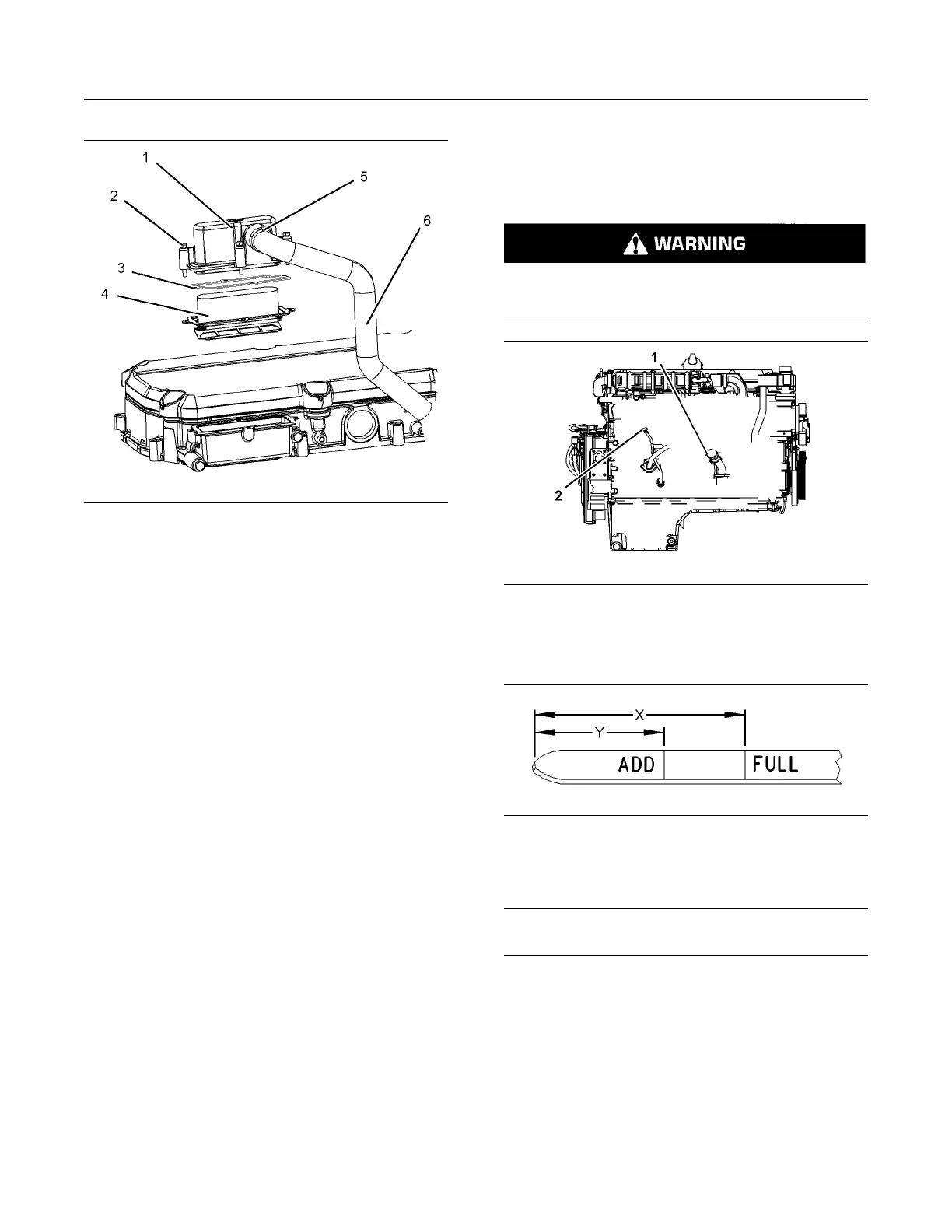

Illustration 83 g02455244

Typical installation of the oil level gauge

(1) Oil filler cap

(2) Oil level gauge

Illustration 84 g00110310

Partial view of the oil level gauge

(Y) “ADD” mark

(X) “FULL” mark

NOTICE

Perform this maintenance with the engine stopped.

SEBU9071-01

99

Maintenance Section

Engine Mounts - Inspect

Loading...

Loading...