4

26 User’s Handbook, TPD 1285E, Issue 2

3.152

Atomiser fault

Warnings!

z Ensure that the fuel does not spray onto your skin.

z Keep away from moving parts during engine operation. Some moving parts cannot be seen clearly while

the engine runs.

An atomiser fault can cause an engine misfire.

In order to find which atomiser is defective, operate the engine at a fast idle speed. Loosen and tighten the

union nut of the high-pressure fuel pipe at each atomiser. When the union nut of the defective atomiser is

loosened, it has little or no effect on the engine speed.

How to renew an atomiser

Warning! Do not allow dirt to enter the fuel system. Before a connection is disconnected, clean thoroughly the

area around the connection. After a component has been disconnected, fit a suitable cover to all open

connections.

1 Remove the fuel leak-off pipe.

2 Remove the union nuts of the high-pressure pipe from the atomiser and from the fuel injection pump. Do not

bend the pipe. If necessary, remove the pipe clamps.

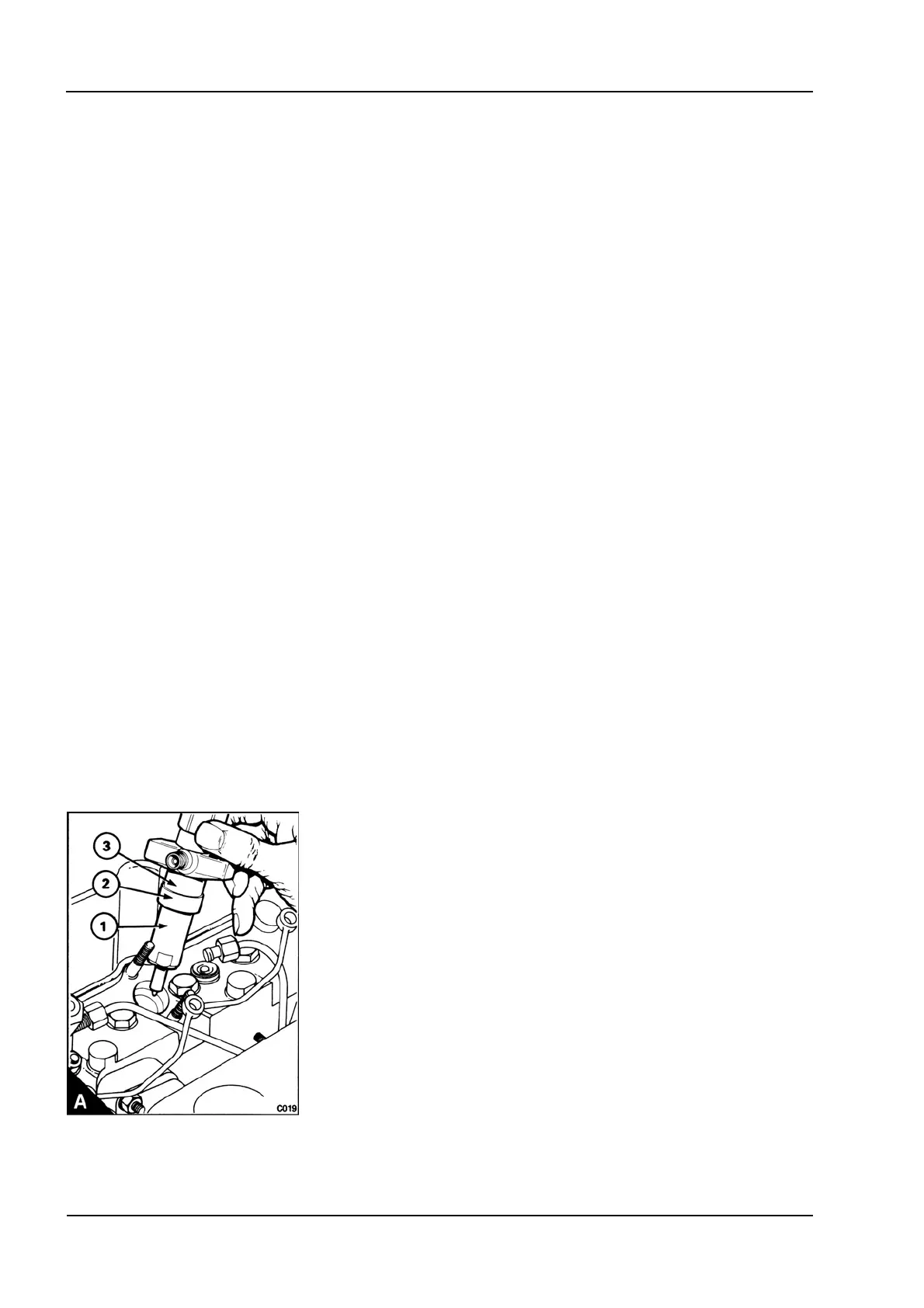

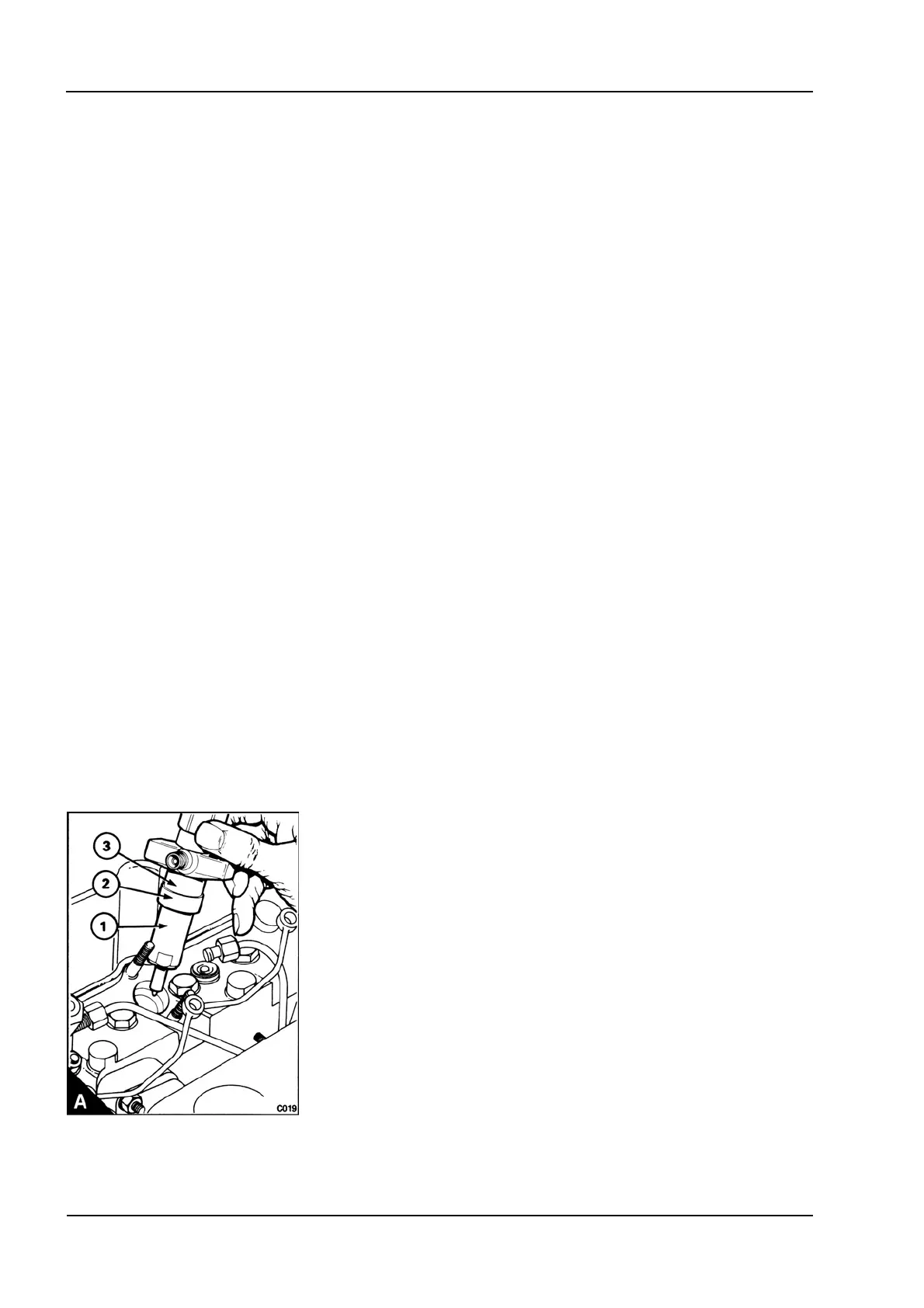

3 Remove the atomiser flange nuts and remove the atomiser (A1) and its seat washer. Remove the dust seal

(A2) and the spacer (A3) and fit the spacer and a new dust seal on the new atomiser.

4 Put the new atomiser in position with its spacer, new dust seal and a new seat washer. Ensure that the fuel

leak-off connection is not toward the engine. Ensure that the atomiser is not tilted and tighten the flange nuts

evenly and gradually to 16 Nm (12 Ibf ft) 1,7 kgf m. If the atomiser is retained by a separate clamp, tighten the

nuts to 12 Nm (9 Ibf ft) 1,2 kgf m.

Warning! Do not tighten the nuts of the high pressure pipes more than the recommended torque tension. If

there is a leakage from the union nut, ensure that the pipe is correctly aligned with the atomiser inlet. Do not

tighten the atomiser union nut more, as this can cause a restriction at the end of the pipe. This can affect the

fuel delivery.

5 Fit the high-pressure fuel pipe and tighten the union nuts to 22 Nm (16 Ibf ft) 2,2 kgf m. If necessary, fit the

pipe clamps.

6 Renew the aluminium washers and fit the leak-off pipe.

7 Operate the engine and check for leakage of fuel and air.

This document has been printed from SPI². Not for Resale

Loading...

Loading...