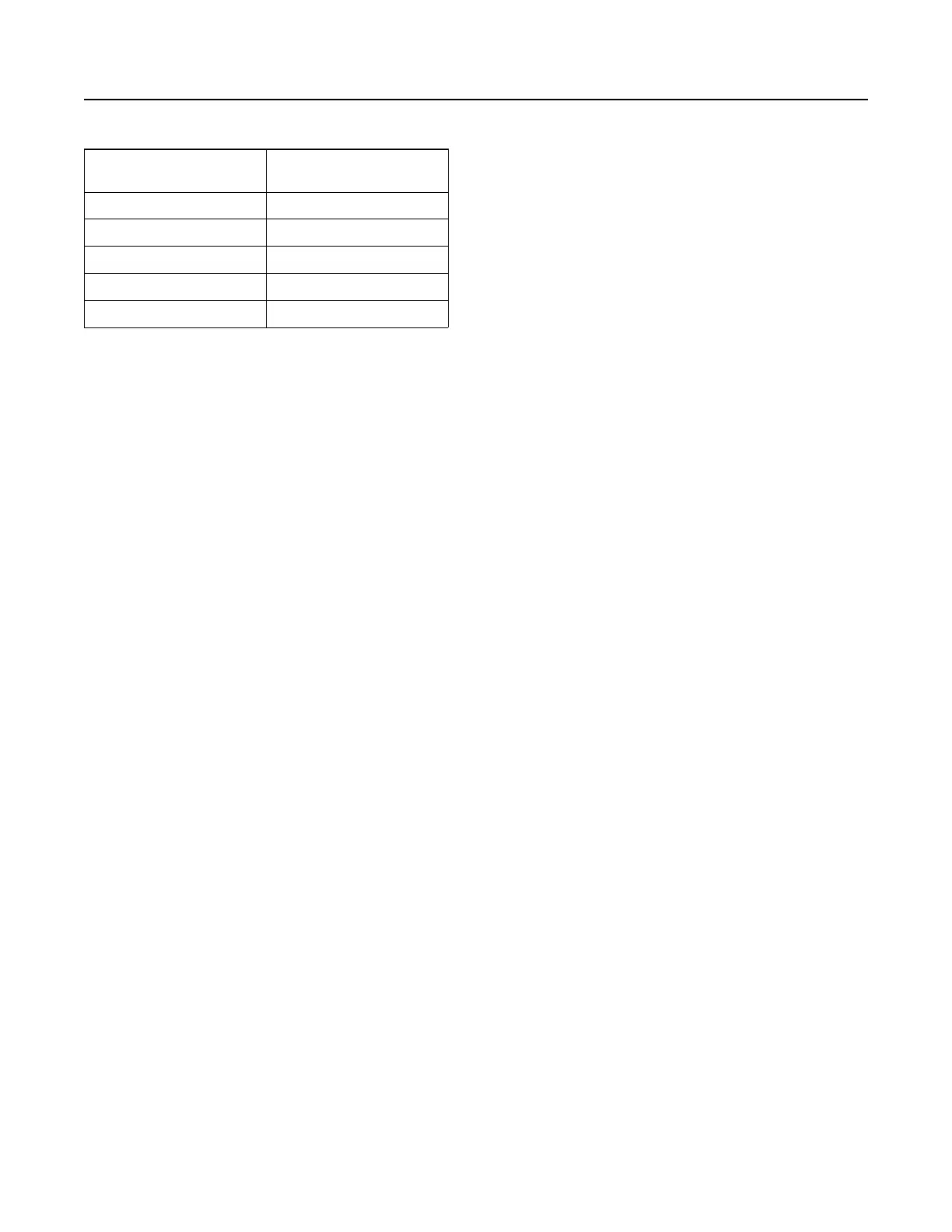

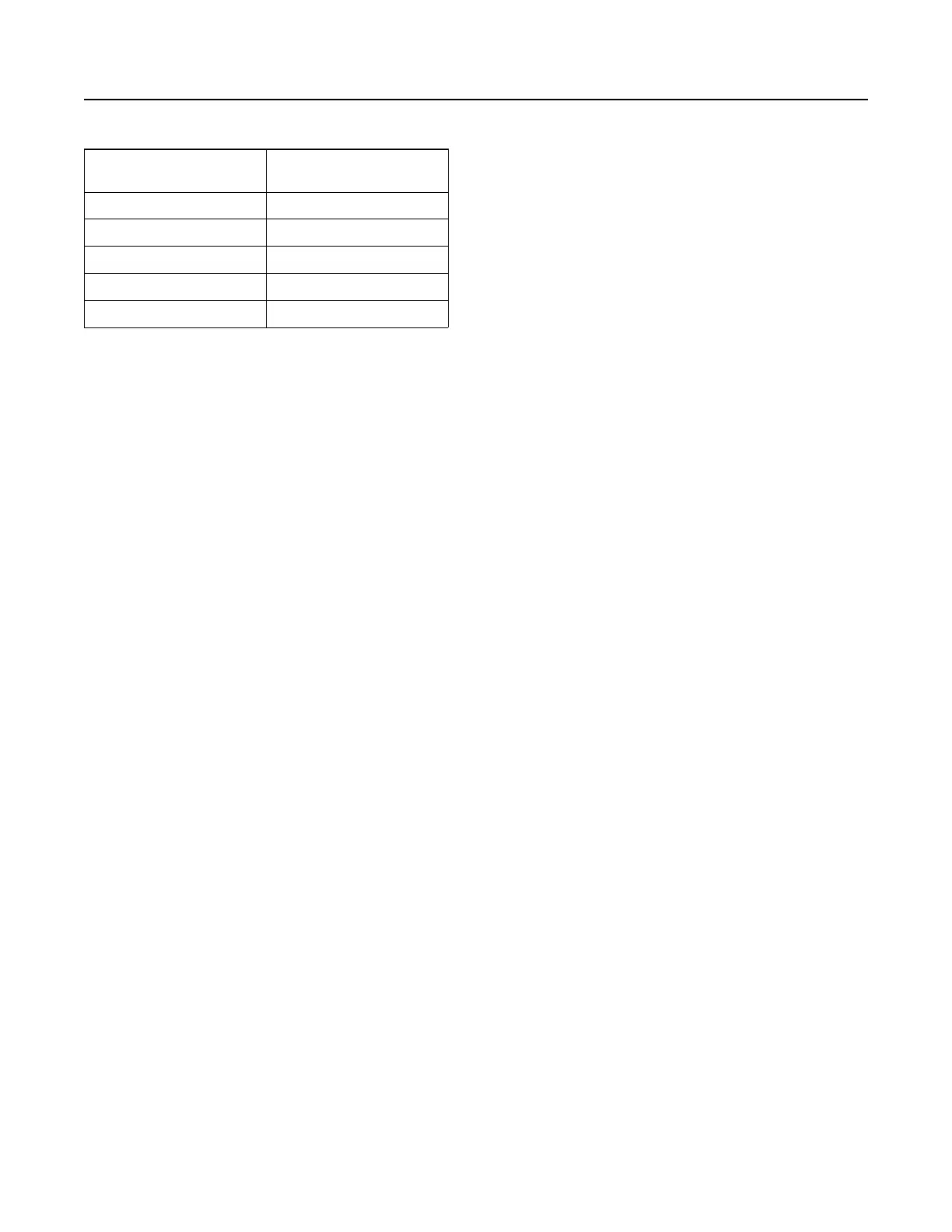

(Table 2, contd)

Aspiration Turbocharged and Turbo-

charged charge cooled

Compression Ratio

17:1

Displacement 2.8 L (170.87 cubic inch)

Firing Order

1-3 -4-2

Valves per cylinder

4

Rotation (flywheel end)

Counterclockwise

(1)

The operating rpm depends on the engine rating, the applica-

tion, and the configuration of the throttle.

Electronic Engine Features

The engine and aftertreatment operating conditions

are monitored. The Electronic Control Module (ECM)

controls the response of the engine to these

conditions and to the demands of the operator. These

conditions and operator demands determine the

precise control of fuel injection by the ECM. The

electronic engine control system provides the

following features:

• Engine monitoring

• Engine speed governing

• Control of the injection pressure

• Cold start strategy

• Automatic air/fuel ratio control

• Torque rise shaping

• Injection timing control

• System diagnostics

• NOx reduction system control

• Aftertreatment system control

The ECM provides an electronic governor that

controls the injector output to maintain the desired

engine speed.

For more information on electronic engine features,

refer to the Operation and Maintenance Manual,

“Features and Controls” topic (Operation Section).

Engine Diagnostics

The engine has built-in diagnostics to ensure that the

engine systems are functioning correctly. The

operator will be alerted to the condition by a “Stop or

Warning” lamp. Under certain conditions, the engine

horsepower and the vehicle speed may be limited.

The electronic service tool may be used to display

the diagnostic codes.

There are three types of diagnostic codes: active,

logged, and event.

Most of the diagnostic codes are logged and stored in

the ECM. For additional information, refer to the

Operation and Maintenance Manual, “Engine

Diagnostics” topic (Operation Section).

Engine Cooling and Lubrication

The cooling system and lubrication system consists

of the following components:

• Belt driven water pump

• Water temperature regulator which regulates the

engine coolant temperature

• Gear-driven gerotor type oil pump

• Oil cooler

The engine lubricating oil is supplied by a gerotor

type oil pump. The engine lubricating oil is cooled

and the engine lubricating oil is filtered. The bypass

valve can provide unrestricted flow of lubrication oil to

the engine if the oil filter element should become

plugged.

Engine efficiency, efficiency of emission controls, and

engine performance depend on adherence to proper

operation and maintenance recommendations.

Engine performance and efficiency also depend on

the use of recommended fuels, lubrication oils, and

coolants. Refer to this Operation and Maintenance

Manual, “Maintenance Interval Schedule” for more

information on maintenance items.

Engine Service Life

Engine efficiency and maximum utilization of engine

performance depend on the adherence to proper

operation and maintenance recommendations. In

addition, use recommended fuels, coolants, and

lubricants. Use the Operation and Maintenance

Manual as a guide for required engine maintenance.

M0092609-05 35

Product Information Section

Product Description

Loading...

Loading...